Vacuum cover for storage container

A storage tank and vacuum technology is applied in the field of vacuum lids for storage tanks, which can solve the problems of inappropriate wide-mouth storage tanks and damage to storage tanks, and achieve the effects of storage function guarantee and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

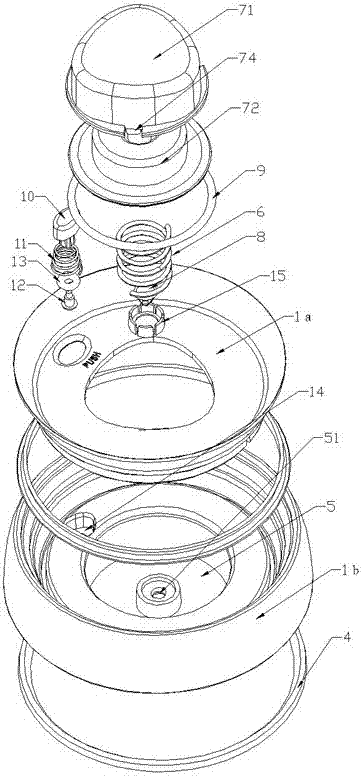

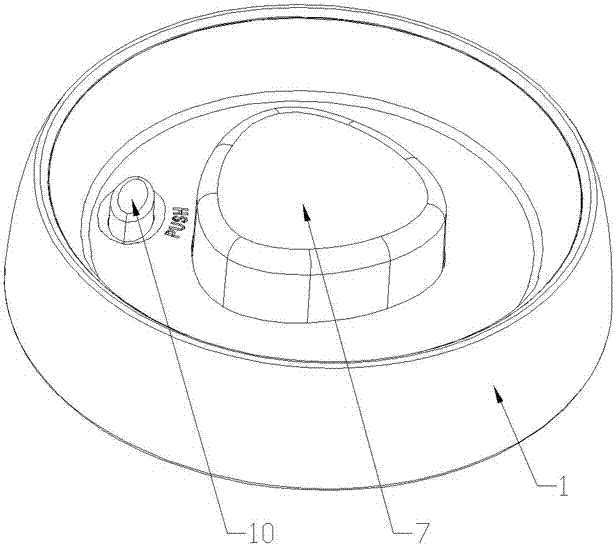

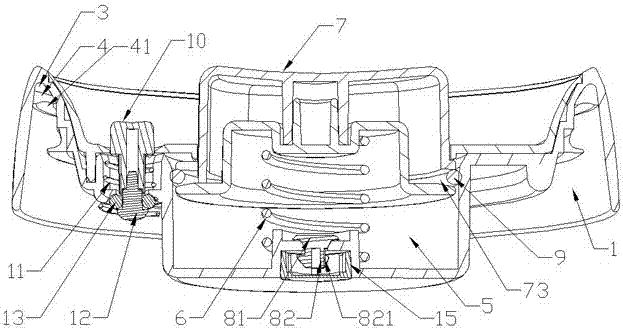

[0022] like Figure 1 to Figure 6As shown, the present invention includes a cover body 1. In this embodiment, the cover body 1 is composed of a surface cover 1a and an outer cover 1b, and the surface cover 1a and the outer cover 1b are combined into one. On the lower side of the cover 1 and near the edge, there is a groove 3 that is suitable for the mouth of the storage tank 2, and a first sealing ring 4 is arranged in the groove 3. A concave groove 41 matching the mouth of the storage tank 2 is provided on the lower side of the first sealing ring 4 . A chamber 5 is also provided on the cover body 1, and a vacuum pressing block 7 is matched with a first return spring 6 on the chamber 5, and the edge of the vacuum pressing block 7 is in contact with the chamber 5. There is a sliding and sealing fit between the inner walls of the inner walls, and food-grade lubricants are filled in the joints. The addition of the food-grade lubricants is to make the sliding fit between the edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com