Air processing system for freezing and refrigerating cabinet performance testing device

An air handling system and testing device technology, applied in household refrigeration devices, cooling fluid circulation devices, applications, etc., can solve the problems of the refrigeration circuit being unsuitable for air, the influence of life, and the limited dehumidification effect of the evaporator, so as to enhance the dehumidification effect, The effect of avoiding damage and large humidity adjustment margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

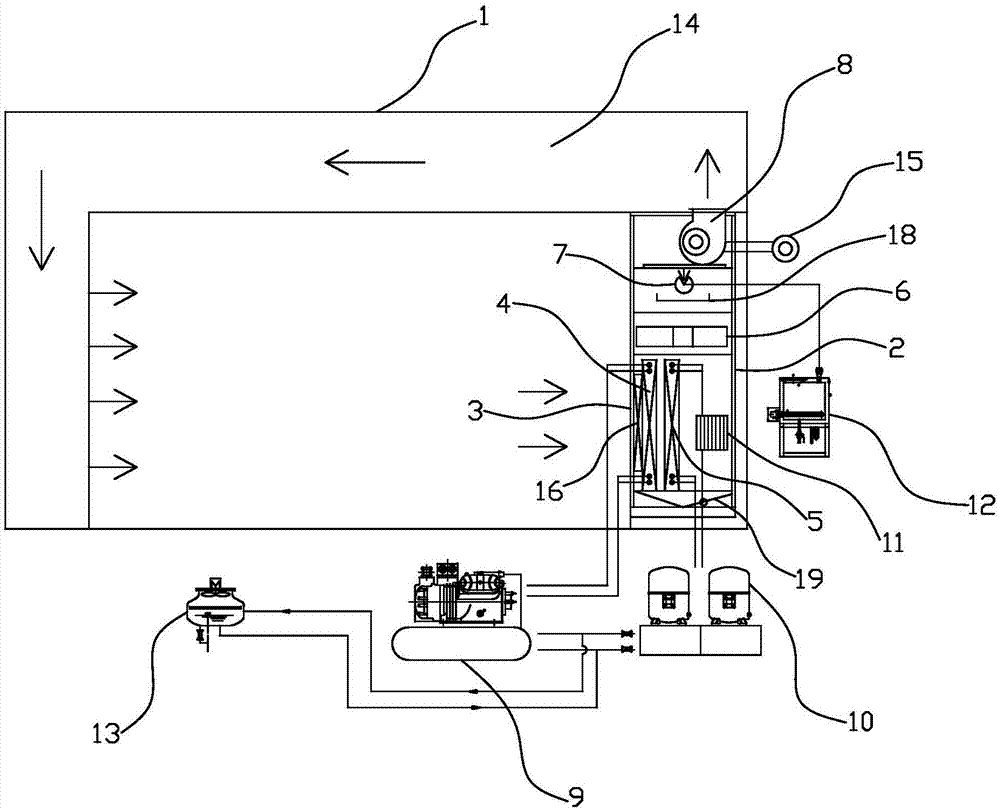

[0031] Such as figure 1 As shown, the present invention includes a unit box 2 arranged in the test room 1, the unit box 2 is provided with a return air outlet 3 for air to enter and has a primary filter, and the unit box 2 is provided with The first evaporator 4, the second evaporator 5, the rear electric heater 6, the nozzle pipe 7 connected with the dry steam humidifier 12 and the fan 8 arranged in sequence along the air flow direction, the rear electric heater 6 Located above the air outlet area of the second evaporator 5, the first evaporator 4 is matched with the first compression condensing unit 9, the second evaporator 5 is matched with the second compression condensing unit 10, and the unit box 2 is also provided with a bypass air valve 11 that directly discharges part of the air that enters the unit box 2 from the air return port 3 .

[0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com