Antiskid reducer sealing cover for electric power

A technology of reducer and sealing cover, which is applied in the direction of mechanical equipment, transmission parts, belts/chains/gears, etc. It can solve the problems of affecting the working efficiency of the reducer, easy loosening of the inner flange of the cover, and inconvenient opening of the cover. Achieve the effect that it is not easy to take off, improve work efficiency, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

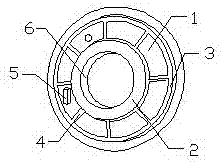

[0015] See figure 1 , The present invention is an anti-skid reducer sealing cover for electric power, which includes a reducer cover body 1, the reducer cover body 1 is in a circular ring shape, and the front of the reducer cover body 1 is respectively provided with inner protrusions from the inside to the outside. The rim 2 and the outer flange 3, the inner flange 2 and the outer flange 3 are both annular, the inner flange 2 and the outer flange 3 are connected by at least two reinforcing ribs 4, the At least one stopper 5 is provided between the inner flange 2 and the outer flange 3 and on the reducer cover body 1. The surface of the inner flange 2 is provided with a non-slip layer 6, which is convenient for the operator to open the cover and is not easy to take off.

[0016] The setting of the stopper 5 makes the connection between the reducer cover and the body more firm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com