Frying device for dried tofu production

A frying and dried tofu technology, which is applied in the direction of oil/fat roasting, etc., can solve the problem that there is no shovel plate and the dried tofu is easy to stick to the conveyor belt, so as to improve the utilization rate and prevent sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

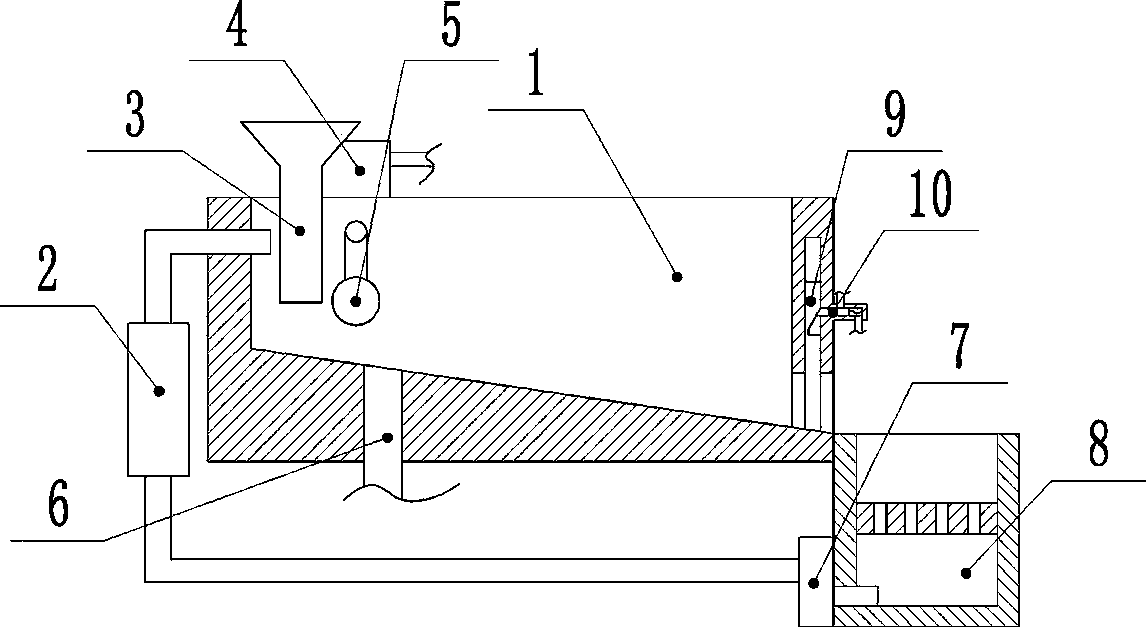

[0016] The reference signs in the accompanying drawings include: oil tank 1, electric heater 2, feed hopper 3, turbine 4, pendulum 5, intake pipe 6, oil pump 7, material receiving tank 8, sealing plate 9, wedge bar 10.

[0017] Example basic reference figure 1 Shown: a frying device for dried tofu production, including an oil tank 1 and an electric heater 2, the bottom of the oil tank 1 is inclined, the lower end of the bottom of the oil tank 1 has a discharge port, and a sealing plate 9 is slidingly connected in the discharge port, and the oil tank 1 There is a material receiving tank 8 at the outlet of the material receiving tank 8, a filter plate is arranged in the material receiving tank 8, an oil pump 7 is connected to the bottom of the material receiving tank 8, the oil pump 7 is connected to the top of the oil tank 1, and the pipeline between the oil pump 7 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com