Dividing device and dividing method of wafer

A wafer and chip technology, which is applied in the field of segmentation devices, can solve the problems of complex device structure, loose wrinkles, etc., and achieve the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

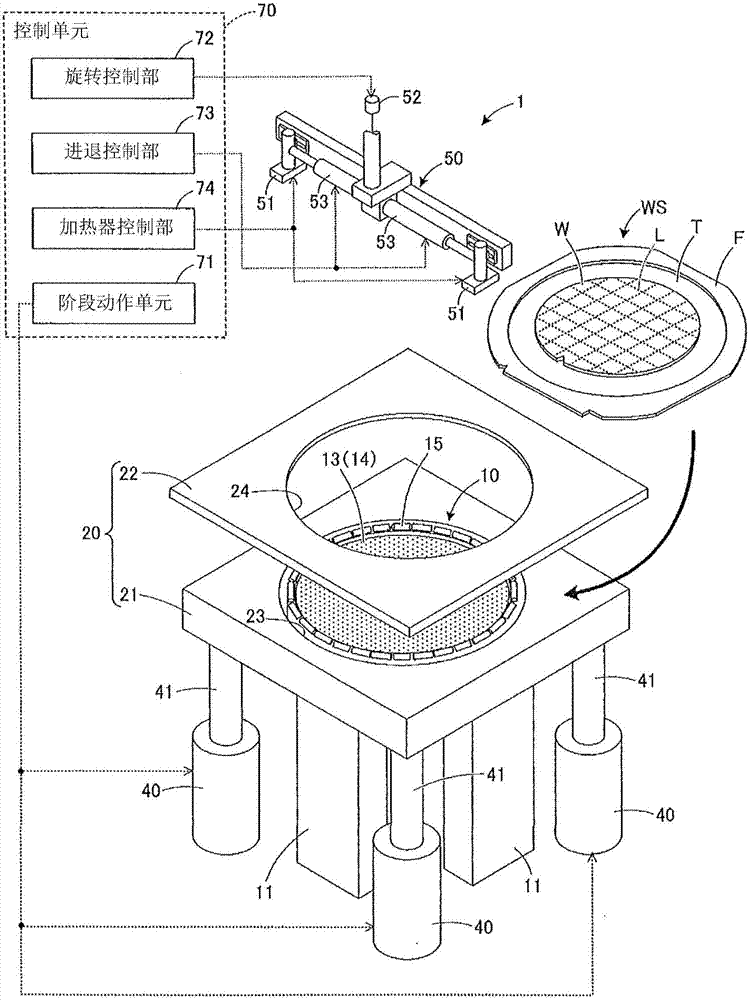

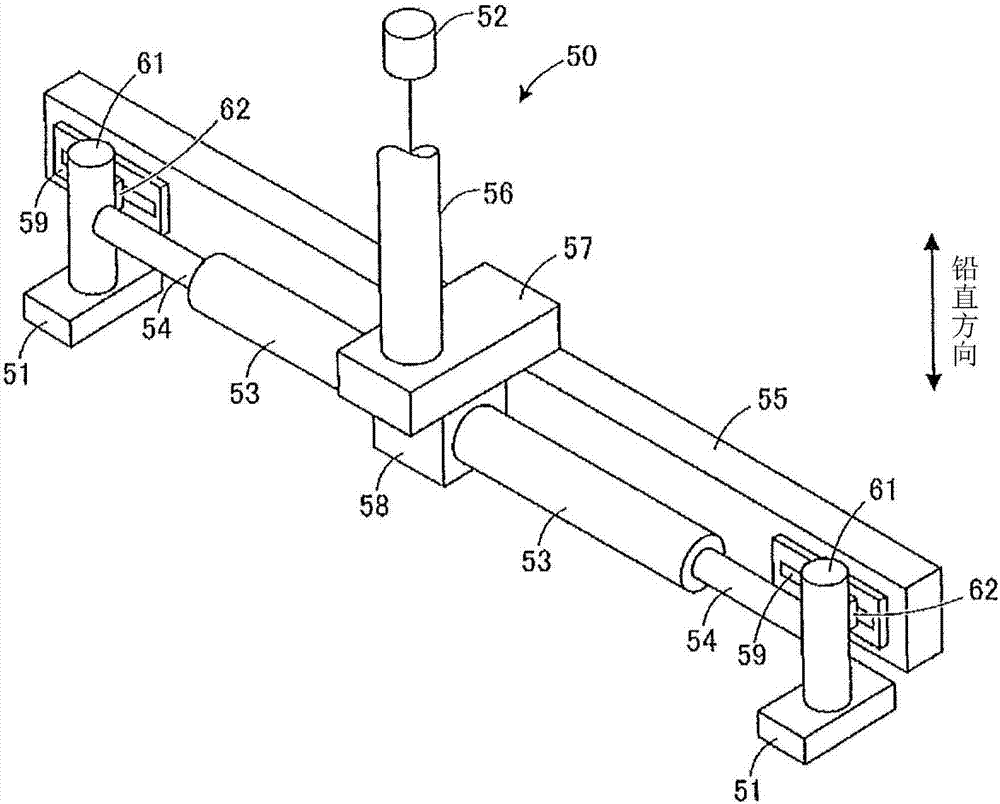

[0029] Hereinafter, a method for dividing a wafer using a dividing device will be described. figure 1 It is a perspective view of the division apparatus of this embodiment. In addition, the dividing device of this embodiment is not limited to figure 1 structure shown. Any structure may be used as long as the splitting device has a structure capable of removing wrinkles of the belt by heating while gradually releasing the expanded state of the belt.

