High-speed seeder

A seeder, high-speed technology, applied in the field of agricultural machinery, can solve the problems affecting the effect of sowing, close contact with soil, uneven seed distance, etc., and achieve the effect of uniform distance, stable ditch depth, and even seed ditch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

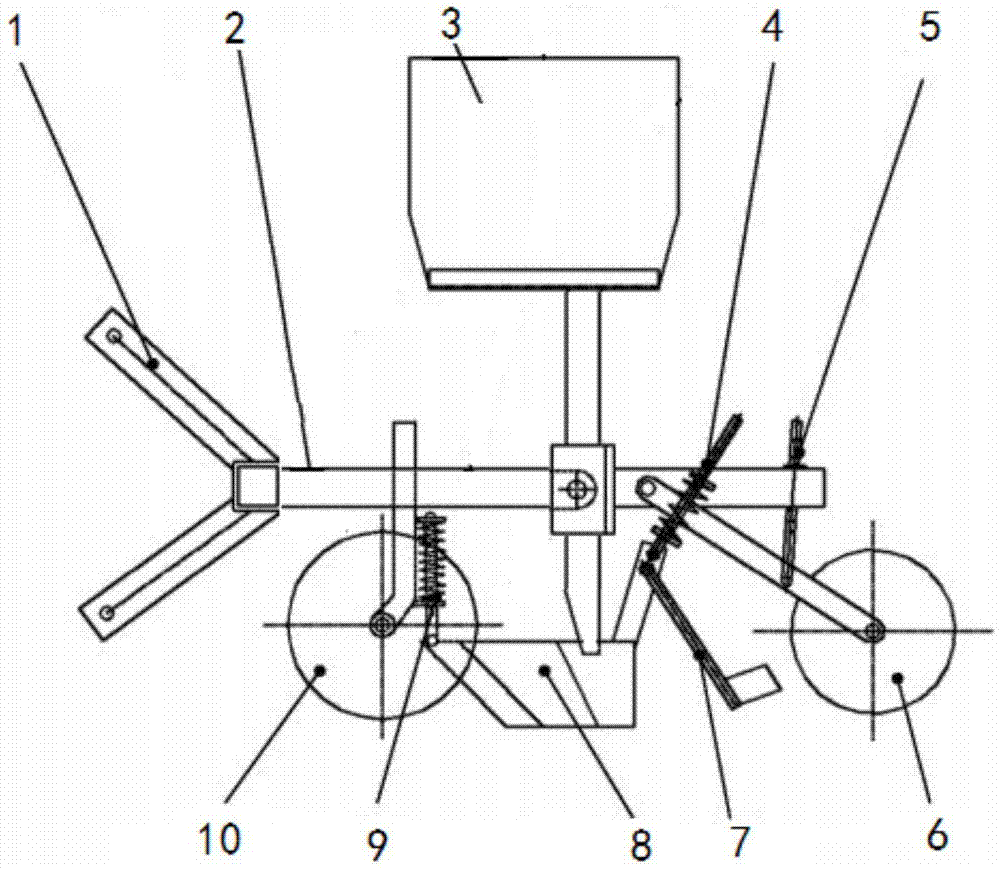

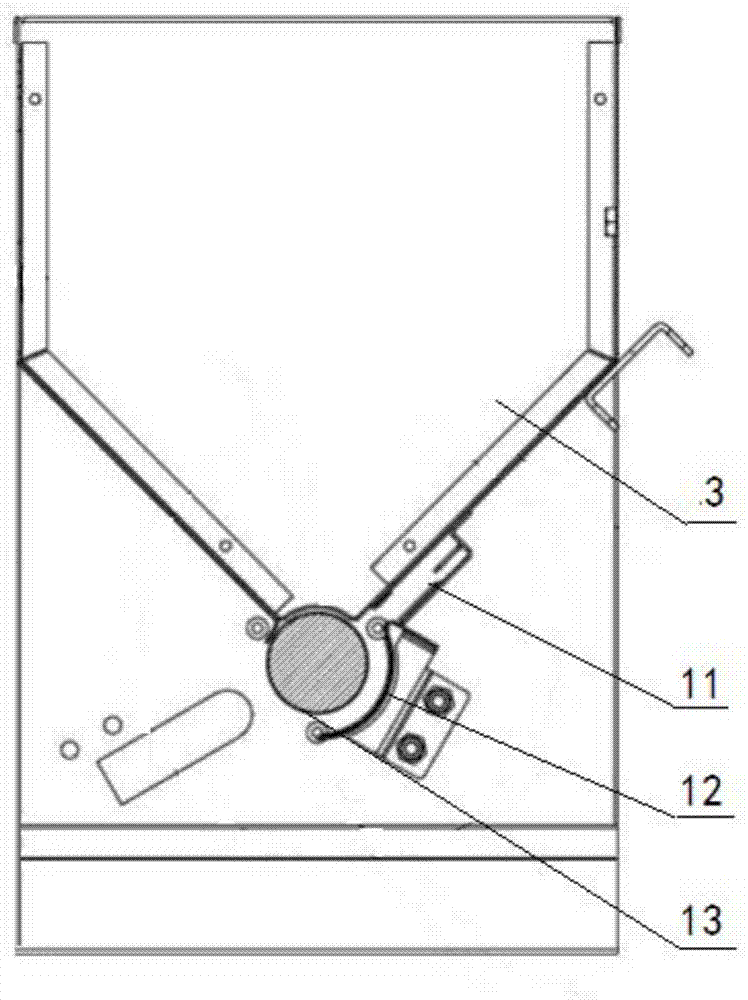

[0024] A high-speed seeder includes a frame assembly 1 , a seeding box 3 , a sowing unit frame 2 , a disc opener 10 , a slide knife opener 8 , a soil cover 7 , and a suppression depth-limiting wheel 6 . The sowing single frame 2 is connected with the frame assembly 1, and the seeding box 3 is arranged on the sowing single frame 2; And the suppression depth gauge wheel 6 is sequentially arranged on the sowing unit frame 2 from front to back, and the diameter of the suppression depth gauge wheel 6 is smaller than the diameter of the disc opener 10 . The seeding box 3 is arranged in the middle of the sowing unit frame 2, and the discharge opening at the bottom of the seeding box 3 is located at the rear side of the sliding knife opener 8. The seeding box 3 is provided with a sowing mechanism; the sowing mechanism includes a deflector 12, a sowing wheel and a sowing shaft 13; the sowing shaft 13 runs through a pair of side walls of the sowing box 3 transversely; A deflector 12 is...

Embodiment 2

[0026] A high-speed seeder includes a frame assembly 1 , a seeding box 3 , a sowing unit frame 2 , a disc opener 10 , a slide knife opener 8 , a soil cover 7 , and a suppression depth-limiting wheel 6 . The sowing single frame 2 is connected with the frame assembly 1, and the seeding box 3 is arranged on the sowing single frame 2; And the suppression depth gauge wheel 6 is sequentially arranged on the sowing unit frame 2 from front to back, and the diameter of the suppression depth gauge wheel 6 is smaller than the diameter of the disc opener 10 . The seeding box 3 is arranged in the middle of the sowing unit frame 2, and the discharge opening at the bottom of the seeding box 3 is located at the rear side of the sliding knife opener 8. The planter also includes a rear pressure spring 4 of the opener, a sowing depth adjustment rod 5 and a front pressure spring 9 of the opener; Deep adjusting rod 5, the front portion and the rear portion of slide knife ditch opener 8 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com