Business suit rolled collar template making method and business suit

A technology for lapel collars and suits, which is applied to clothing, sewing tools, clothing, etc. It can solve the problems of not being close to the body, affecting the appearance of the suit and the comfort of the human body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

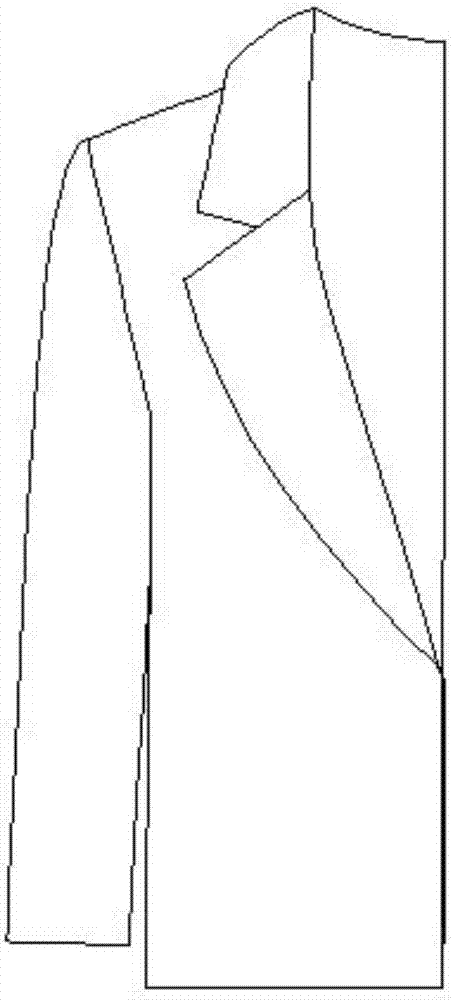

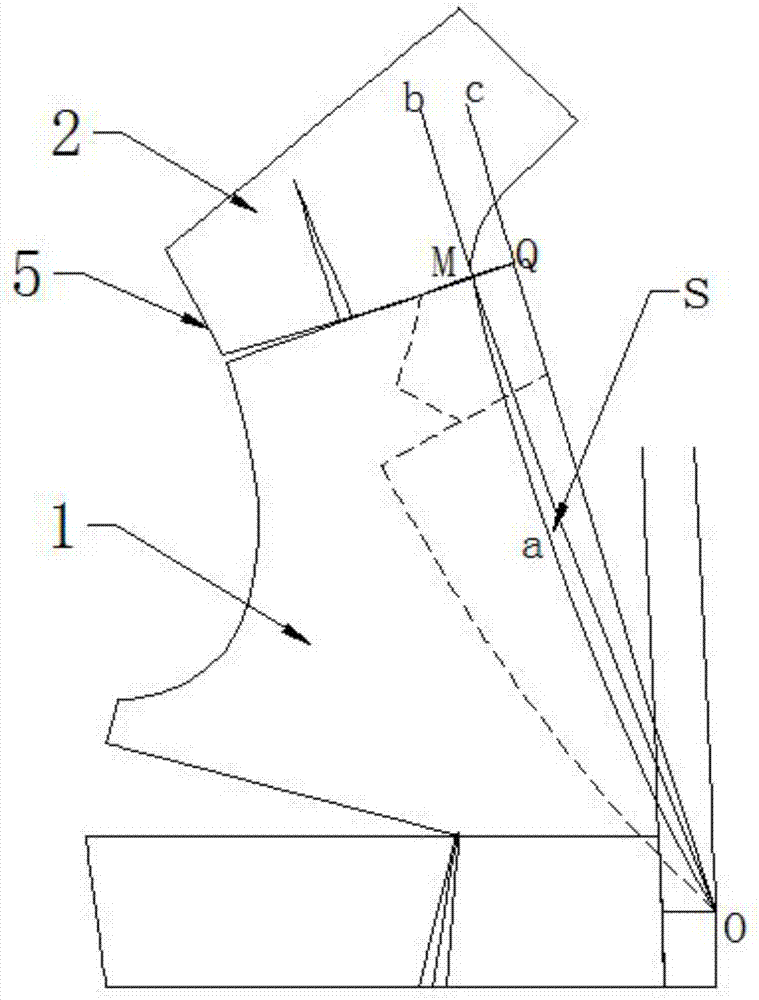

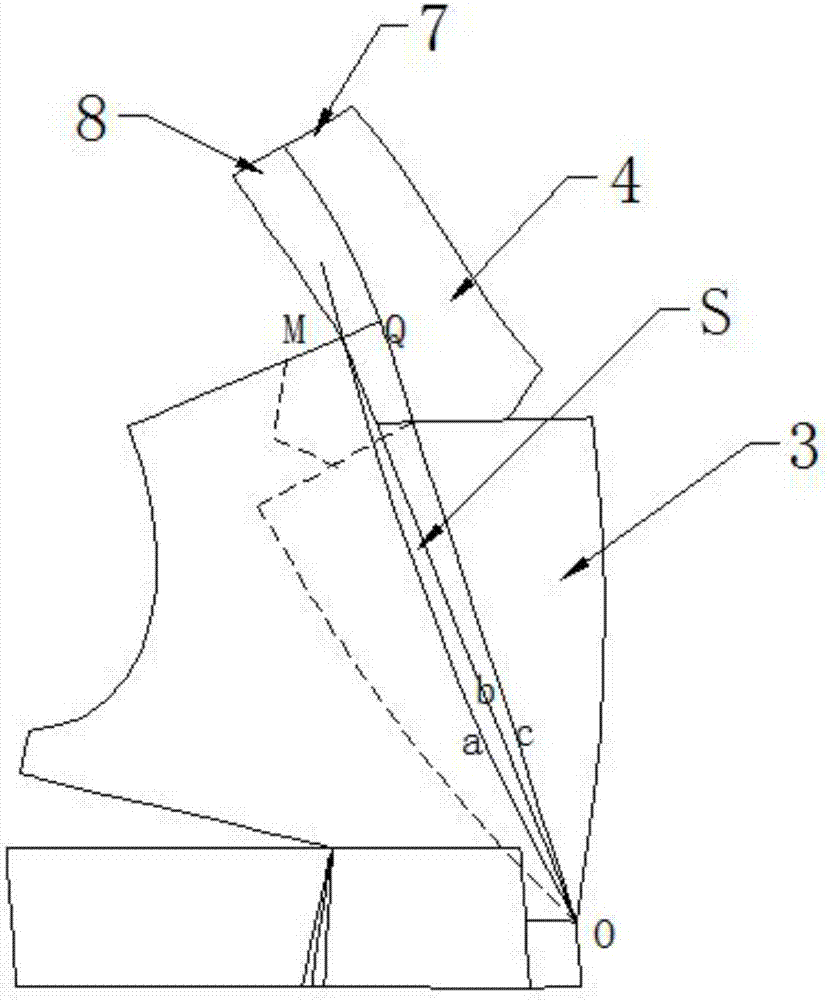

[0028] refer to Figure 2 to Figure 5 , is the tailoring step chart of the suit lapel collar plate-making method, combined with Figure 6 , is a structural diagram of the lapel style after tailoring the suit lapel collar plate-making method according to the present invention. In order to clearly show the technical characteristics of the present invention, some structures are omitted, and some structures are shown with dotted lines. For example, in figure 2 The dotted line in indicates the preset contour line of the lapel lapel lapel during plate making, Figure 4 The direction of the arrow shown in means the rotation direction of the first blade. Correspondingly, the dotted line on the right side of the first blade indicates the position of the outer contour line before rotation.

[0029] Such as Figure 2 to Figure 6 As shown in , the suit lapel collar plate-making method provided by the present invention is applied to auxiliary plate-making and tailoring of garment pieces...

Embodiment 2

[0040] The present invention also provides a suit, which includes a lapel sewn on the body, and its structure is as follows: Figure 6 As shown in , the finished version is made by adopting the plate-making method of the turned-up collar of the suit described in the first embodiment above. The turned-up collar is assisted by the tailoring of the finished version. The problem of empty head is more comfortable and more beautiful after wearing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com