Enterococcus faecalis high-density fermentation medium and its fermentation process

A technology of high-density fermentation and fermentation medium, which is applied to the high-density fermentation production of Enterococcus faecalis, the high-density fermentation medium of Enterococcus faecalis and its fermentation technology field, which can solve the problem of low fermentation level, increased cost and low number of viable bacteria. and other problems, to achieve the effect of reducing separation costs, improving production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

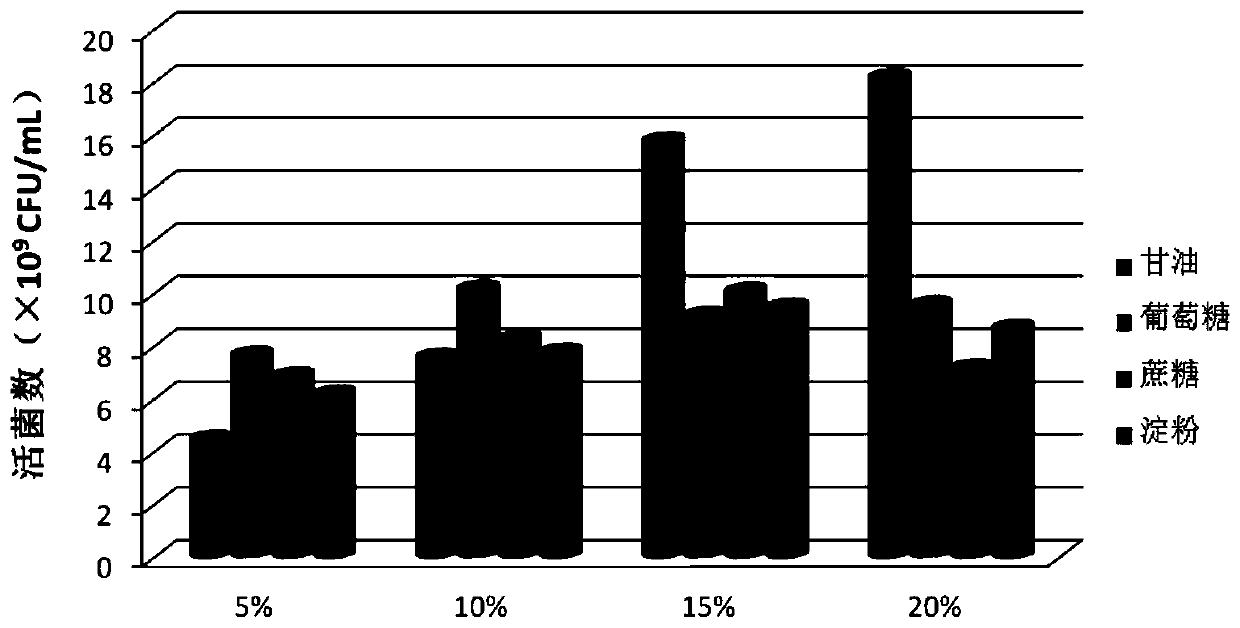

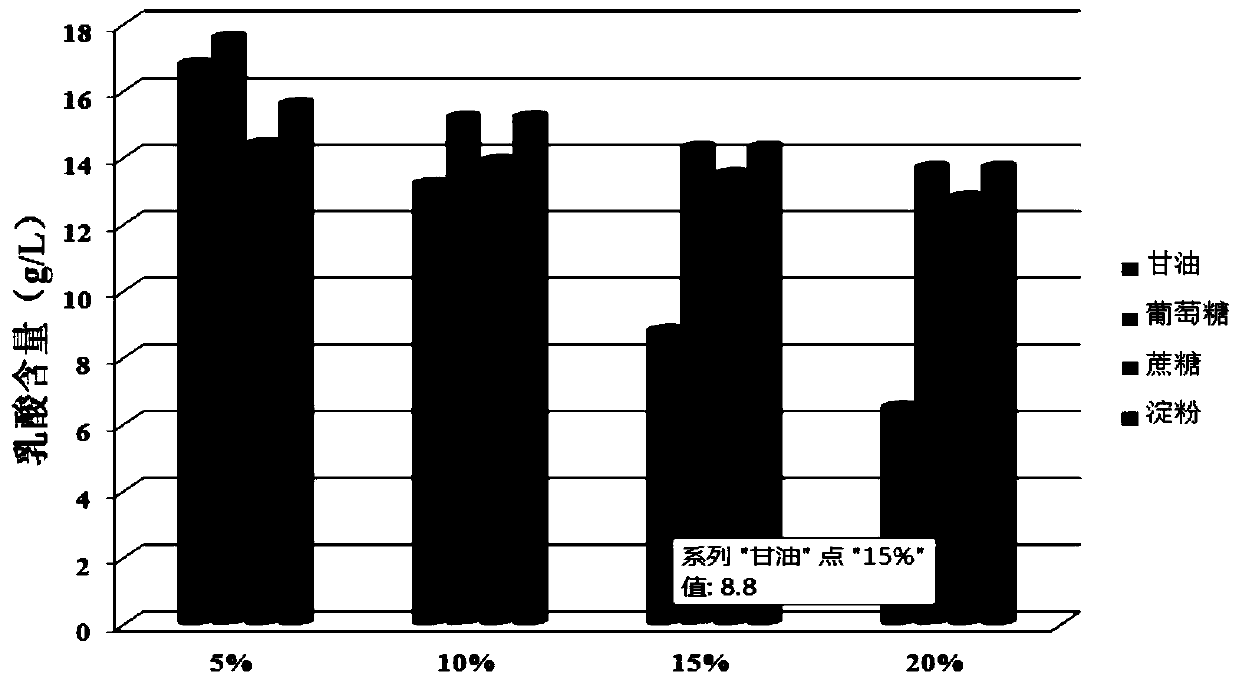

[0030] Example 1 Utilizing different carbon sources to carry out high-density fermentation of Enterococcus faecalis

[0031] Fermentation medium: soybean meal 10g / L, ammonium sulfate 2g / L, dipotassium hydrogen phosphate trihydrate 2g / L, sodium acetate trihydrate 5g / L, sodium citrate dihydrate 2g / L, magnesium sulfate heptahydrate 0.3g / L , manganese sulfate monohydrate 0.2g / L, glycerin / glucose / sucrose / starch 20g / L, adjust to pH 7.0 with 25% ammonia water.

[0032] Seed solution preparation: Streak Enterococcus faecalis glycerol strains stored at -80°C on MRS (glucose 20g / L; peptone 10g / L; yeast powder 5g / L; diammonium hydrogen citrate 2g / L; sodium acetate 5g / L; Dipotassium Hydrogen Phosphate 2g / L; Magnesium Sulfate 0.58g / L; Manganese Sulfate 0.25g / L) on the agar medium, place in a 32°C incubator and cultivate until a single colony grows; pick a full single colony to inoculate Put into MRS liquid test tube, 37°C, 50r / min shaking flask culture for 10 hours; transfer to MRS liqui...

