Intelligent coiling device for fine-needle-pitch circular knitting machine ultrathin fabric

A technology of coiling device and knitting machine, which is applied in thin material handling, strip winding, transportation and packaging, etc., can solve the problems of uneven tension, unstable rotation of the cloth rolling sprocket, and fabric pulling, etc., to improve the quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

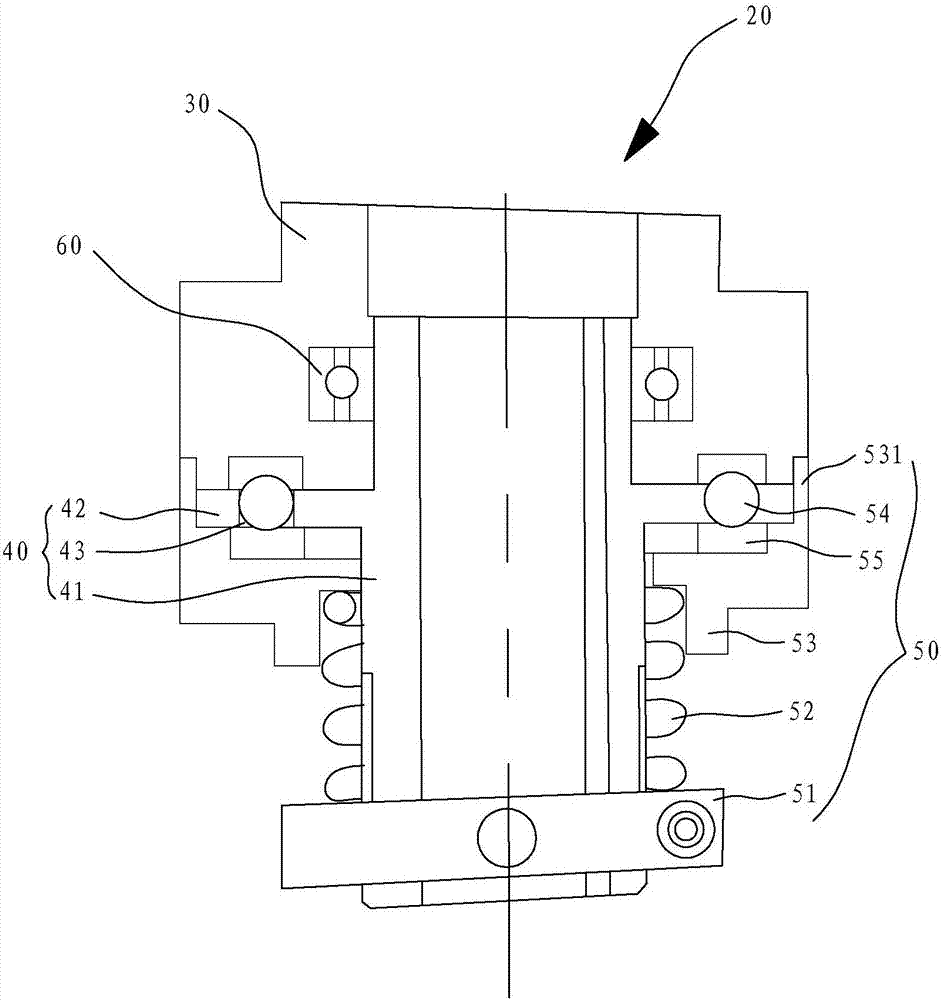

[0029] In order to further explain the technical solutions of the present invention, the present invention will be described in detail below through specific embodiments.

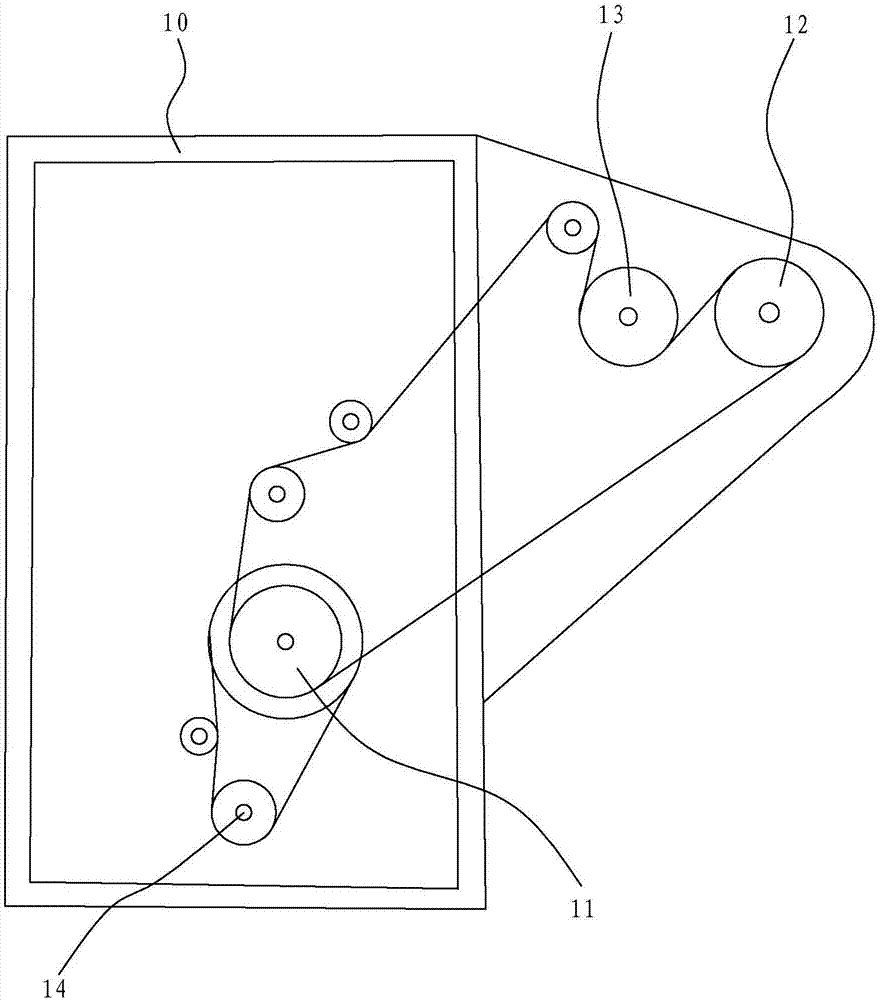

[0030] like figure 1 As shown, it is an intelligent winding device for ultra-thin fabrics of a fine-gauge disc knitting machine according to the present invention, comprising a servo motor, a main sprocket 11 , a first cloth clamping sprocket 12 and a second cloth clamping sprocket 13 , the cloth winding sprocket 14, the first cloth clamping rubber roller, the second cloth clamping rubber roller, the cloth winding rubber roller, the fabric size sensor and the controller, the controller can use a commonly used single chip computer or PLC.

[0031] The servo motor drives the main sprocket 11 to rotate, and the main sprocket 11 drives the first cloth clamping sprocket 12 and the second cloth clamping sprocket 13 to rotate through the first chain. The rubber rollers are fixedly connected, the second cloth clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com