A 3D printing device and method for a tissue engineering scaffold

A technology of tissue engineering scaffold and 3D printing, which is applied in additive processing, medical science, prosthesis, etc., can solve the problems that it is difficult to realize multiple or even all tissue combination complex structure scaffolds, simple structure and single shape of the scaffold, and achieve mechanical The effect of excellent strength, reasonable structure and composition, and strong manufacturing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary, and is not intended to limit the scope of the present invention and its application.

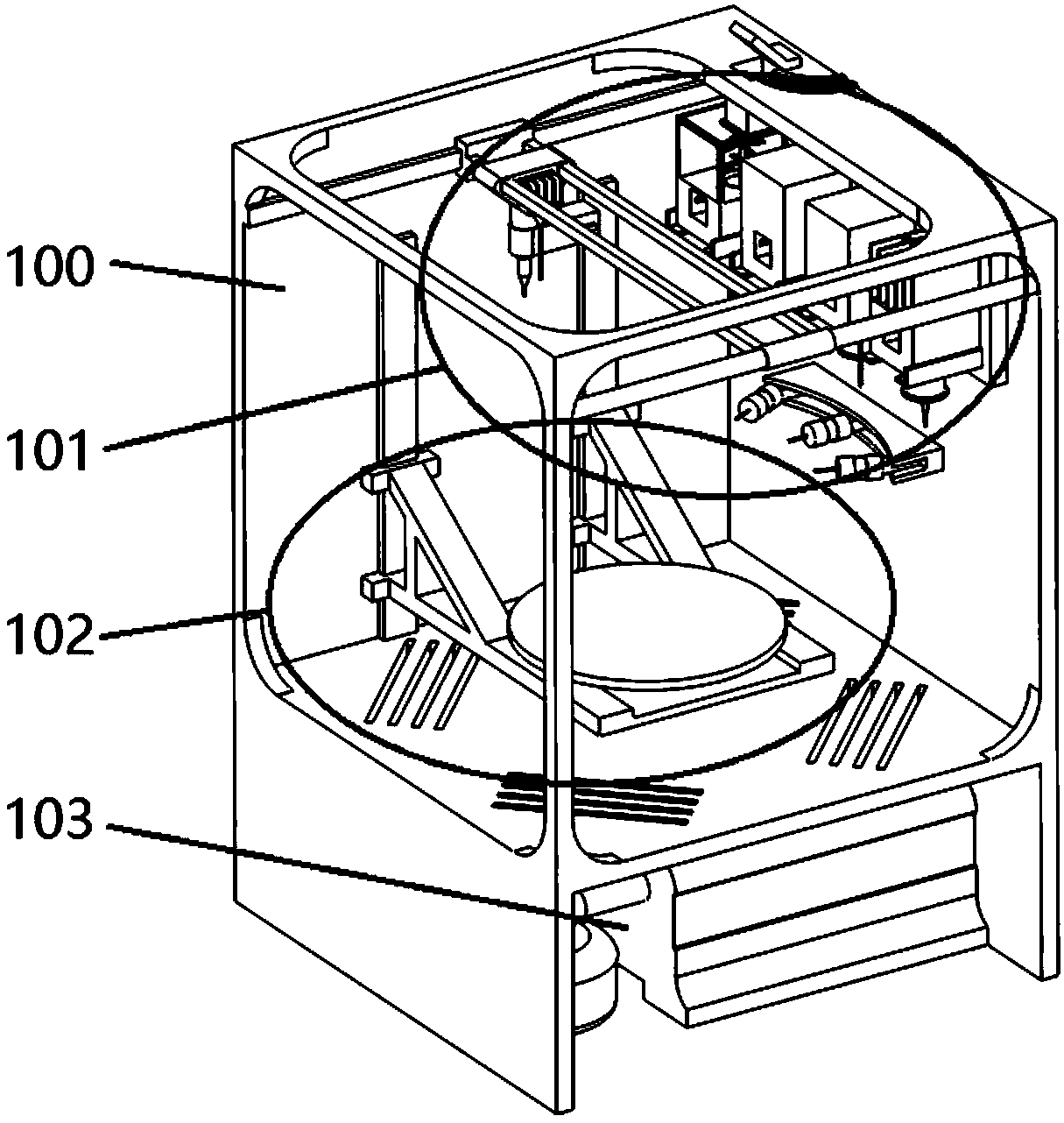

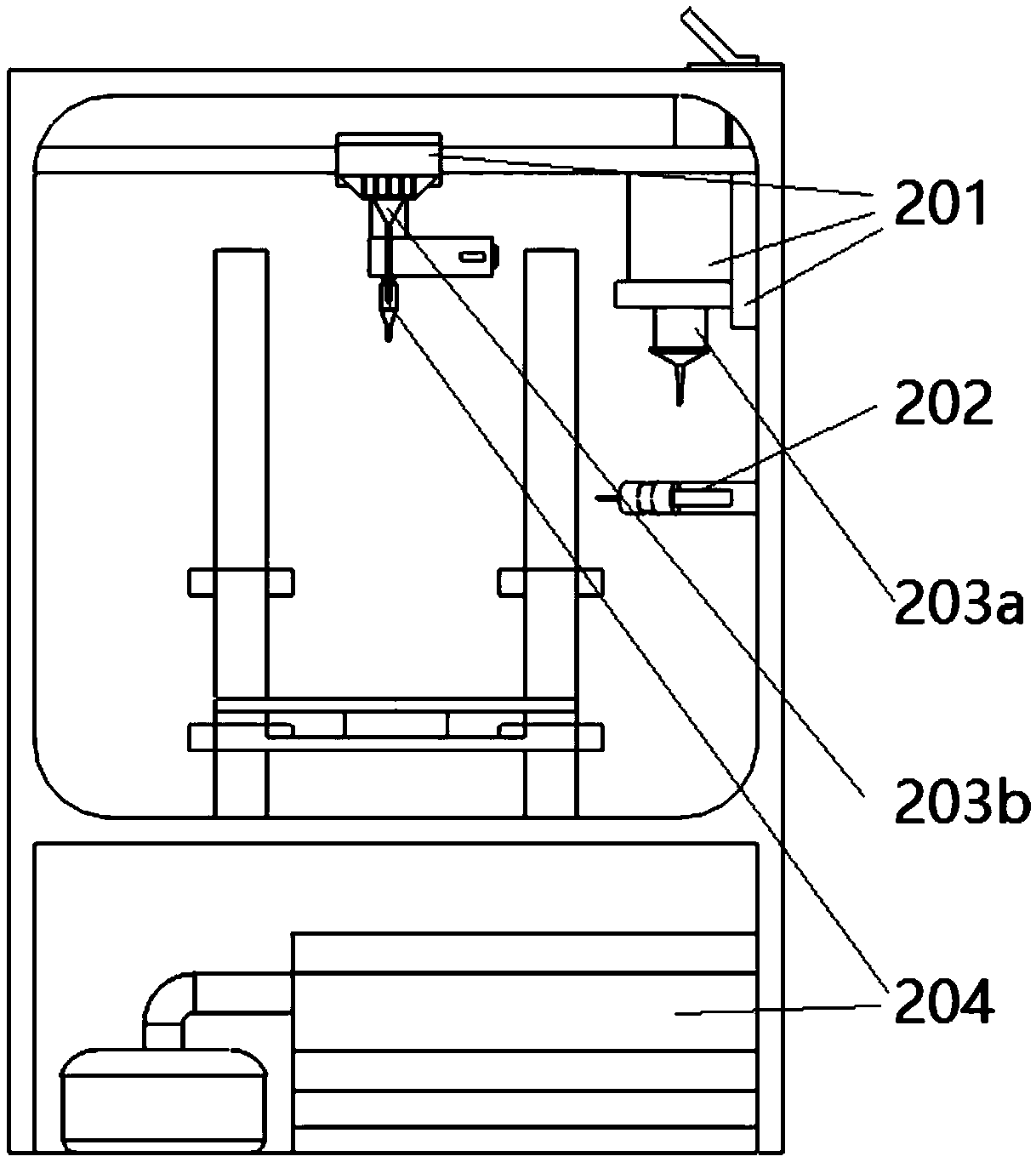

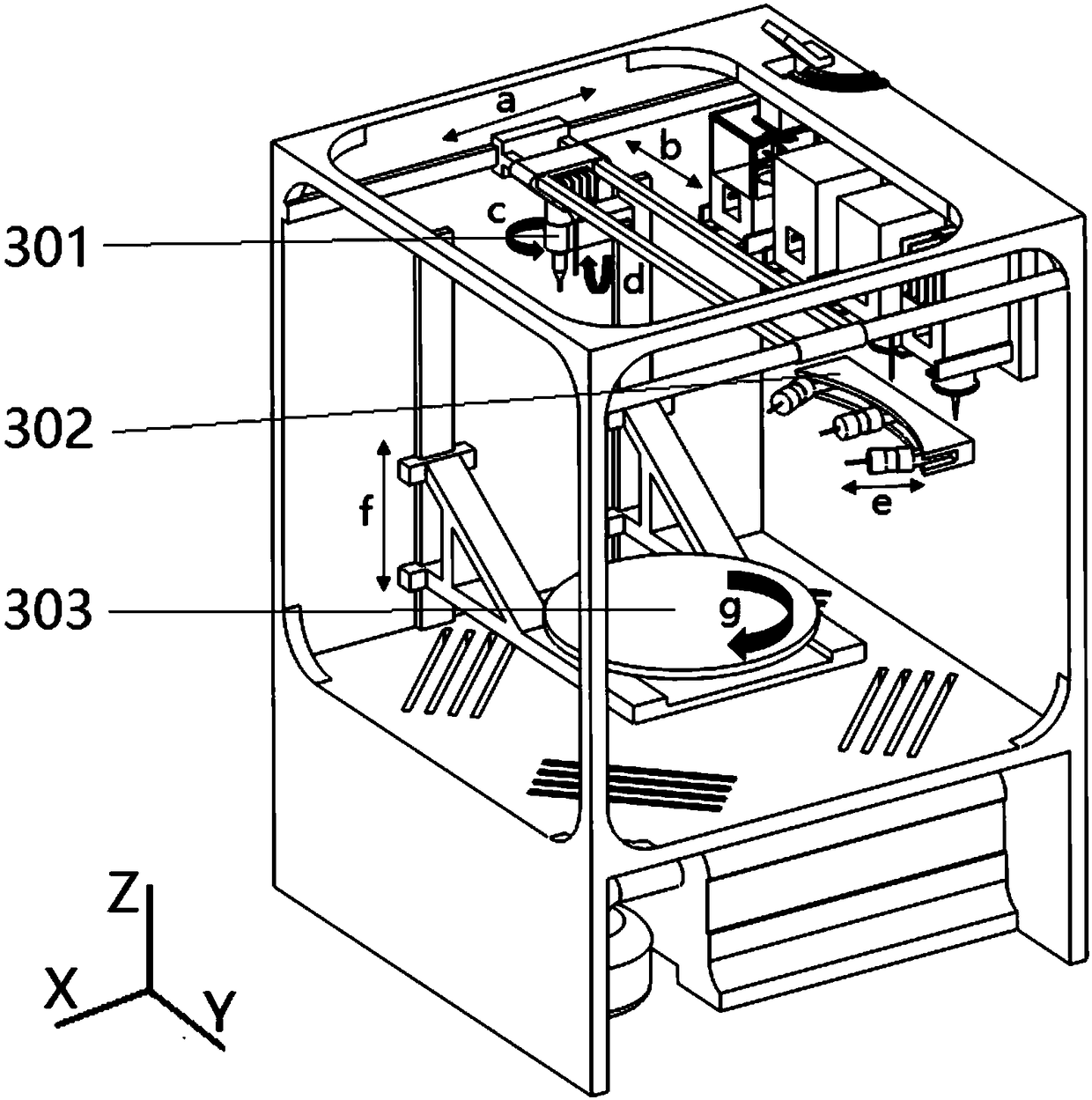

[0033] See Figure 1 to Figure 8 In one embodiment, a 3D printing device for a tissue engineering scaffold includes a printing module 201, a spraying module 202, cell implantation modules 203a, 203b, a printing platform 303, and a temperature control module; the printing module 201 has The extrusion printing device with one or more nozzle devices 403 is used for extrusion printing and forming a tissue engineering scaffold with a three-dimensional macrostructure; the spraying module 202 is a spraying device with one or more nozzles for forming a two-dimensional A tissue engineering scaffold with a macroscopic structure; the cell implantation modules 203a, 203b are inkjet printing devices with one or more nozzles, which are used to eject mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com