Dry dedusting, decoking, desulfurizing and defluorinating apparatus suitable for aluminum industry

A dry dedusting and defluorination technology, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of small manufacturers such as high cost, no cooperation relationship, large scale, etc., achieve a high degree of integration and avoid waste , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described in detail below through specific embodiments.

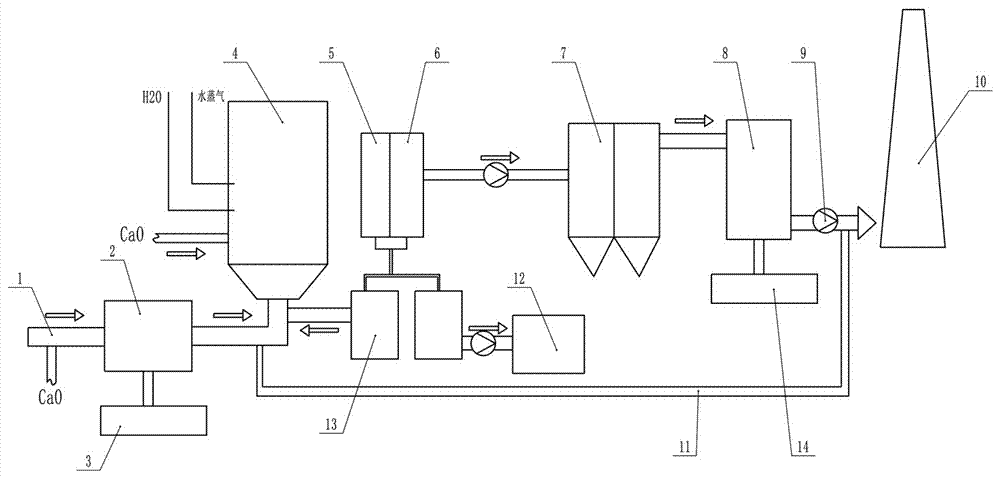

[0023] A dry dust removal, coking, desulfurization and defluorination device suitable for the aluminum industry, comprising a decoking unit, a desulfurization unit, a defluorination unit and a chimney that are serially connected in series, and the decoking unit includes CaO installed in the flue gas pipeline 1 Powder nozzle, the outlet of the flue gas duct 1 is connected to the pre-dust collector 2, the chip discharge port of the pre-dust collector 2 is connected to the first vibrating screen 3, and the pre-dust collector 2 can use conventional cyclone separators, multi-tube dust collectors, etc. Dust removal equipment; the desulfurization unit includes a fluidized bed absorption tower 4, a mechanical dust collector 5 and a first bag filter 6, the bottom end of the fluidized bed absorption tower 4 is the intake end, and the intake end is installed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap