Flexible substrate lamp tube adhesion facility

A soft substrate and lamp technology, applied in lighting and heating equipment, light sources, lighting devices, etc., can solve problems such as low processing efficiency, reduced production efficiency, and large requirements for driving components, so as to improve overall efficiency, improve work efficiency, The effect of reducing the drive burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

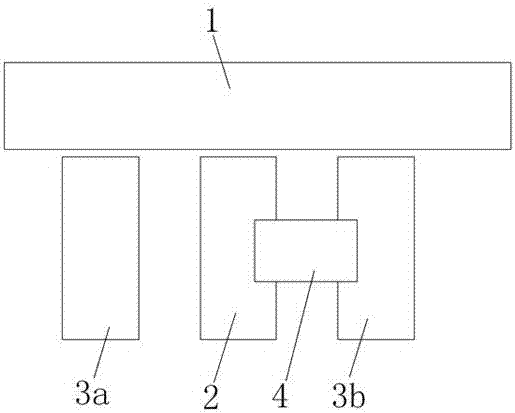

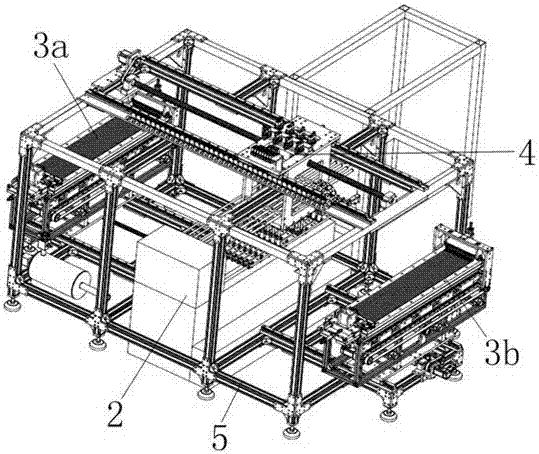

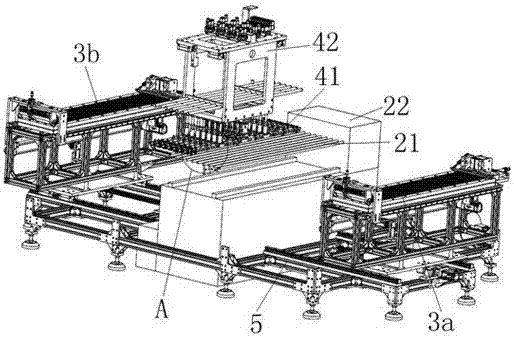

[0042] See attached figure 1 to attach Figure 11 , the invention discloses a flexible substrate lamp tube sticking equipment, including a lamp tube conveying line 1, a glue dispenser 2, a first slitting machine 3a, a second slitting machine 3b, and a light bar transfer mechanism 4. Each structure is described in detail below.

[0043] Wherein the lamp tube conveying line 1 is used for conveying lamp tubes. The input end of the lamp tube conveying line 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com