Touch display screen

A touch display, liquid crystal display technology, applied in optics, instruments, electrical and digital data processing, etc., can solve the problems that the static electricity of the thin film sensor cannot be exported, the sensitivity of the thin film sensor is affected, and the operation command is misjudged, etc. Better, touch-sensitive, cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solution of the present invention is further described, but the present invention is not limited to these examples.

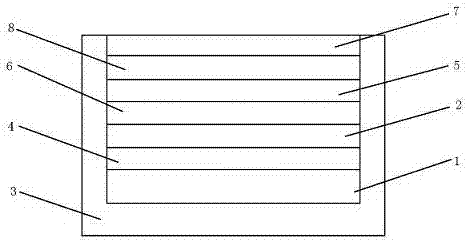

[0010] Such as figure 1 As shown, a touch display screen includes: a liquid crystal display screen 1, a No. 1 thin film sensor layer 2 and a housing 3, and it is characterized in that the No. 1 thin film sensor layer 2 is connected to the liquid crystal display through a No. 1 OCA optical adhesive layer 4 The screen 1 is bonded; the liquid crystal display screen 1 and the No. 1 film sensor layer 2 are installed in the shell 3 . When the No. 1 thin film sensor layer 2 is touched, an electronic signal will be sent back to the inside of the IC to realize the touch effect; the hardness of the No. 1 thin film sensor layer 2 will be above 2H by adding a coating on the No. 1 thin film sensor layer 2 to increase the hardness.

[0011]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com