Powder mixing device

A technology of mixing device and powder supply device, which is applied in the direction of mixer, mixing method, solid and solid mixing, etc., can solve the problems of insufficient powder mixing, inability to crush, uneven block powder, etc., and achieve simple equipment structure , fully mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

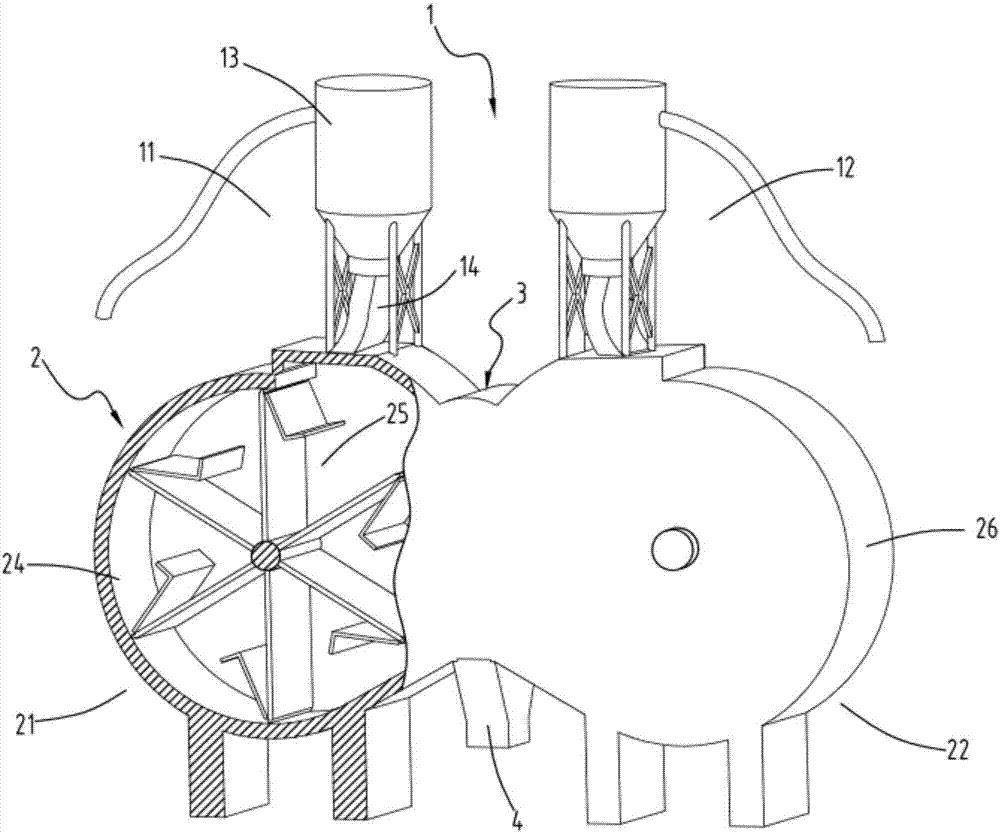

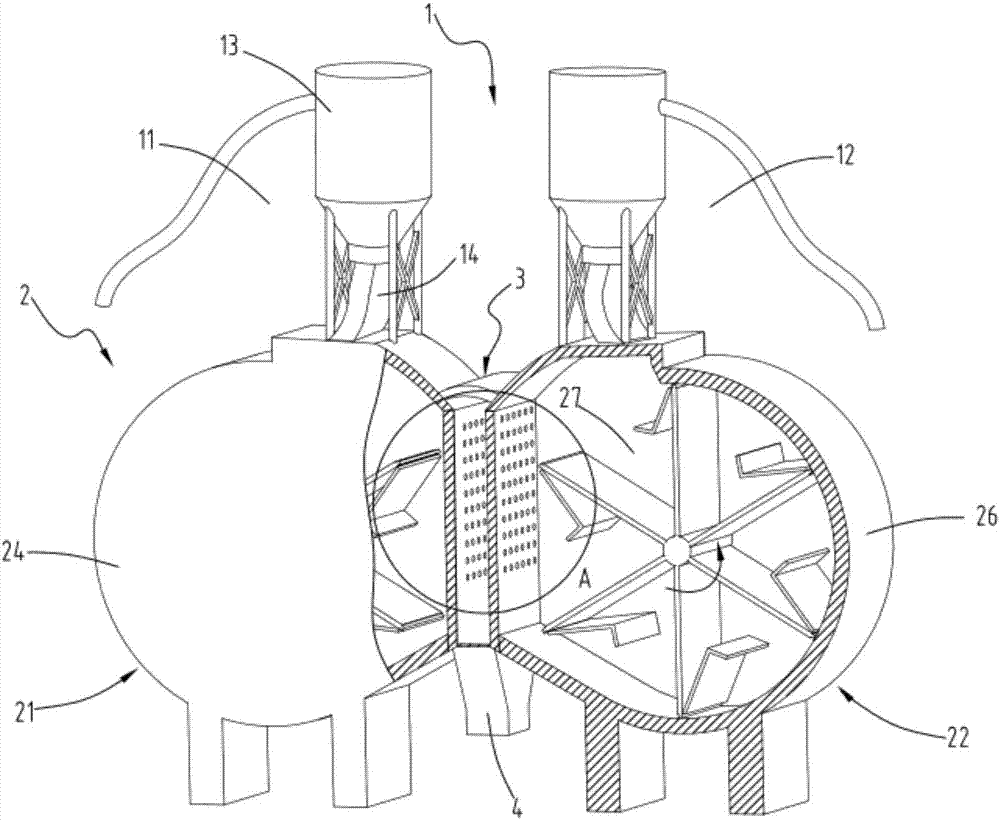

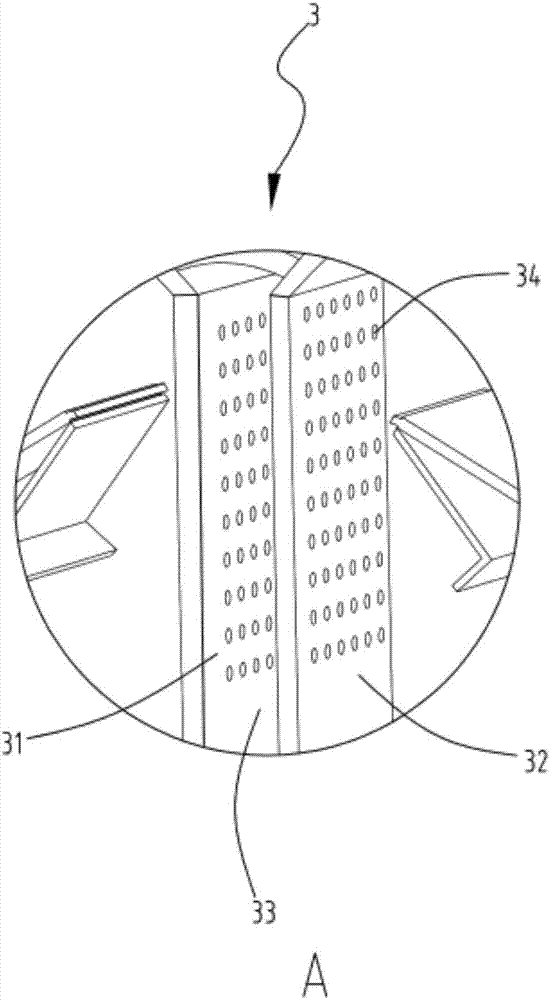

[0034] figure 1 It is a structural schematic diagram of a powder mixing device, figure 2 It is a schematic cross-sectional view of a powder mixing device, image 3 It is a schematic diagram of the enlarged structure of the powder mixing part, Figure 4 It is a schematic diagram of the structure of the powder throwing device, Figure 5 is the structural schematic diagram of the rotating part a, Figure 6 It is a schematic diagram of the enlarged structure of the pulverizing mechanism of the rotating part a, Figure 7 is the structural schematic diagram of the rotating part b, Figure 8 It is a schematic diagram of the structure of the powder support plate. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a powder mixing device includes a powder supply part 1, which includes a powder supply device a11 and a powder supply device b12; a powder rejection part 2, which includes a first powder rejection unit...

Embodiment 2

[0043] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the driving rods 401 and crushing rods 402 are arranged alternately along the width direction of the swinging plate 100, and the driving rods 401 and the driving rods 401 are not equidistantly arranged. The distance between the rod 401 and the driving rod 401 is 0.6cm-1.5cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com