Conveyance frame for hollow glass transferring

A glass transfer and transport frame technology, applied in the direction of transport and packaging, conveyor objects, furnaces, etc., can solve the problems of inconvenient handling, inconvenient installation and disassembly of transport racks, inconvenient glass processing and utilization, etc., to achieve easy handling, easy handling and Assembling and improving the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

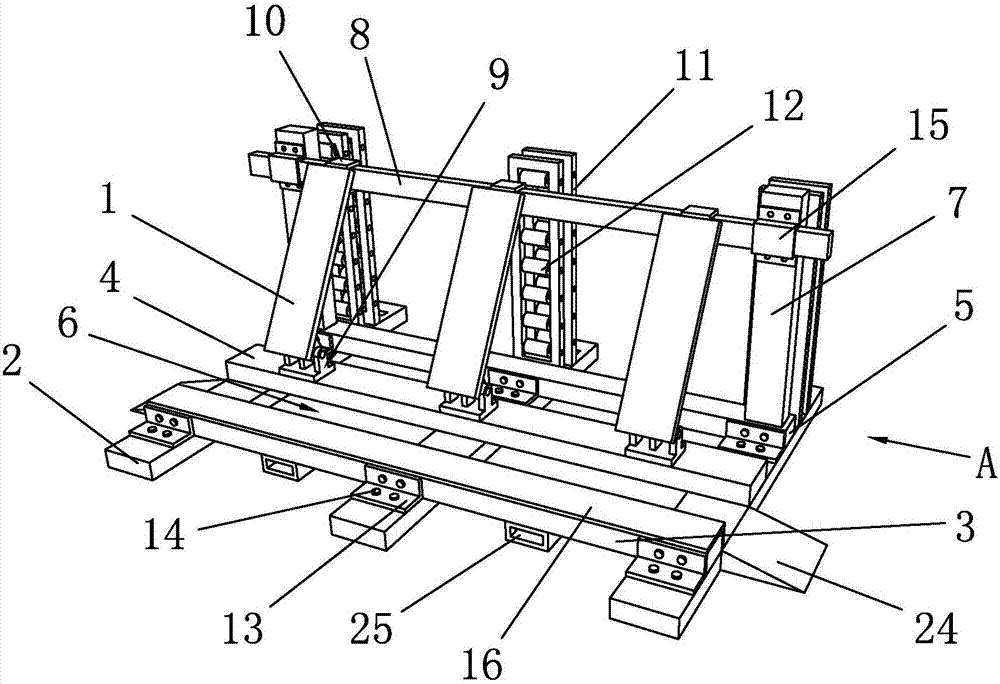

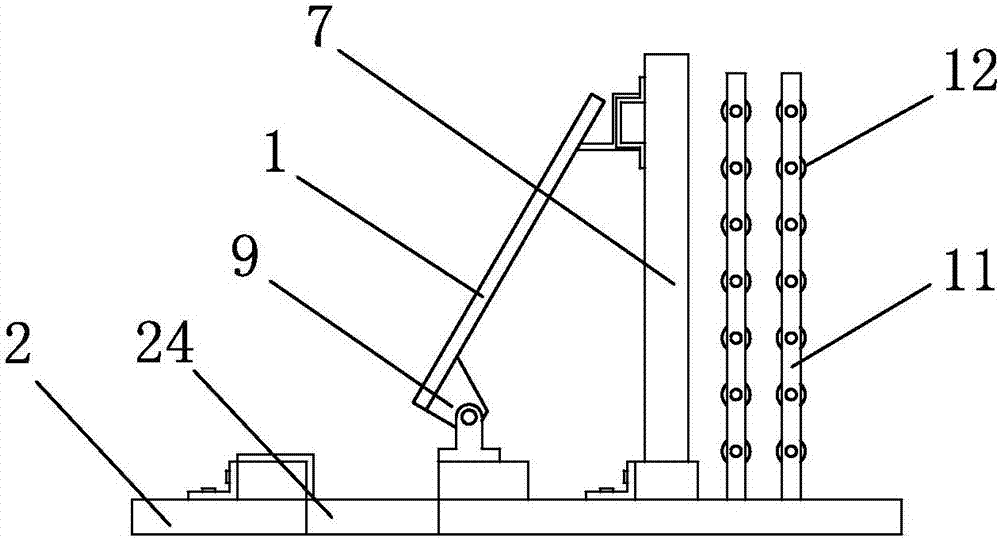

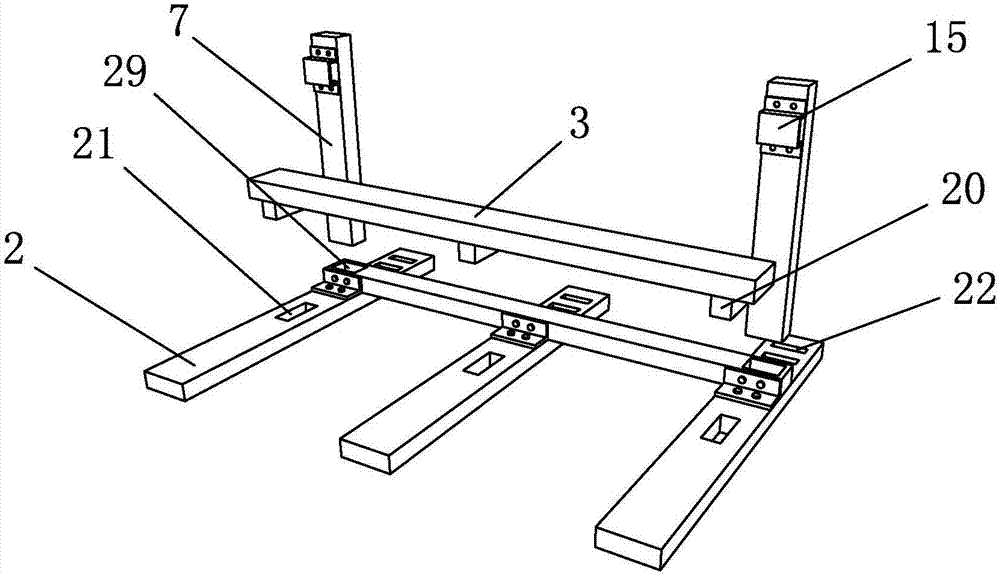

[0026] Such as Figure 1 to Figure 5 As shown, it is a transportation frame for hollow glass transfer of the present invention, including a frame body and a glass support plate 1, the frame body includes a transverse strut 2 and a horizontal strut, and the transverse strut 2 is evenly provided with embedding grooves 22. An inlay block 23 is arranged under the glass limiting frame 11, and the inlay block 23 matches the inlay groove 22, and the inlay block 23 is embedded in the inlay groove 22 to clamp the glass limiting frame 11 and the transverse strut 2 The design of the inlay groove 22 and the inlay block 23 can facilitate the limit and fixation between the glass limit frame 11 and the transverse strut 2, simplify the installation operation steps, and the horizontal struts are evenly arranged on the horizontal struts 2. Above, the horizontal strut includes a limit strut 3, a first fixed strut 4, and a second fixed strut 5 arranged in sequence from front to back, and a flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com