Transparent plate assembly piece

A technology of transparent plates and assemblies, applied in the direction of parallel glass structures, etc., can solve the problems of increased plate weight, increased plate thickness, and inconvenience in construction, and achieve the effects of simplifying technical difficulty, ensuring product quality, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

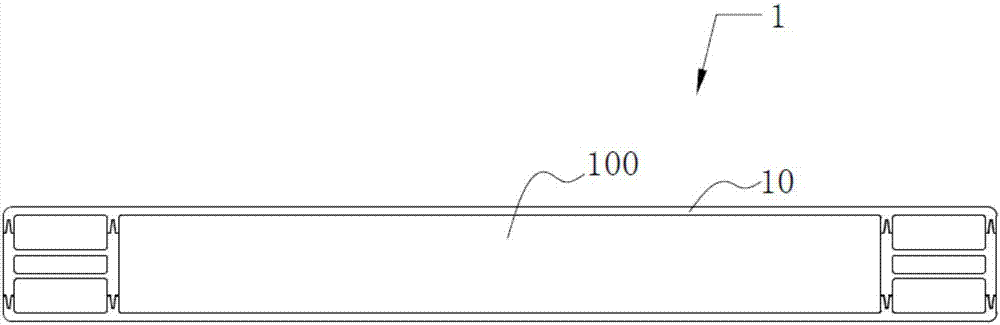

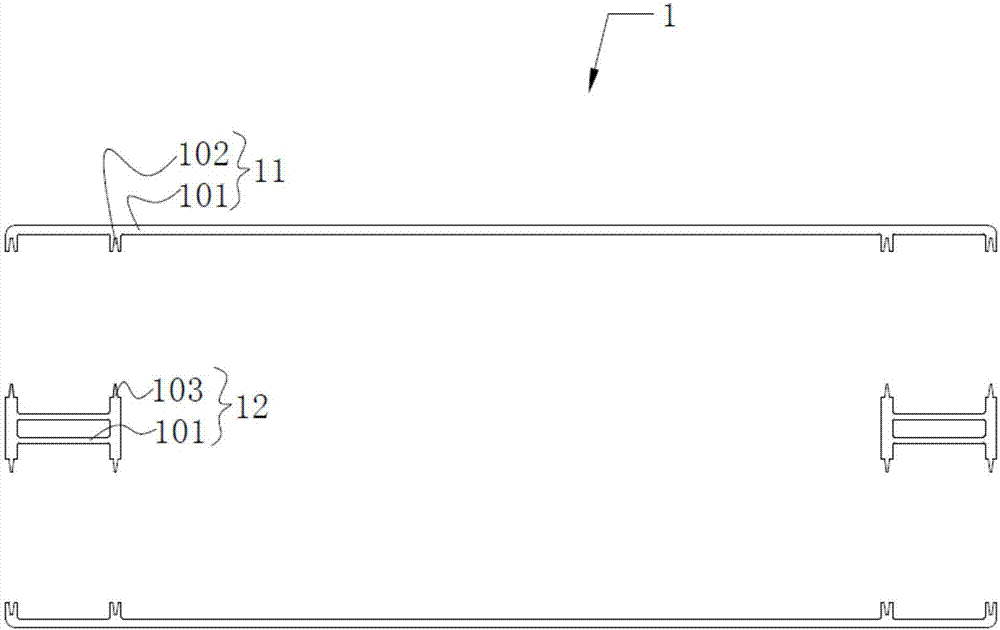

[0045] Please also refer to figure 1 and figure 2 , the assembled composite panel 1 includes a composite panel body 10 , and a plurality of cavities 100 are formed on the composite panel body 10 . The composite board body 10 includes a plurality of transparent board assemblies, and the transparent board assembly includes a transparent board body 101, and the transparent board body 101 is provided with ribs in a direction perpendicular to the board surface. Multiple transparent plate assemblies are connected between ribs or ribs are connected to the transparent plate body 101 to form the composite plate body 10 . The cavity 100 is enclosed by the transparent plate body 101 and the ribs.

[0046] The ribs include concave ribs 102 and convex ribs 103 . The concave rib 102 is a rib with a groove, and the convex rib 103 is a rib with a boss. The concave ribs 102 and the convex ribs 103 cooperate through the fastening of the grooves and the bosses.

[0047] It can be understoo...

Embodiment 2

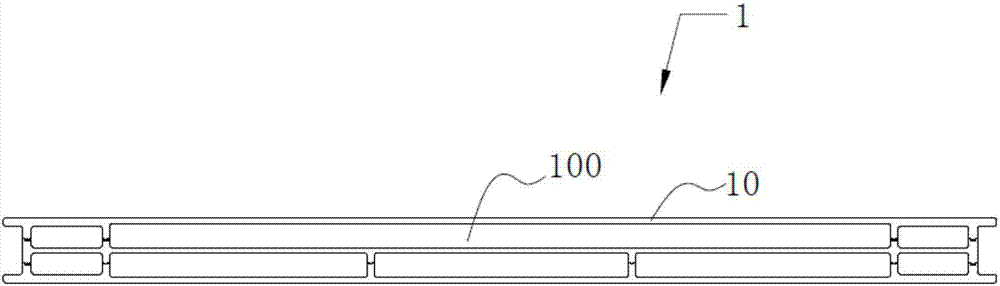

[0063] Please also refer to image 3 and Figure 4 The difference between the assembled composite panel 1 of this embodiment and the first embodiment is that the body of the assembled composite panel 1 of this embodiment includes two panels 11 and a middle partition 13 . Two panels 11 are connected by a middle partition 13 to form a composite panel body 10 .

[0064] The panel 11 is a transparent plate body 101 with convex ribs 103 on one side, and the middle partition 13 is a transparent plate body 101 with concave ribs 102 on both sides. The panel 11 and the middle partition 13 are connected by the fastening of the convex rib 103 and the concave rib 102 , and a hollow cavity 100 is enclosed between the panel 11 and the middle partition 13 .

[0065] Specifically, two protruding ribs 103 are respectively provided at the two ends of a panel 11 . The two ends of the other panel 11 are respectively provided with two ribs 103, and the middle part is provided with two ribs 103 ...

Embodiment 3

[0069] Please also refer to Figure 5 to Figure 7 , the composite panel body 10 of the assembled composite panel 1 in this embodiment includes one panel 11 , six web strips 12 , two intermediate partitions 13 and two transparent panels 101 . One panel 11 is connected to the intermediate partition 13 through two web strips 12 , two intermediate partitions 13 are connected, and one intermediate partition 13 is connected to the panel 11 .

[0070] Specifically, two protruding ribs 103 are provided at the two ends of a panel 11 , and two protruding ribs 103 are provided at the middle. The two ends of another panel 11 are respectively provided with two concave ribs 102, the middle part is provided with two concave ribs 102, and the concave ribs 102 both sides of the middle part are respectively provided with the concave ribs 102 of the end. The two concave ribs 102 are divided into thirds. The transparent body 101 of the panel 11 is relatively long. The web bar 12 is a single-la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com