Device and method for preparation of soil body for site soil body direct shear test and direct shear test

A technology for preparing devices and testing devices, which is applied in the preparation of test samples, measuring devices, and the use of stable shear force to test the strength of materials. It can solve the problems of large workload, high time and labor costs, geometric dimensions, Problems such as angle and flatness are not standard, so as to achieve the effect of convenient installation and disassembly, convenient transportation and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

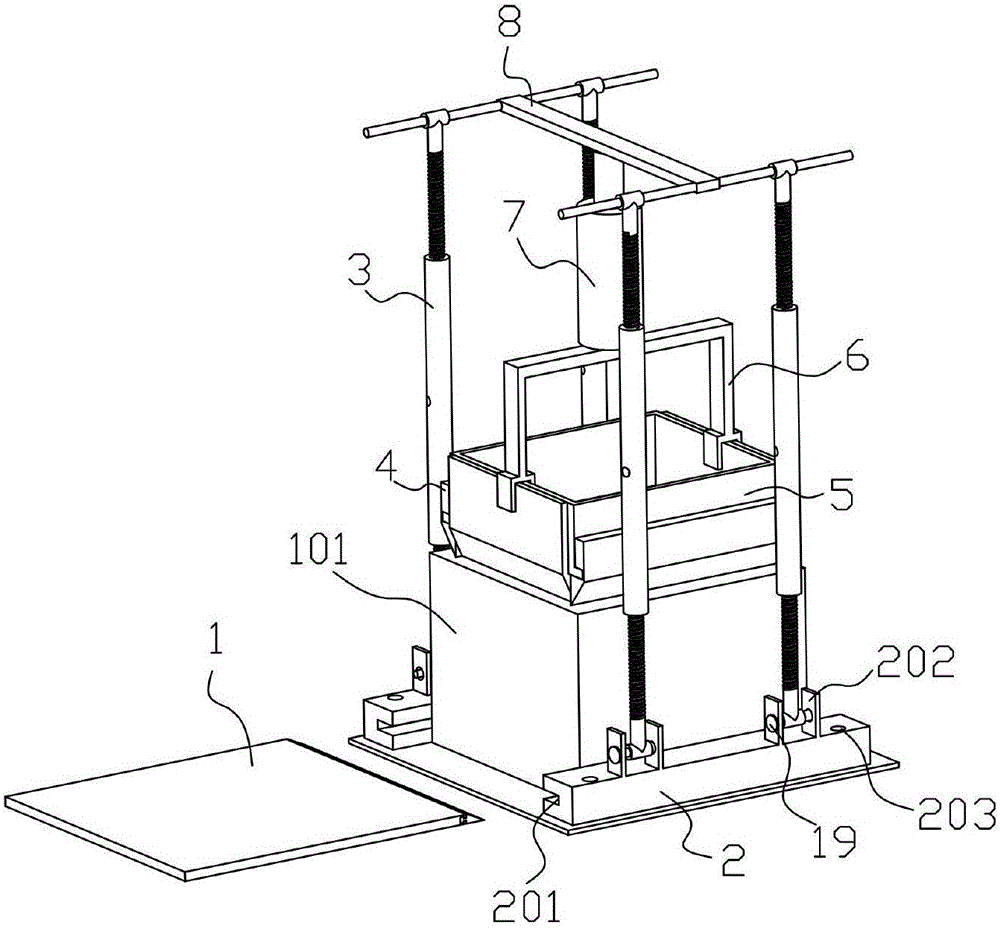

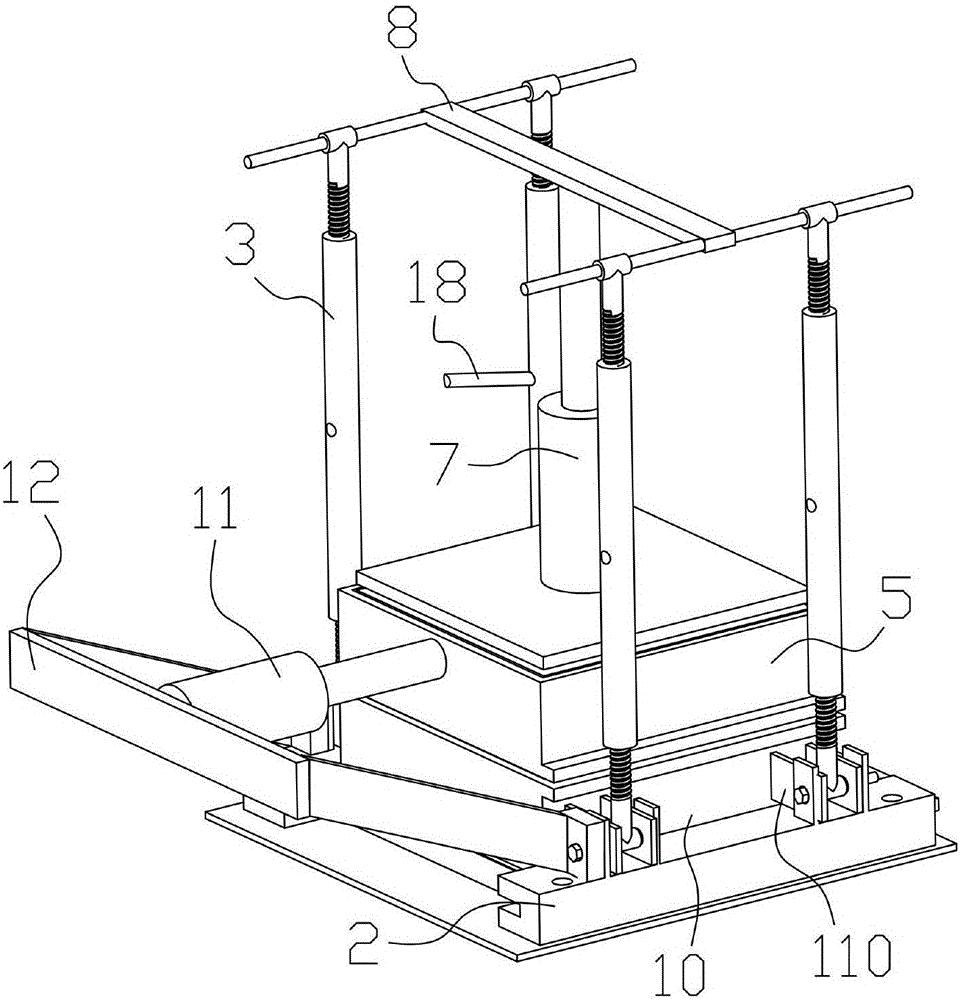

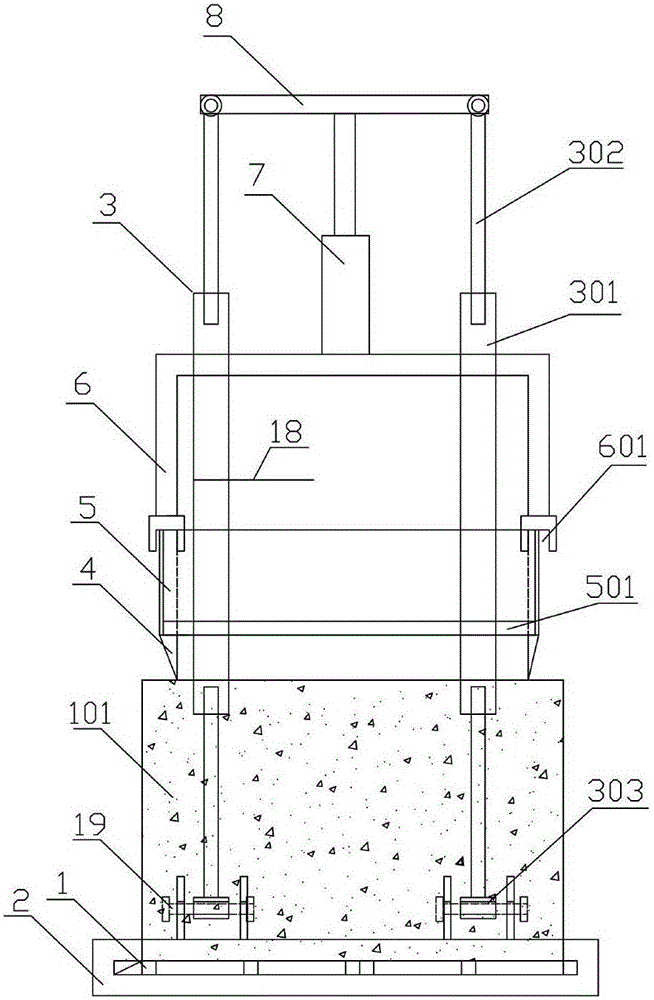

[0050] A soil preparation device for on-site soil direct shear test, comprising preparation components and loading components,

[0051] Preparation assembly: including a bottom frame, a bottom plate 1, a telescopic assembly and an upper cutting box 5, the telescopic assembly is hinged on the bottom frame, the bottom plate 1 is movably installed in the bottom frame, and the upper cutting box 5 is located in the telescopic assembly;

[0052] Loading assembly: including a first jack 7, a force transmission frame 6, a fixed frame 8 fixedly connected to the top of the telescopic assembly, one end of the first jack 7 is fixedly connected to the fixed frame 8, and the other end is against the force transmission On the end face of the frame 6 , the end of the force transmission frame 6 away from the first jack 7 abuts against the upper cutting box 5 .

[0053] Further, the force transmission frame 6 is in an "n" shape, and a clamping slot 601 is respectively fixed at two ends of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com