Anti-splashing funnel for granular oil injection of die-casting machine

A technology of granular oil and die-casting machine, which is used in funnel, bottle filling, packaging, etc., can solve the problems of granular oil rebounding and splashing, easy to cause fire, affecting sanitation, etc., to reduce air pressure thrust, eliminate fire safety hazards, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

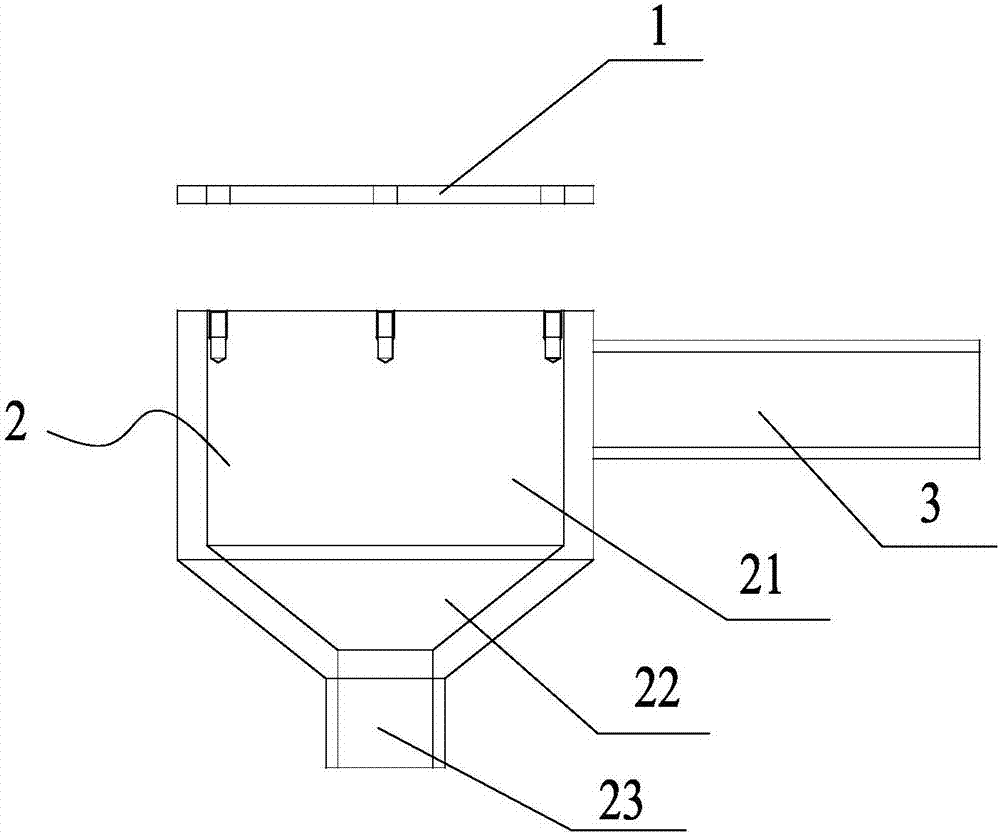

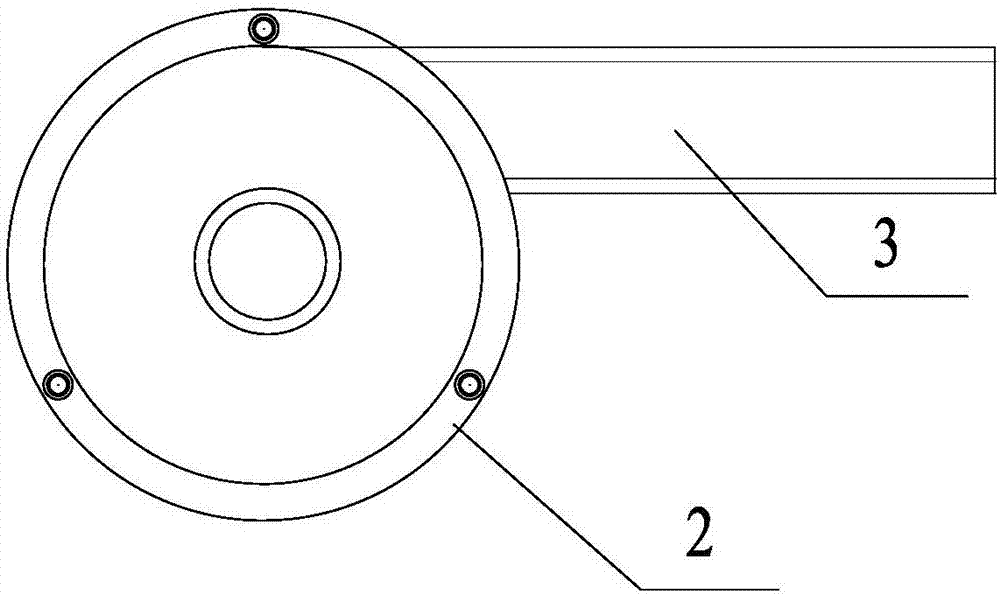

[0014] Such as figure 1 Shown: Die casting machine grain oil injection splash funnel, including cover plate 1, funnel body 2 and oil inlet pipe 3. The funnel body 2 includes a cylindrical part 21 connected in sequence, an inverted truncated conical part 22 and an oil outlet 23. The diameter of the cylindrical part 21 is consistent with the diameter of the bottom surface of the truncated conical part 22, and the diameter of the oil outlet 23 is consistent with that of the truncated conical part 22. The cover plate 1 utilizes three screws to fix the upper end of the cylindrical part 21 . The wall thickness of the cylindrical part 21 is 3-6 mm. In one embodiment, the wall thickness of the cylindrical part 21 is 5 mm, which ensures the structural stability under the impact of particle oil and facilitates the fixing of the cover plate 1 on the cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com