High-throughput micron particle circular sorting and concentrating device and manufacturing method thereof

A technology of micron particles and concentrating devices, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problem of inability to complete real-time detection in analysis time, increased chip bonding requirements, uneven chip flow, etc. problems, to achieve the effect of increasing safety and stability, simple structure and manufacturing process, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to better understand the present invention, the content of the present invention is further described below in conjunction with the embodiments, but the content of the present invention is not limited to the following embodiments.

[0045] working principle:

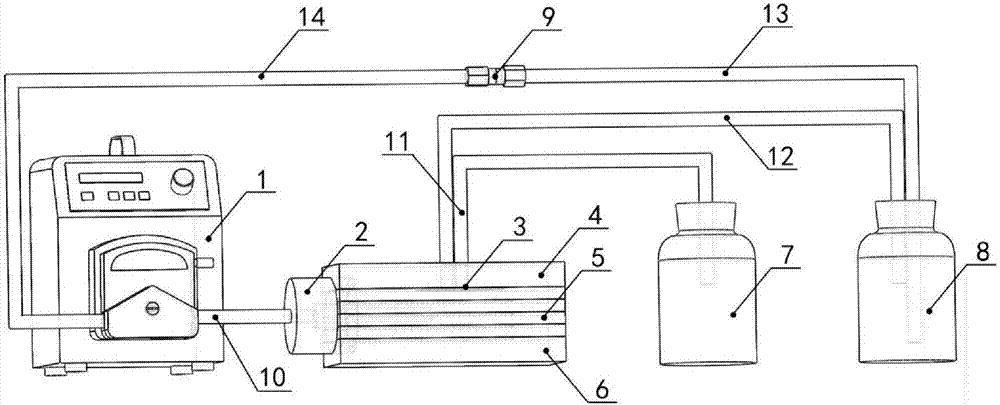

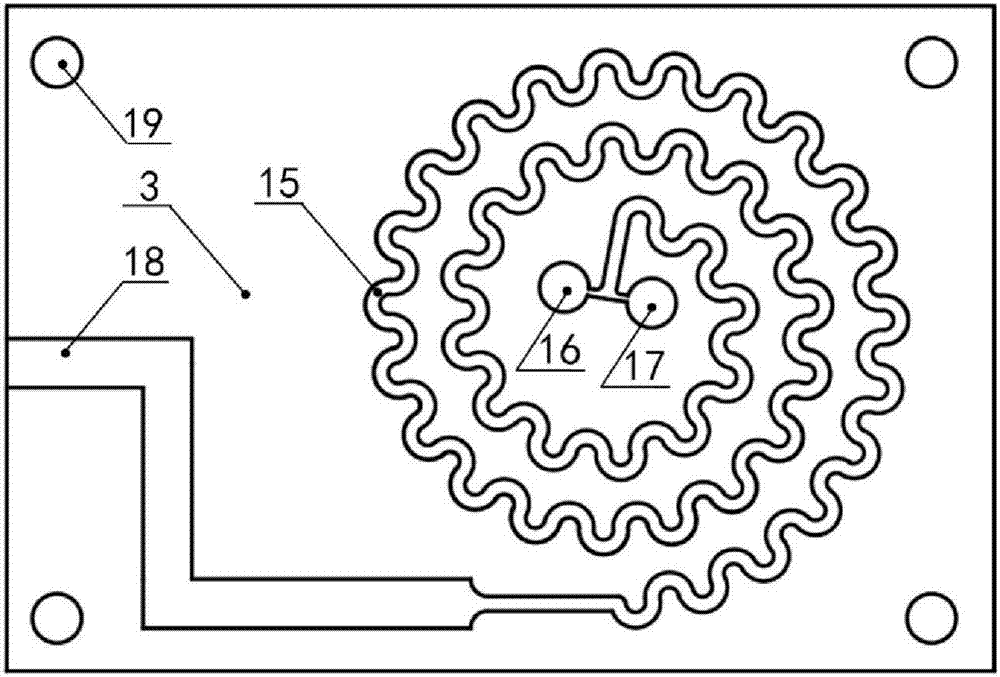

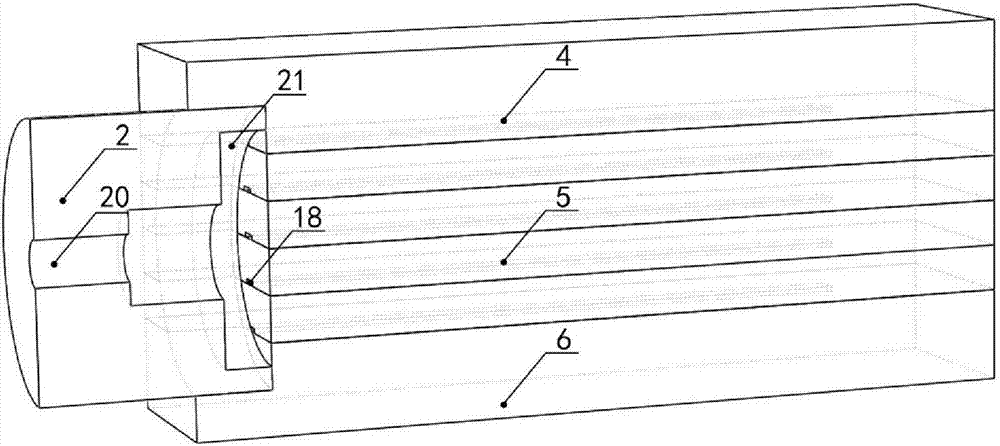

[0046] When the circulating high-throughput microparticle sorting and concentration device of the present invention sorts and concentrates the sample, the particle suspension placed in the inner outlet solution collection bottle 8 is introduced into the flow distribution joint 2 through the peristaltic pump 1 at a specific flow rate; The flow distribution joint 2 enters each layer of the multi-layer superimposed microfluidic chip 3 at the same flow rate; the micro-particles 22 in the particle suspension will be subjected to the fluid drag force F in the chip 1 due to the parabolic velocity profile23 of the Boxiao lobe flow in the flow channel, the microparticles will be subjected to shear-induced inertial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com