Embodiment 2

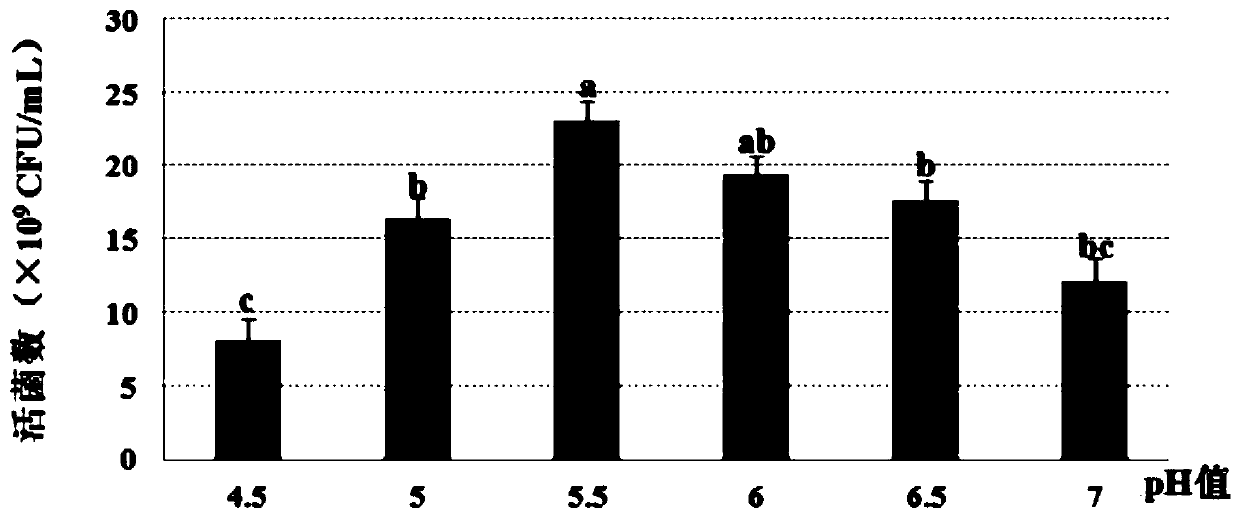

[0035] Embodiment 2 controls the impact of different pH on high-density fermentation of Enterococcus faecalis

[0036]Fermentation medium: soybean meal 15g / L, glycerin 25g / L, ammonium sulfate 2g / L, dipotassium hydrogen phosphate trihydrate 3g / L, sodium acetate trihydrate 5g / L, sodium citrate dihydrate 3g / L, sulfuric acid heptahydrate Magnesium 0.5g / L, manganese sulfate monohydrate 0.25g / L.

[0037] Seed solution preparation: Streak Enterococcus faecalis glycerol strains stored at -80°C on MRS (glucose 20g / L; peptone 10g / L; yeast powder 5g / L; diammonium hydrogen citrate 2g / L; sodium acetate 5g / L; Dipotassium Hydrogen Phosphate 2g / L; Magnesium Sulfate 0.58g / L; Manganese Sulfate 0.25g / L) on the agar medium, place in a 33°C incubator and cultivate until a single colony grows; pick a full single colony to inoculate Put into MRS liquid test tube, 32°C, 150r / min shaking flask culture for 10 hours; transfer to MRS liquid medium with 1% inoculum amount, 37°C, 100r / min shaking culture...

Embodiment 3

[0040] The optimization of embodiment 3 most suitable alkaline pH neutralizer

[0041] Fermentation medium: soybean meal 10g / L, glycerin 20g / L, ammonium sulfate 1g / L, dipotassium hydrogen phosphate trihydrate 2g / L, sodium acetate trihydrate 8g / L, sodium citrate dihydrate 2g / L, sulfuric acid heptahydrate Magnesium 0.4g / L, manganese sulfate monohydrate 0.25g / L.

[0042] Seed solution preparation: Streak Enterococcus faecalis glycerol strains stored at -80°C on MRS (glucose 20g / L; peptone 10g / L; yeast powder 5g / L; diammonium hydrogen citrate 2g / L; sodium acetate 5g / L; Dipotassium Hydrogen Phosphate 2g / L; Magnesium Sulfate 0.58g / L; Manganese Sulfate 0.25g / L) on the agar medium, place it in a 34°C incubator and cultivate until a single colony grows; pick a full single colony to inoculate Put into MRS liquid test tube, 39°C, 200r / min shaking flask culture for 10 hours; transfer to MRS liquid medium with 1% inoculation amount, 37°C, 100r / min shaking culture for 10 hours as seed liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com