Single plate rolling type lamination production equipment

A production equipment and rolling technology, which is applied in the field of veneer rolling lamination production equipment, can solve the problem of a large number of air bubbles in the film, and achieve the effect of firm adhesion, cost saving and consistent amplitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

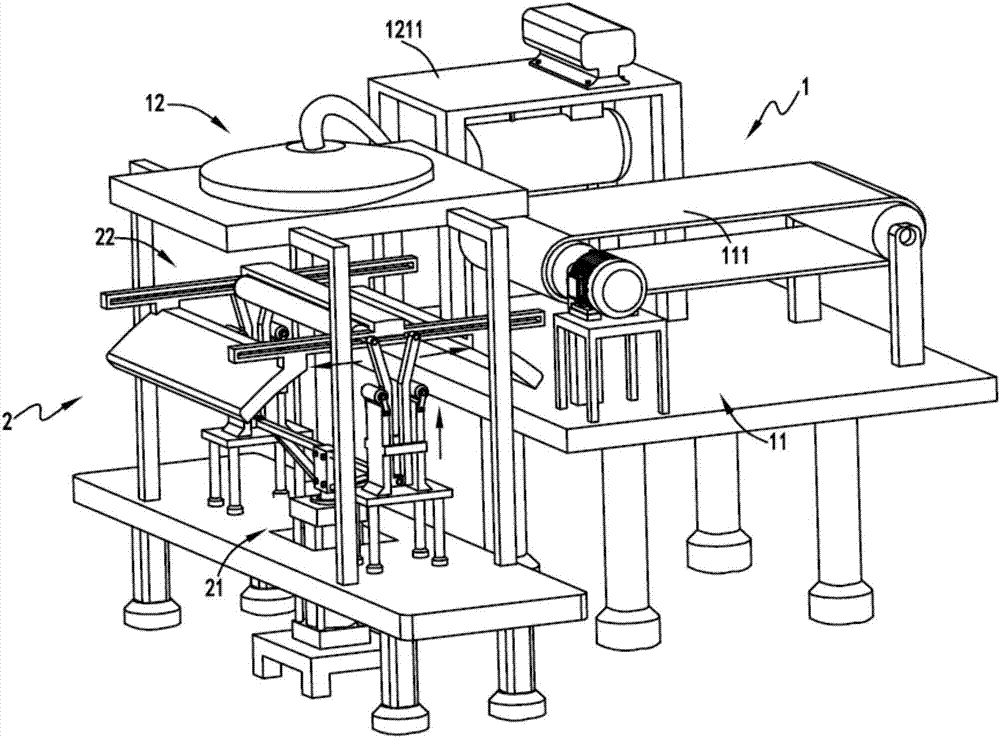

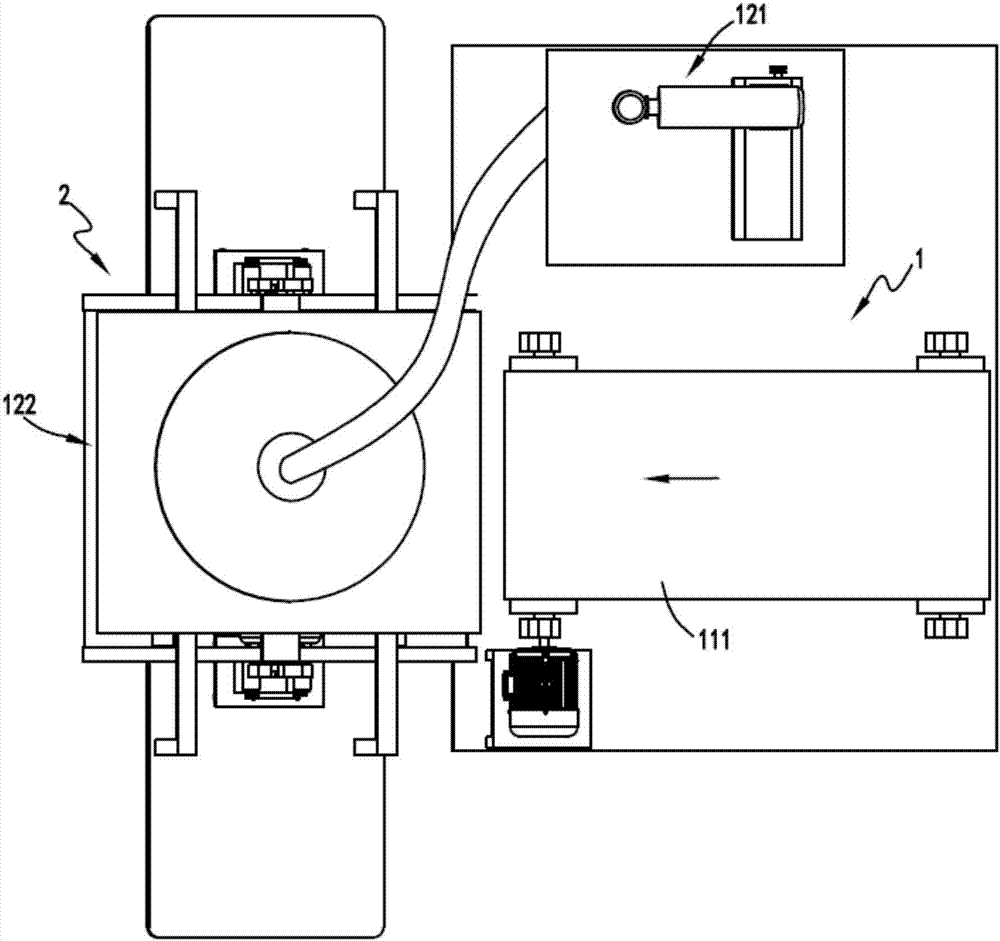

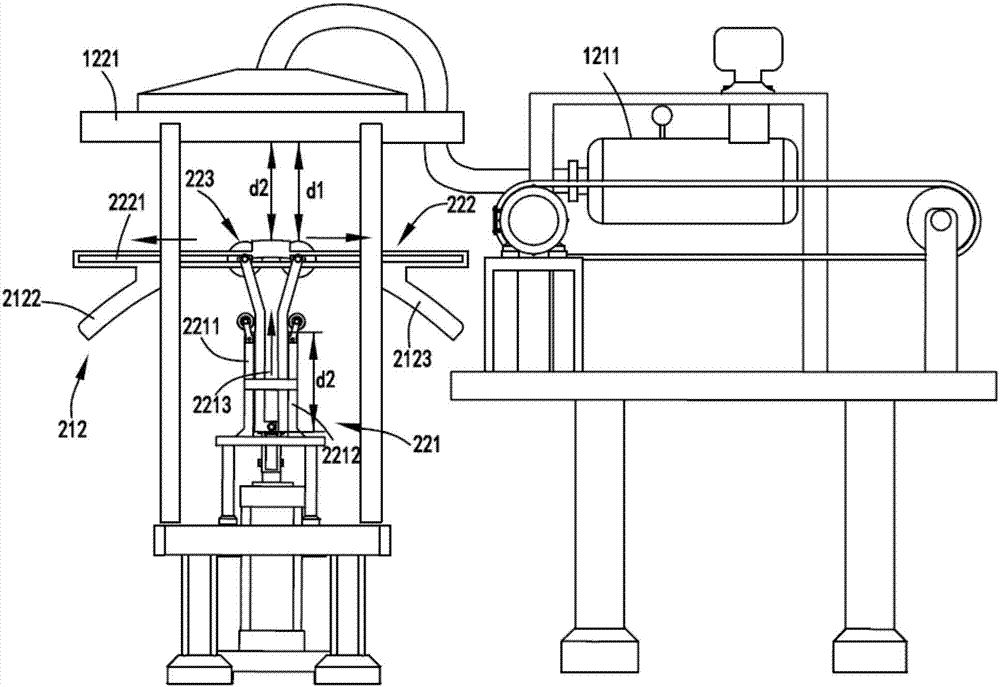

[0032] figure 1 It is a schematic diagram of the structure of the veneer rolling film production equipment, figure 2 It is a schematic top view of the veneer rolling film production equipment, image 3 It is a schematic diagram of the front view of the veneer rolling film production equipment, Figure 4 It is a schematic diagram of the structure of the film part, Figure 5 Schematic diagram of the structure when the smoothing mechanism completes the smoothing of the film, Image 6 It is a schematic diagram of the structure when the lifting mechanism drives the film to contact the sheet, Figure 7 It is a partially enlarged schematic diagram when the film first contacts the sheet, Figure 8 It is a structural schematic diagram of the lifting device and the smoothing device. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, a veneer rolling type film production equipment includes a sheet material conveyi...

Embodiment 2

[0044] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: the upper ends of the limiting plate a2211 and the limiting plate b2212 are provided with a sliding guide device 3, and the sliding guide device 3 includes a mounting frame 31 and a rotatable setting Guide pulley 32 on mounting frame 31.

[0045] The setting of the sliding guide device 3 can make the smoothing roller a2237 and the smoothing roller b2238 unfold to both sides or can be more smoothly recovered in the limiting channel 2213 on the one hand, and on the other hand, the smoothing roller a2237 and the smoothi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com