Grabbing and moving conveying frame for carrying cloth reel

A cloth reel, mobile conveying technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as troubles, achieve good results and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

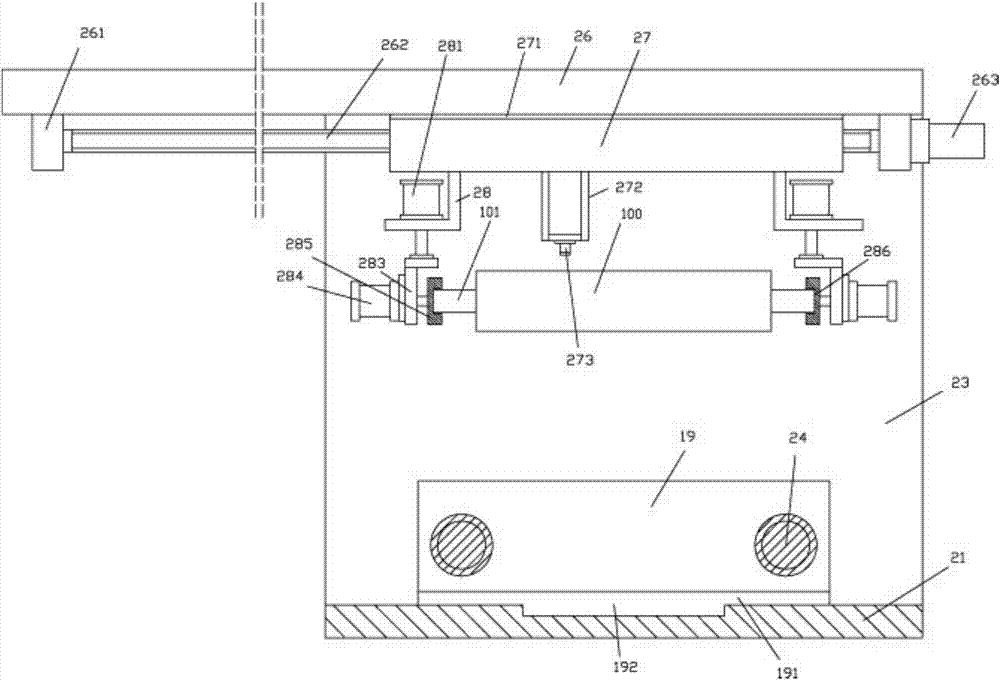

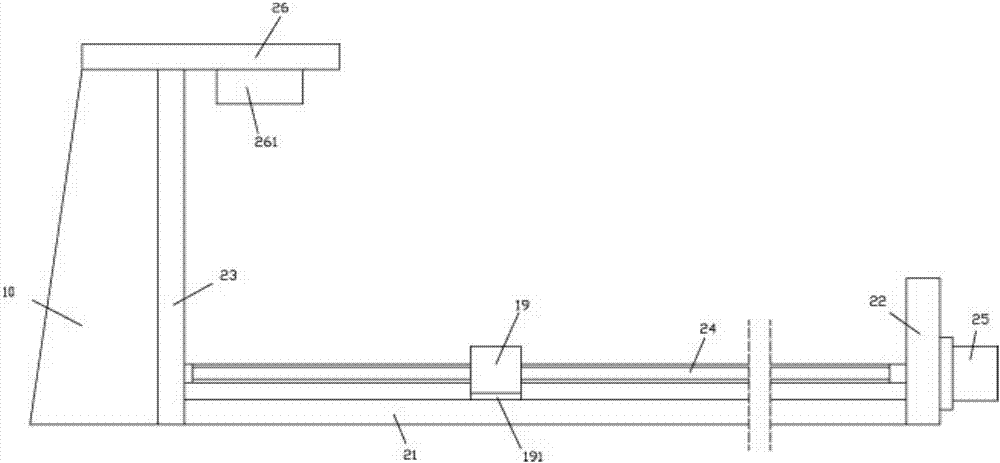

[0020] Examples, see e.g. Figure 1 to Figure 2 As shown, a kind of cloth reel handling is used grabbing and moving conveying rack, and it comprises bottom plate 21, and one end of bottom plate 21 is fixed with vertical support plate 22, and the other end of bottom plate 21 is fixed with grabbing connecting plate 23, and transmission The two ends of screw rod 24 are hinged on vertical support plate 22 and grab connection plate 23, and the outer sidewall of vertical support plate 22 is fixed with mobile motor 25, and the output shaft of mobile motor 25 is spline shaft, and spline shaft inserts Set in the spline hole provided at one end of the transmission screw 24, the moving block 19 is screwed in the transmission screw 24, the bottom surface of the moving block 19 is fixed with a self-lubricating layer 191, and the self-lubricating layer 191 is pressed against the top surface of the bottom plate 21 superior;

[0021] The top of the grasping connecting plate 23 is fixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com