Air cooling high-temperature dynamic pressure probe

A dynamic pressure and probe technology, applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problem of lack of dynamic pressure testing methods, and achieve the effect of suitable popularization, remarkable effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

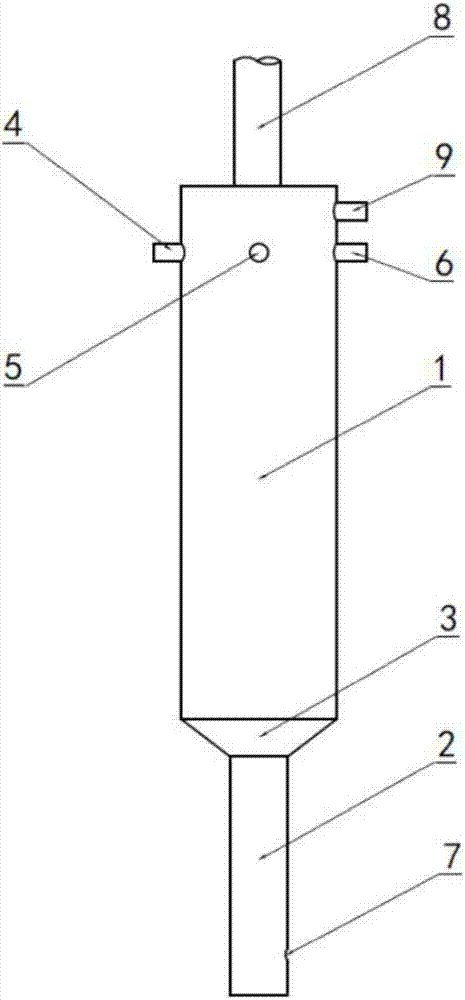

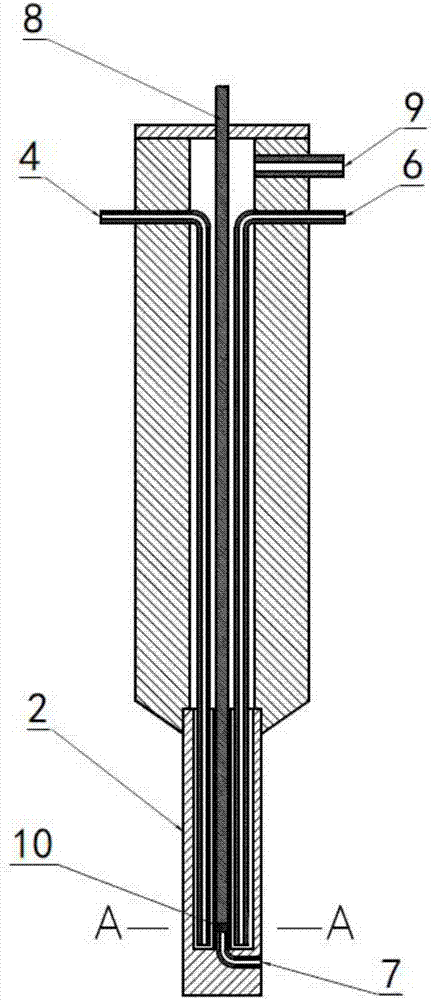

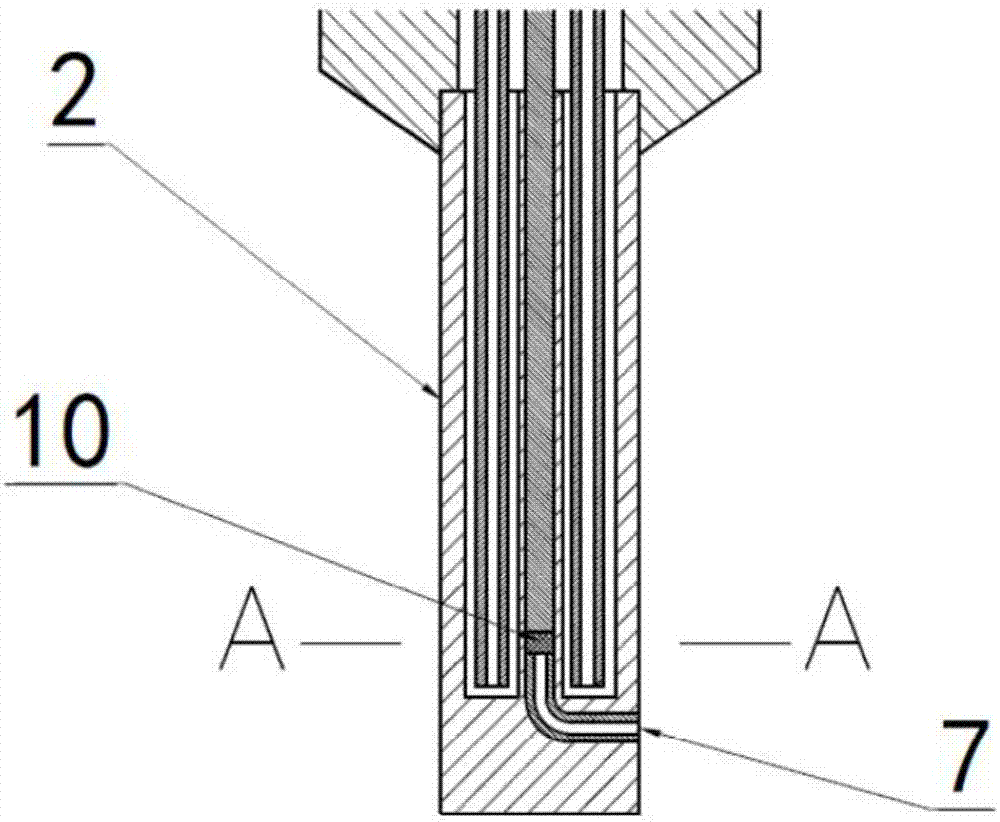

[0022] as attached figure 1 And attached figure 2 As shown, an air-cooled high-temperature dynamic pressure probe is introduced in this embodiment, and the probe includes a probe support rod (1), a probe head (2), and a transition section (3); the probe support rod (1) and the probe head (2) are both cylindrical structures, and the inside of the probe head (2) adopts a special structure; the probe pole is provided with a left air intake pipe (4) and a middle air intake pipe (5) and the right air inlet pipe (6); the three air inlet pipes can carry out the input of cooling gas, and the cooling air inlet pipes (4), (5), and (6) are all inserted into the cylindrical groove of the probe head (2); the probe There is a circular pressure sensing hole (7) on the cylindrical surface of the head (2); the sensor cable (8) leads to the tail of the probe through the inner channel of the probe support rod (1); (1) leads out from the bottom; (10) is a dynamic pressure sensor, followed by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com