Connecting rod clamping device

A connecting rod clamp and connecting rod technology, which is applied in the direction of chucks, manipulators, program control manipulators, etc., can solve problems such as product jaw damage, and achieve the effect of simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

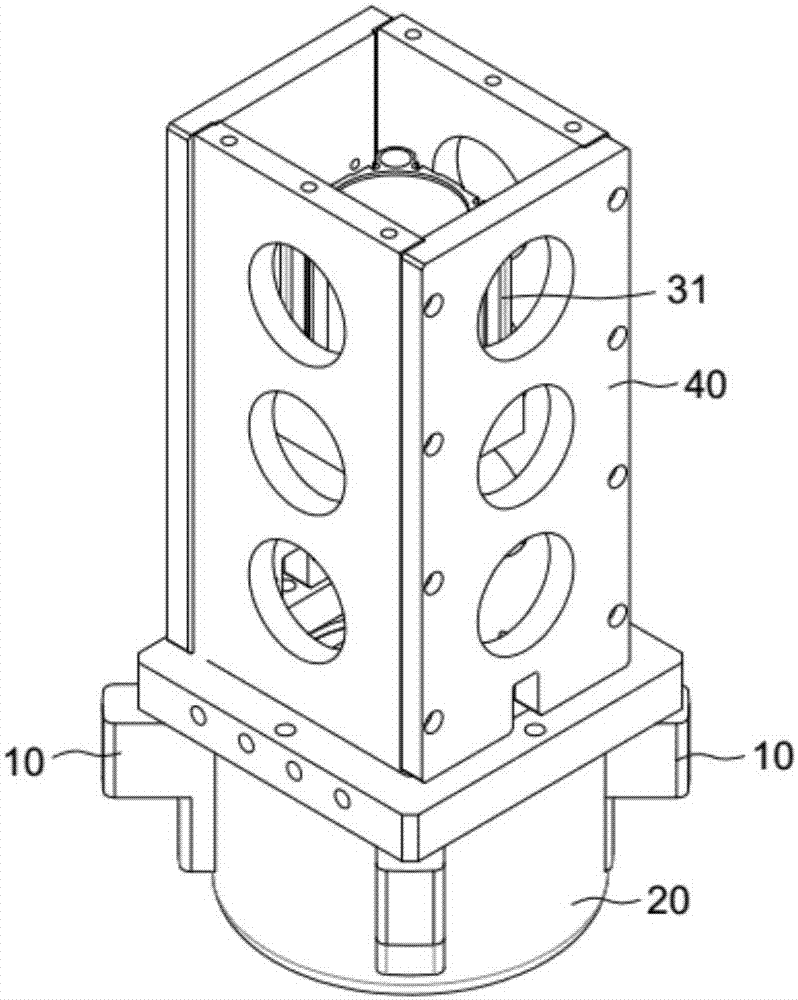

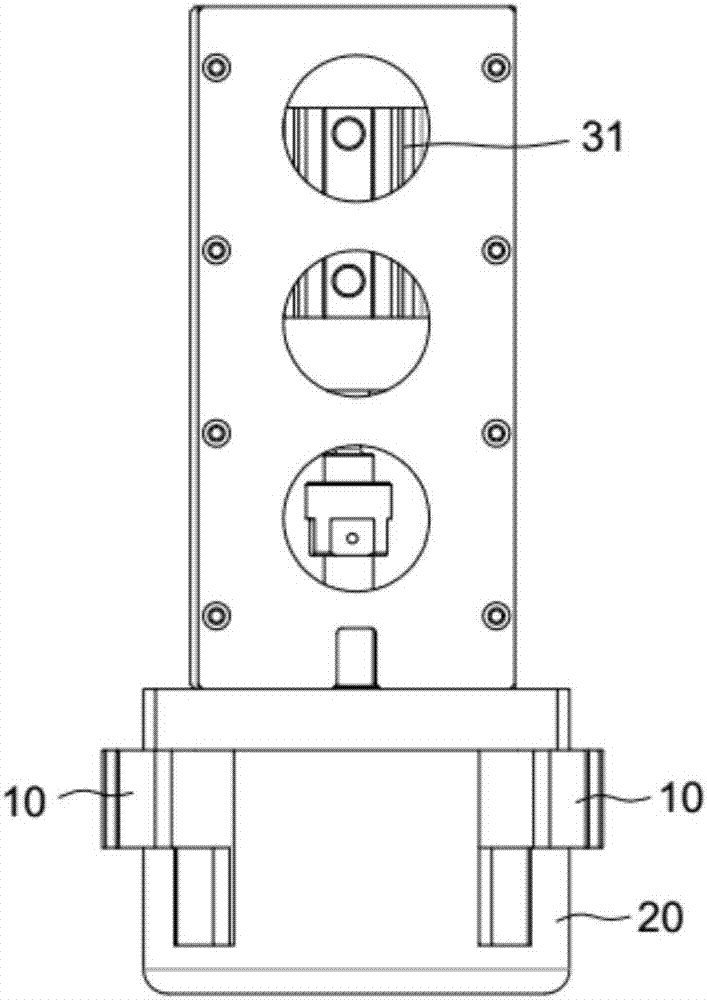

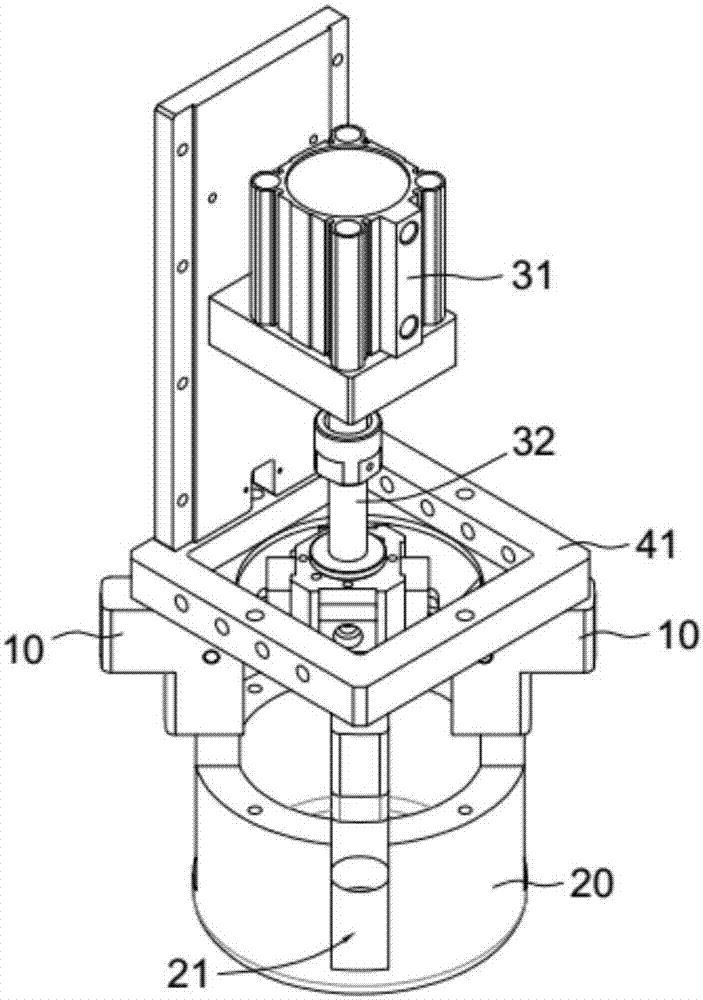

[0030] refer to figure 1 , figure 2 , a connecting rod clamping device, including a linear power assembly installed on the device frame, a connecting rod 11 connected to the linear power assembly, a jaw 10 connected to the connecting rod, fixed on the device frame The product positioning body 20.

[0031] refer to image 3 , Figure 4 , the product positioning body 20 is cylindrical, the top of the product positioning body 20 is open, the bottom of the product positioning body is provided with a bottom plate, and four chutes 21 are opened on the side wall of the product positioning body, and the four chutes are evenly distributed along the circumferential direction of the product positioning body . Described chute 21 is to offer the vertical bar-shaped notch on the side wall of product positioning body, and this vertical bar-shaped notch is opened to the bottom surface of the cavity in product positioning body 20, namely the bottom surface of chute and the top surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com