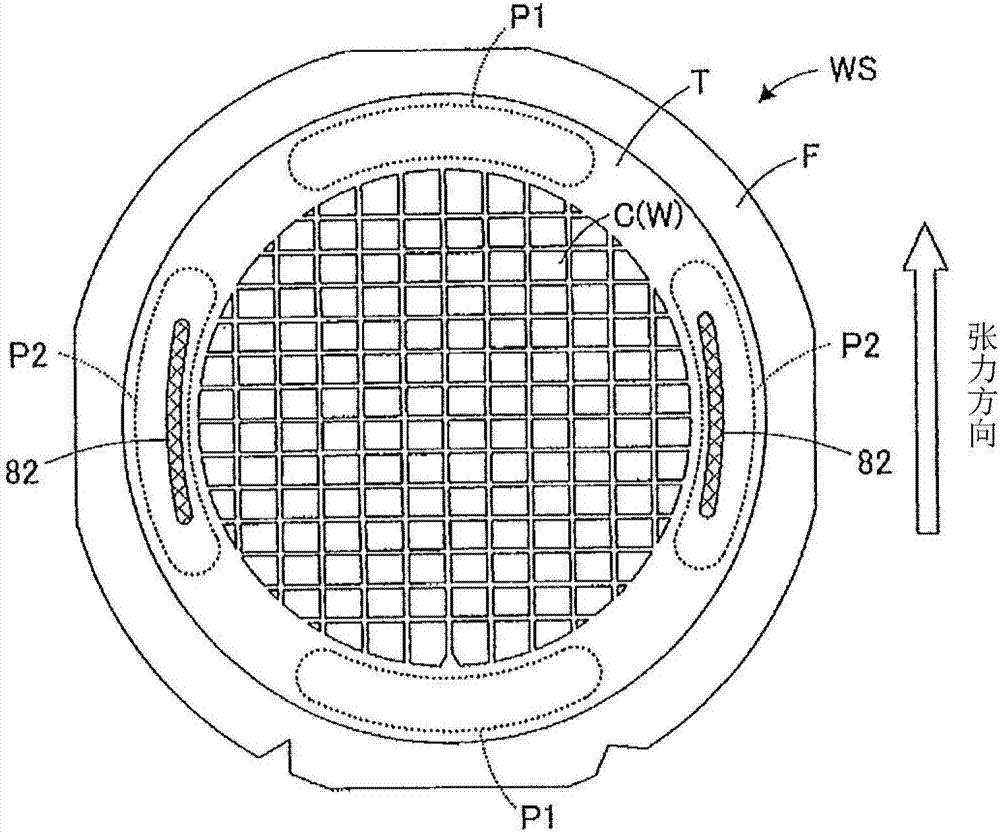

[0030] Such as figure 1As shown, the dividing apparatus 1 is configured to divide the wafer W supported by the ring frame F through the tape T into individual chips by expanding the tape T. In addition, the dividing apparatus 1 is configured to release the expansion of the tape T while maintaining the chip interval, and to remove the gap between the outer periphery of the wafer W and the ring frame by heat shrink when the expansion of the tape T is released. The folds between the inner circumference of F. In this way, only th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com