Riser for heat insulation casting

A riser and thermal insulation material technology, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problems of time-consuming, high production cost, waste of wood, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

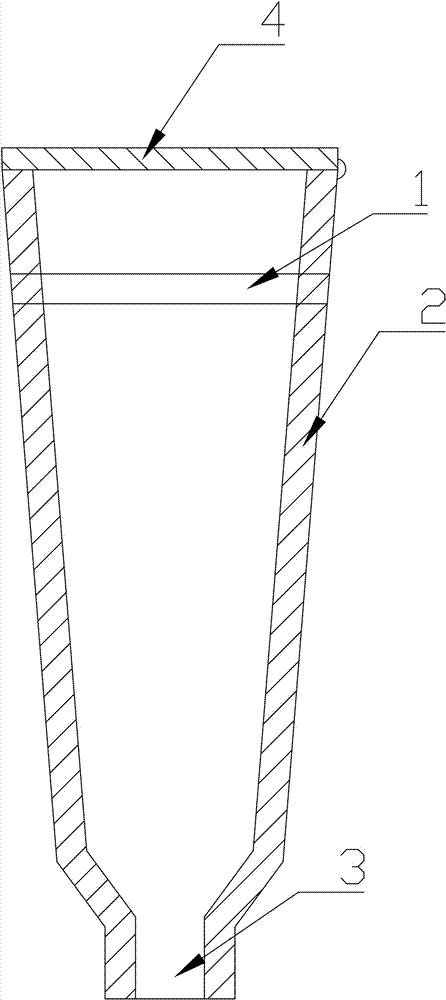

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. As shown in the figure, a hoisting steel bar 1 is added to the upper part of the cavity iron riser body 2, and a positioning hole 3 is left at the bottom of the riser body 2. The cavity structure can save material and reduce weight. The hoisting steel bar 1 on the upper part of the riser body 2 is convenient for hoisting and connection. The positioning hole 3 at the bottom of the riser body 2 can enhance the accuracy of installation. The top of the riser is equipped with a cover 4 , the cover 4 is made of thermal insulation material, which plays a thermal insulation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com