Electromagnetic compatibility shielding cavity of a KVM all-in-one machine

An electromagnetic compatibility and all-in-one technology, applied in the direction of magnetic/electric field shielding, screening casings, electrical components, etc., can solve the problems of shielding overall sexual harassment, failure to consider, system loss, etc., to achieve the effect of ensuring electromagnetic compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

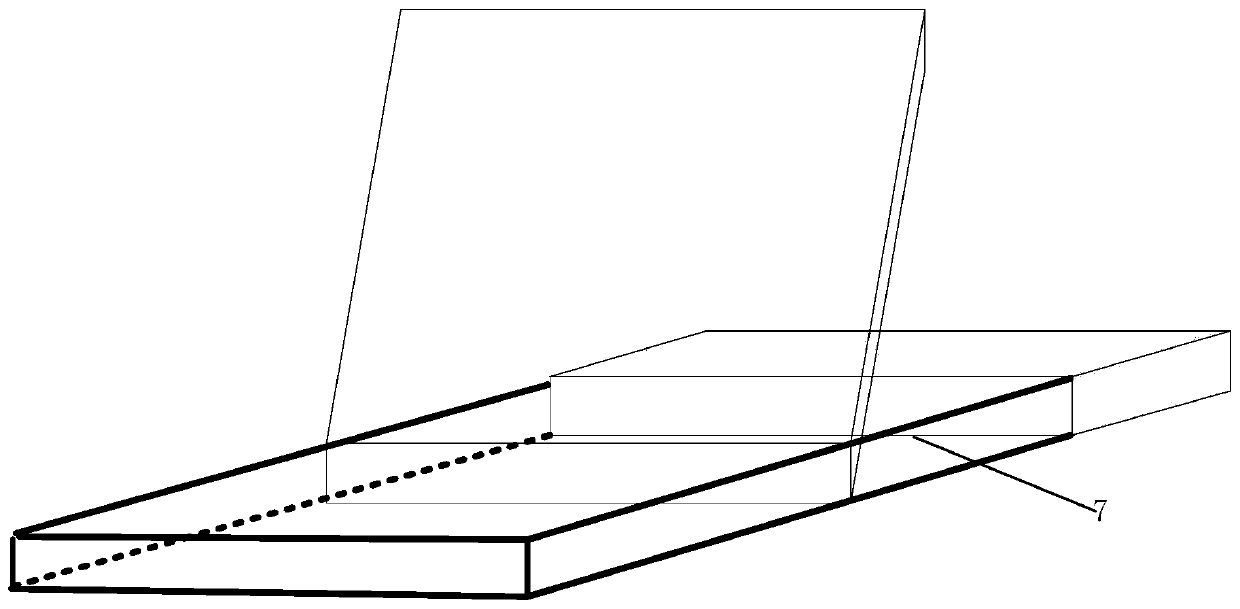

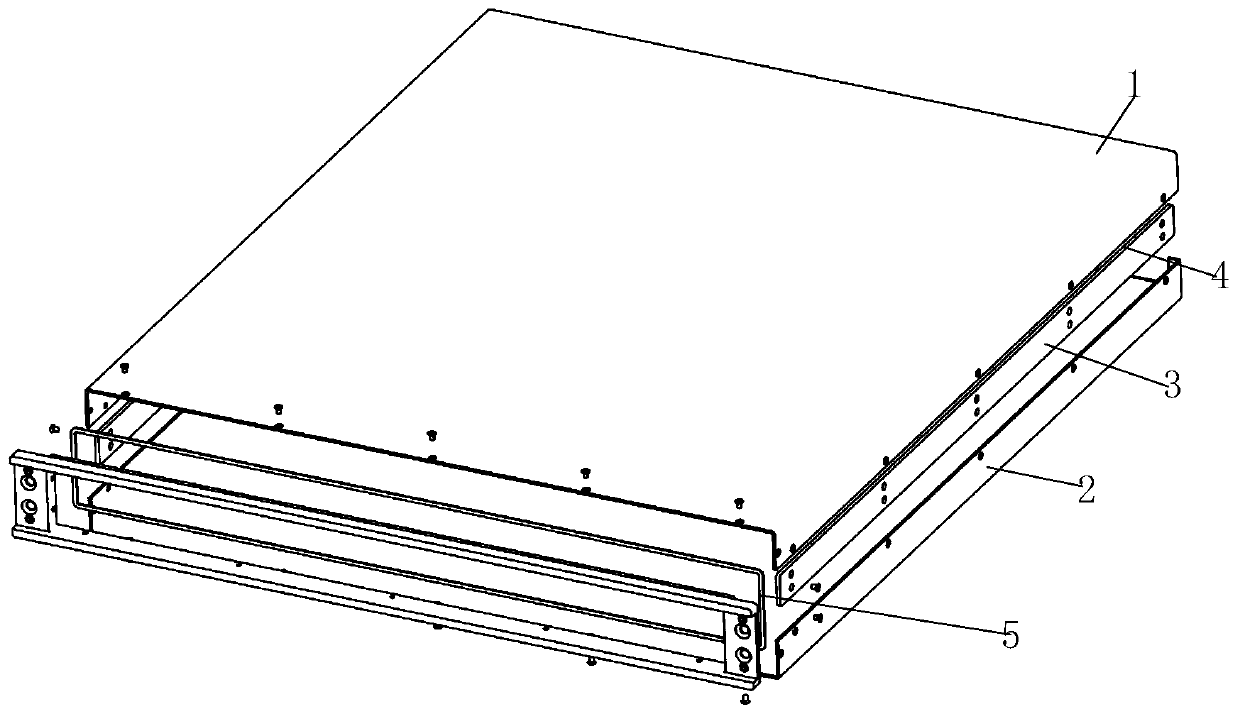

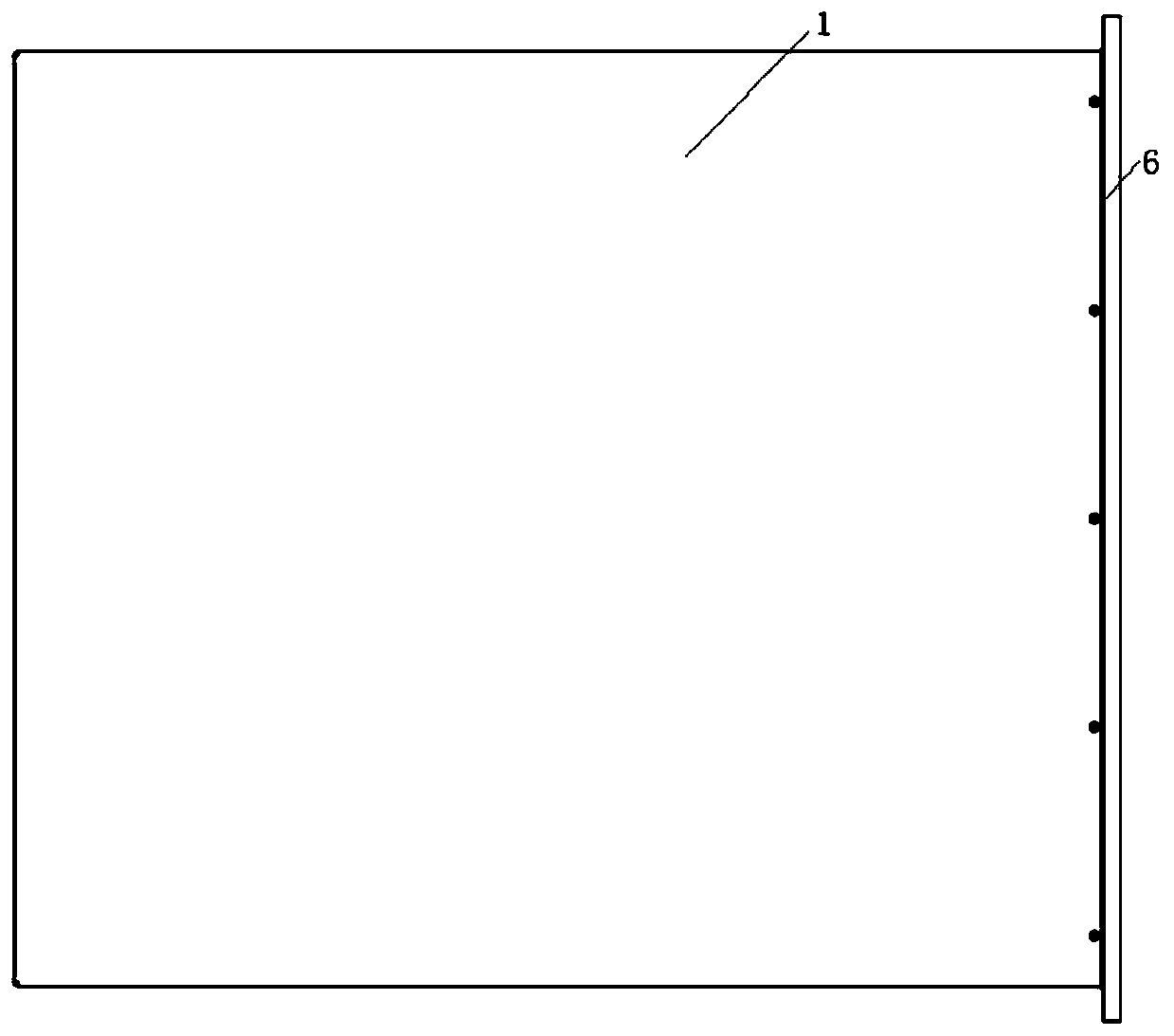

[0026] Such as Figure 1 to Figure 6 As shown, an electromagnetic compatibility shielding chamber of a KVM all-in-one machine includes a cavity surrounded by an upper cover 1 and a lower cover 2. The cavity is designed as a wrapping structure, so that there is no horizontal or vertical gap between the KVM all-in-one machine and the electromagnetic compatibility shielding cavity The structure of the vertical gap, the side walls of the upper cover 1 and the lower cover 2 are connected by the connecting strip 3, the upper cover 1, the lower cover 2 and the connecting strip 3 are all made of aluminum plates that have undergone conductive oxidation treatment, and the connecting strip 3 and the upper The outer surface of the connection between the cover 1 and the lower cover 2 is coated with copper foil 4, and the end of the cavity is provided with an inner buckle bending part 6, and the inner surface of the bending part 6 is coated with copper foil. A conductive cloth pad 5 is also...

Embodiment 2

[0032] Such as Figure 1 to Figure 6 As shown, an electromagnetic compatibility shielding chamber of a KVM all-in-one machine includes a cavity surrounded by an upper cover 1 and a lower cover 2. The cavity is designed as a wrapping structure, so that there is no horizontal or vertical gap between the KVM all-in-one machine and the electromagnetic compatibility shielding cavity The structure of the vertical gap, the side walls of the upper cover 1 and the lower cover 2 are connected by connecting bars, the upper cover 1, the lower cover 2 and the connecting bars 3 are all made of aluminum plates that have undergone conductive oxidation treatment, and the connecting bars 3 and the upper cover 1. The outer surface of the joint of the lower cover 2 is coated with copper foil 4, and the end of the cavity is provided with an inner buckle bending part 6, and the inner surface of the bending part 6 is coated with a conductive cloth gasket. The side wall of the head end is also pasted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com