Magnesium-based amorphous/porous titanium double-phase three-dimensional communicated composite material and preparation method thereof

A composite material and porous titanium technology, which is applied in the field of magnesium-based amorphous/porous titanium two-phase three-dimensional connected composite materials and its preparation, can solve problems such as brittle fracture of magnesium-based amorphous alloys, and improve plastic deformation ability and deformation resistance Strong ability, excellent performance and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

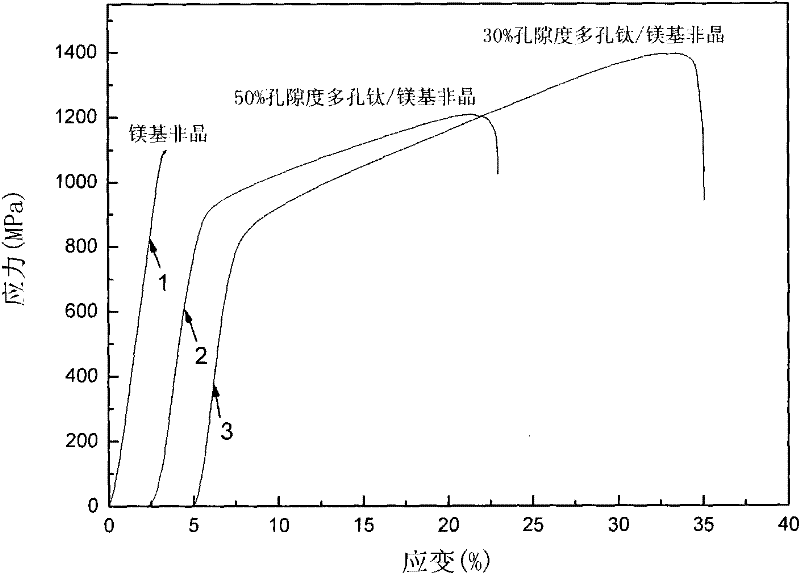

[0047] Mg 63 Cu 16.8 Ag 11.2 Er 9 (at.%) amorphous alloy, its room temperature compression fracture curve is shown in image 3 Curve 1.

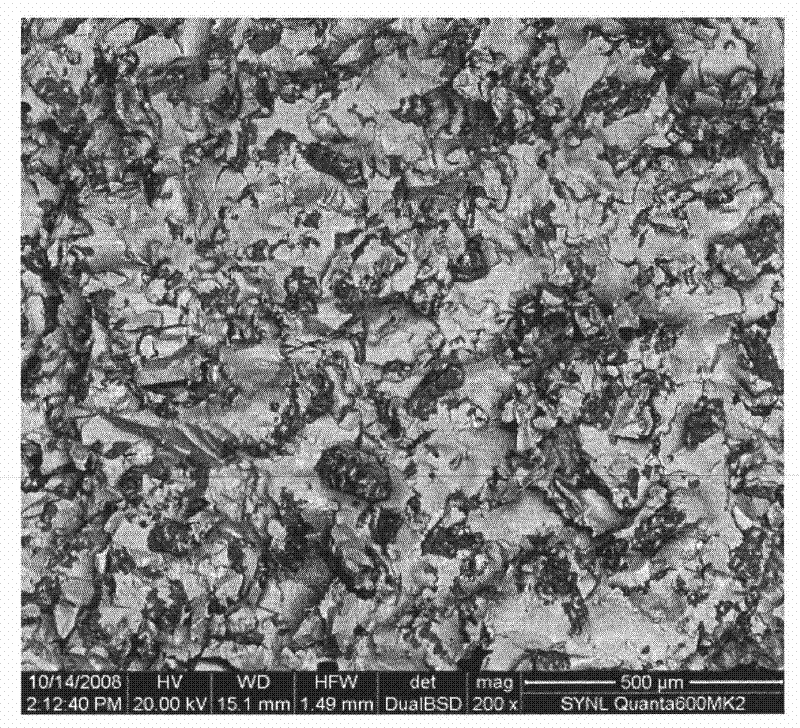

[0048] The size of the room temperature compression test sample is 4mm in diameter, the ratio of height to diameter is 2:1, and the test strain rate is 5×10 -4 the s -1 , and the surface and shear plane of the sample after compression fracture were observed by scanning electron microscope (SEM). The performance indicators are:

[0049] Breaking strength: σ f =1098±20MPa;

[0050] Plastic deformation amount: ε plastic = 0%.

