Isometric, continuous and repeated shearing type metal forming method and device

An equal-volume, metal technology, applied in the field of volume continuous and repeated shearing forming methods and devices, can solve the problems of complex equipment, difficult forming block blanks, difficult production, etc., achieve grain refinement, control structure, and improve plastic deformation Ability, easy to use and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

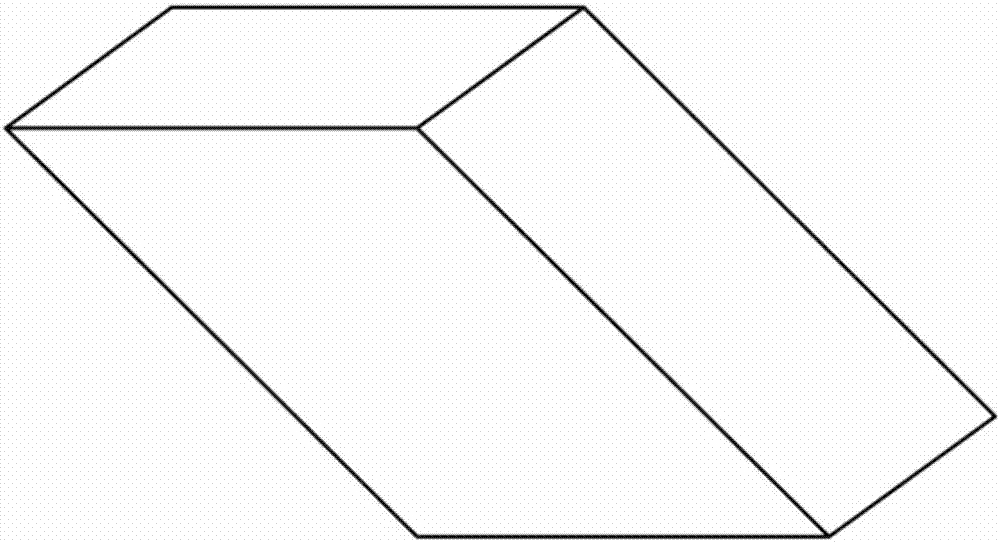

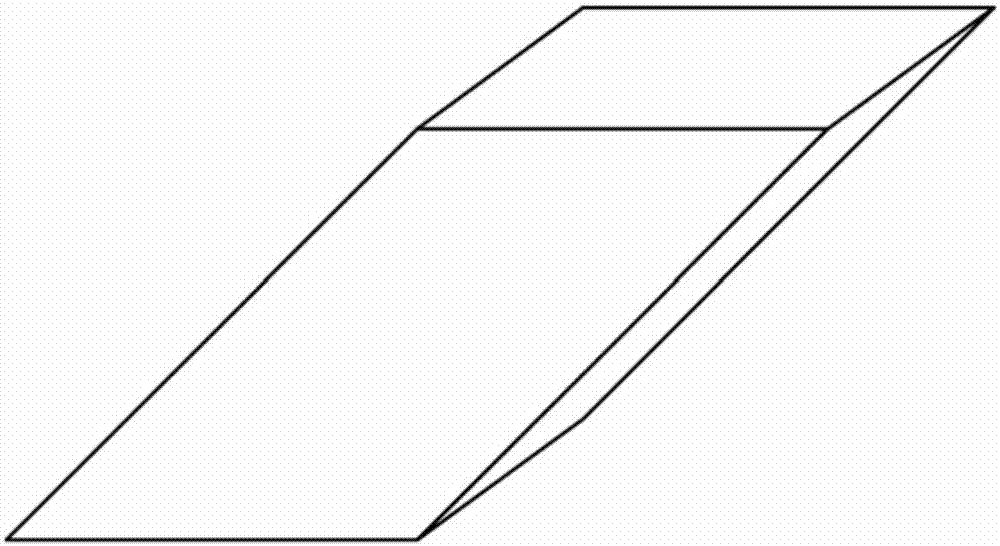

[0034] Such as image 3 As shown, the metal equal volume continuous and repeated shear forming device of the present invention consists of opening and closing plates 1 ( Figure 4 ), base 2, lower rotating plate 3, connecting block 4, top plate 5 ( Figure 5 ), the upper rotating plate 6 ( Figure 6 ), connecting rod 7, fork rod 8, fixed plate 9, spacer bolt 10 ( Figure 7 ), heating device 11, bottom plate 12 ( Figure 8 ), sliding plate 13 ( Figure 9 ) composed of. One end of the upper rotating plate 6 and the lower rotating plate 3 are respectively hinged with the bottom plate 12, and the two ends of the top plate are respectively hinged with the other end of the upper rotating plate 6 and the lower rotating plate 3 to form a parallelogram cylindrical cross section. structure. The fixed plate 9 and the opening and closing plate 1 are respectively placed at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com