Automotive suspension spiral spring durability test device

A durability test, coil spring technology, used in measurement devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as reduced comfort, reduced vehicle handling, and offset of vehicle center of gravity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

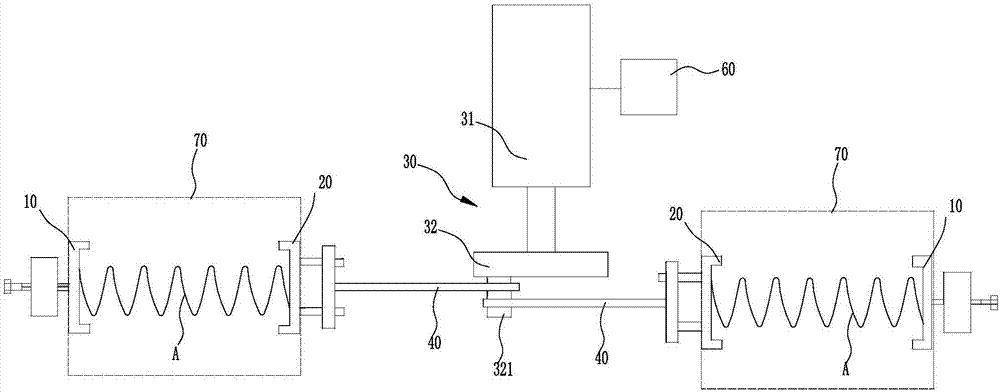

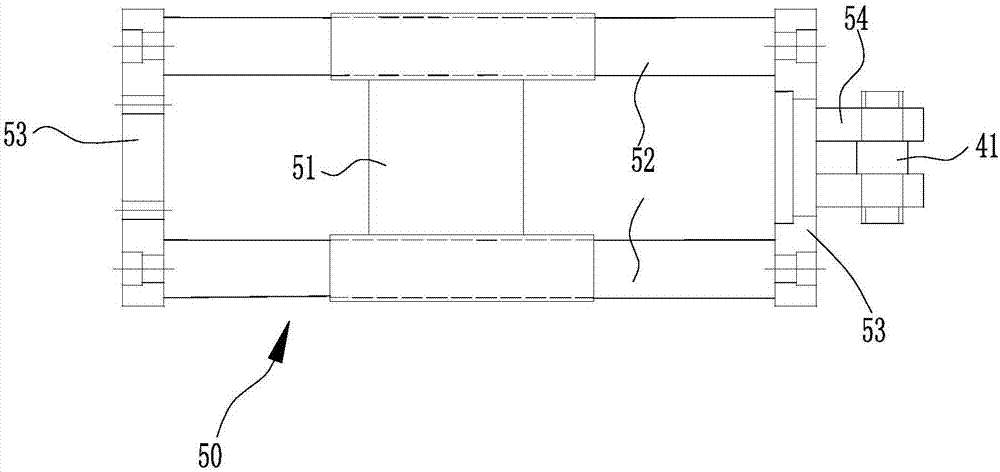

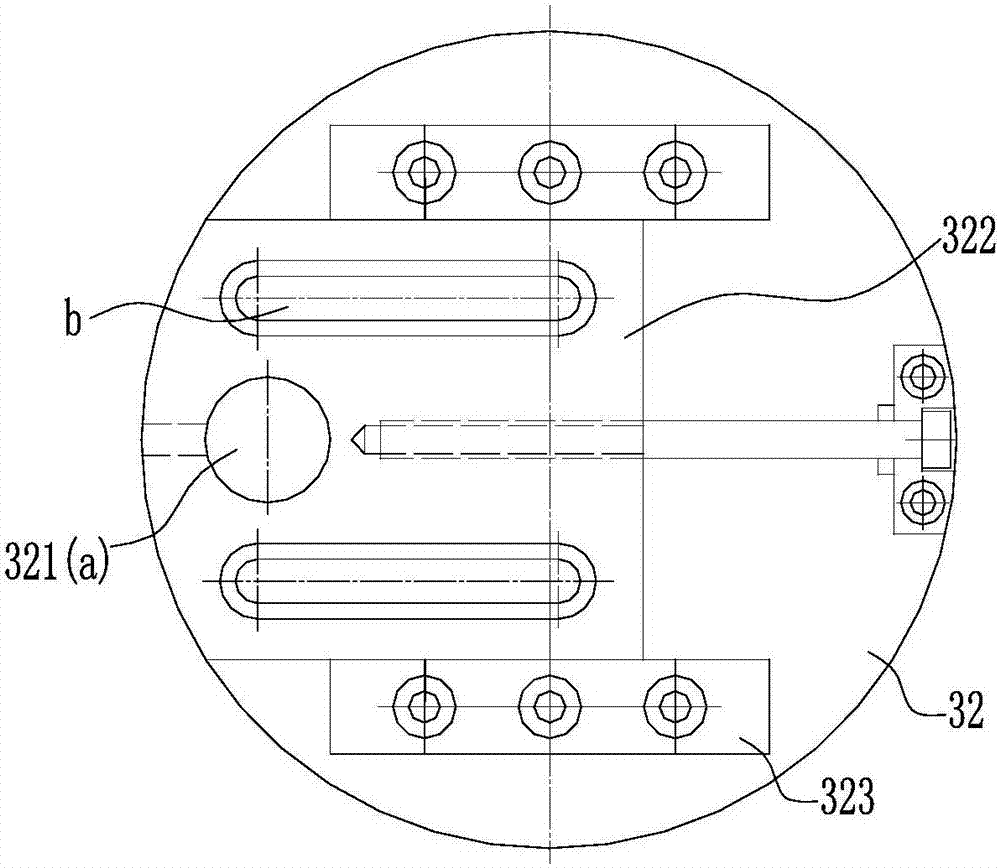

[0009] An automobile suspension coil spring durability test device, comprising a fixed bracket 10 connected to one end of the coil spring A and a movable bracket 20 connected to the other end of the coil spring A, the movable bracket 20 is connected to a driving mechanism 30, and the driving mechanism 30 is connected to There are at least two sets of movable brackets 20 and coil springs A, so that some coil springs A perform stretching motion while the rest of the coil springs A perform compression motion. Because the coil spring A has the function of energy storage, the law of energy conservation and the principle of action and reaction force are cleverly used, and at the same time, multiple coil spring A tests can be completed in one test, so the test efficiency is almost doubled and the test cycle is shortened. , reducing costs.

[0010] Such as figure 1 As shown, the drive mechanism 30 includes a variable frequency motor 31, the output shaft of the variable frequency moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com