Embodiment 2

[0052] When Mg 63 Cu 16.8 Ag1 1.2 Er 9 (at.%) alloy and 50% porosity porous titanium framework (pore size is 100 ~ 200μm), the room temperature compression fracture curve is shown in image 3 Curve 2.

[0053] The size of the room temperature compression test sample is 4mm in diameter, the ratio of height to diameter is 2:1, and the test strain rate is 5×10 -4 the s -1 , and the surface and shear plane of the sample after compression fracture were observed by scanning electron microscope (SEM). The performance indicators are:

[0054] Breaking strength: σ f =1190±20MPa;

[0055] Plastic deformation amount: ε plastic =19±2%.

Embodiment 3

[0057] When Mg 63 Cu 16.8 Ag 11.2 Er 9 (at.%) alloy and 30% porosity porous titanium framework (pore size is 100 ~ 200μm), the room temperature compression fracture curve is shown in image 3 Curve 3.

[0058] The size of the room temperature compression test sample is 4mm in diameter, the ratio of height to diameter is 2:1, and the test strain rate is 5×10 -4 the s -1 , and the surface and shear plane of the sample after compression fracture were observed by scanning electron microscope (SEM). The performance indicators are:

[0059] Breaking strength: σ f =1400±15MPa;

[0060] Plastic deformation amount: ε plastic =28±2%.

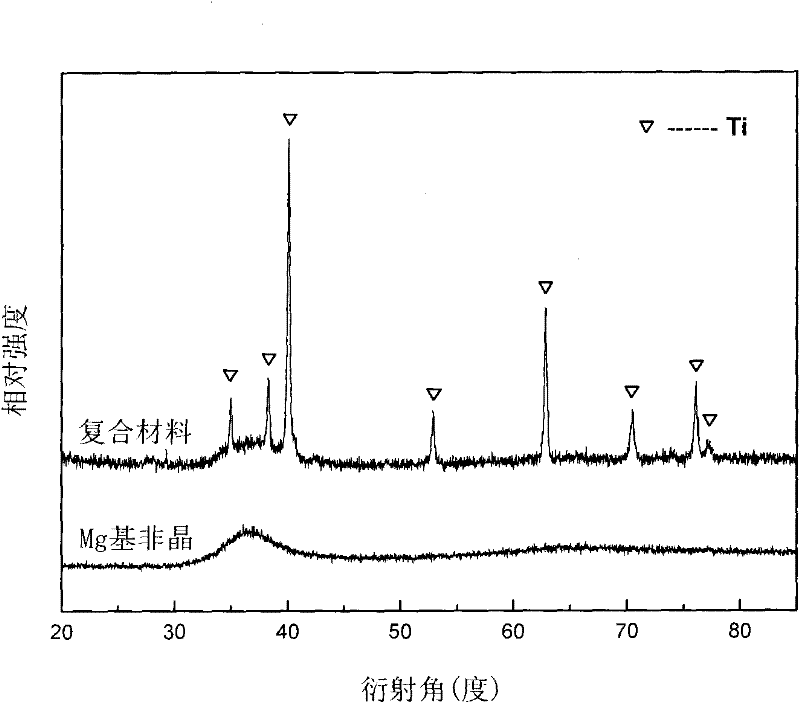

[0061] Such as figure 2 As shown, comparing the X-ray diffraction curves of the magnesium-based amorphous alloy and this embodiment, it can be seen that no chemical reaction occurs after the composite of the magnesium-based amorphous alloy matrix and the porous titanium skeleton, and the amorphous formation ability of the amorphous alloy is no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com