Upper table board

A table and support table technology, applied in the field of upper table, can solve the problems of accurate positioning of the workpiece, no consideration of workpiece clamping, and inability to guarantee the accuracy of processing, etc., to reduce the generation of defective products and improve the structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

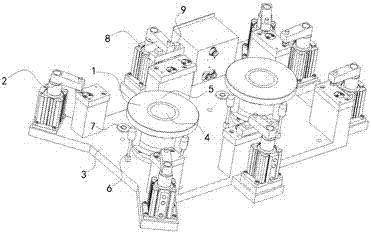

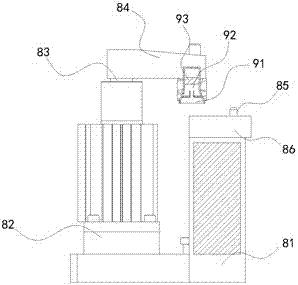

[0026] Such as figure 1 , figure 2 with image 3 The shown upper table has a base 3 on which a support unit 1 and a fixed unit 2 are fixed. The fixed unit 2 has two arranged left and right, and five evenly arranged around each fixed unit The support table unit 1, wherein the front and rear fixed table units 2 between the two fixed table units 2 are shared by the two fixed table units 2.

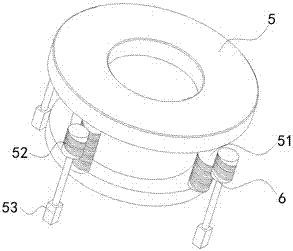

[0027] The support platform unit 1 has a pillar 4 fixed on the base 3, the support platform 5 is sleeved on the pillar 4, the support platform 5 has four adjustment units 6, and the adjustment unit 6 has a connection between the upper and lower sides of the support platform 5 The strut 51 has an adjusting rod 52, and the adjusting rod 52 has a motor 53 arranged on the base 3; the strut 51 is threadedly connected with the adjusting rod 52. The support platform 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com