Rapidly mountable and dismountable four-pin conical die and operation method

A mold assembly and disassembly technology, applied to molds, manufacturing tools, ceramic molding machines, etc., can solve problems affecting the quality of tetrapod cone prefabrication, difficulty in pushing the upper formwork, and complicated disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

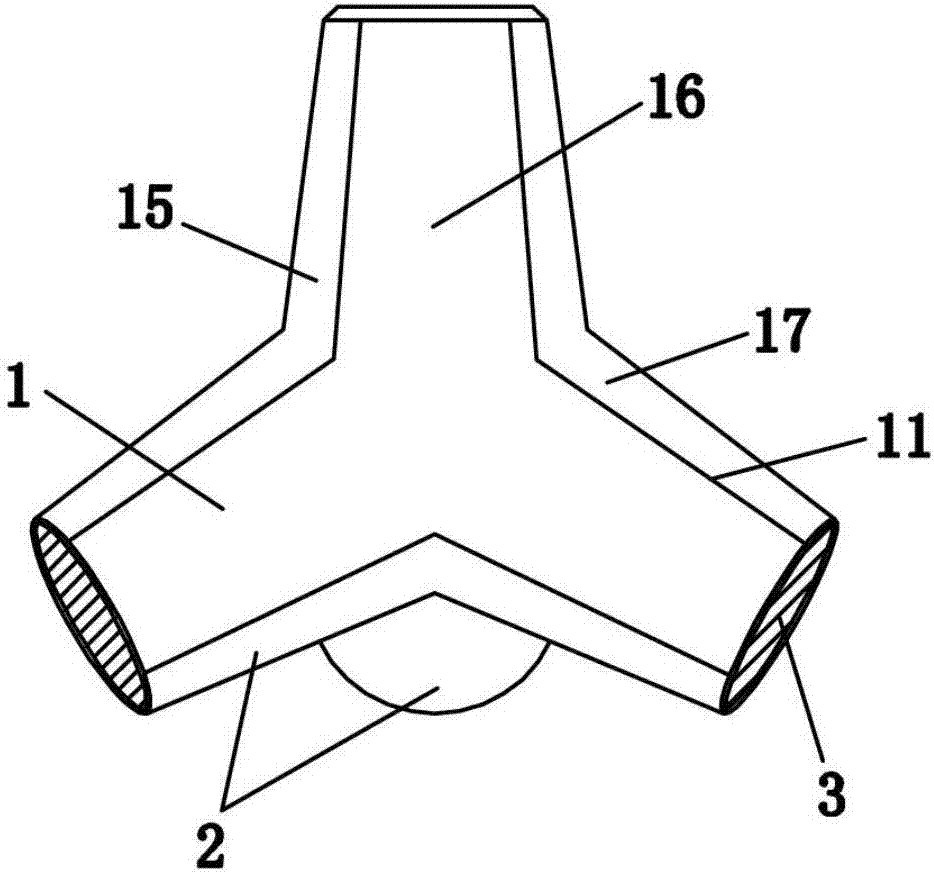

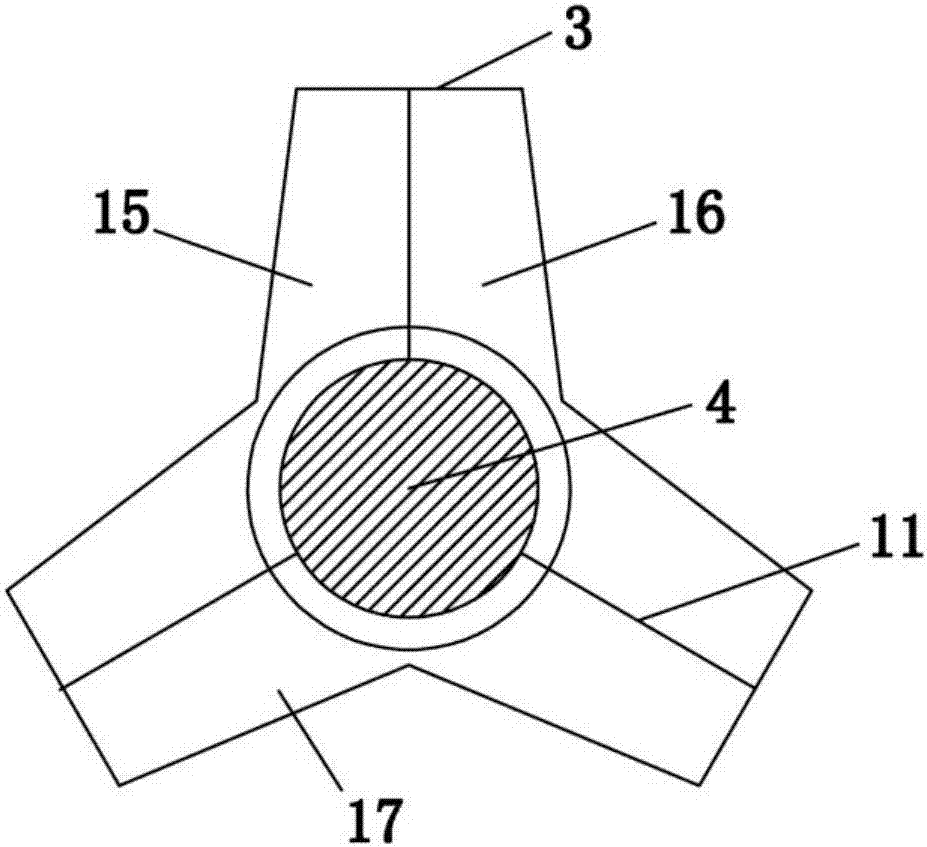

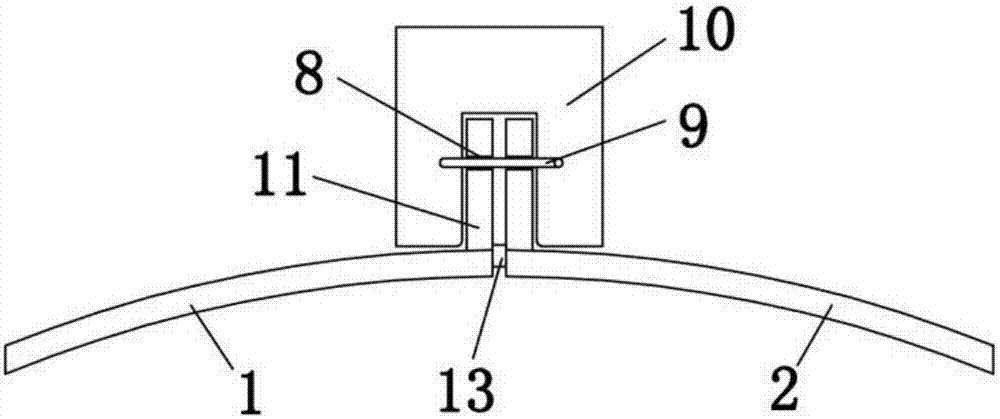

[0032] Such as figure 1 and figure 2 As shown, a four-legged cone mold that can be quickly assembled and disassembled according to the present invention includes an upper mold 1, a bottom mold 2 and a sealing plate 3, and the upper mold 1, the bottom mold 2 and the sealing plate 3 are correspondingly arranged to form a four-legged cone mold , upper mold 1 and bottom mold 2 are fixedly connected by a fixing mechanism, upper mold 1 includes side mold one 15, side mold two 16 and side mold three 17, side mold one 15, side mold two 16 and side mold three 17 respectively Fixedly connected by a fixing mechanism, the first side mold 15, the second side mold 16, the third side mold 17 have the same shape and structure as the bottom mold 2, and are all provided with three ends, and the cross sections of the ends are all fan-shaped structures...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com