A kind of decarboxylase and its application

A decarboxylase and carboxyl technology, applied in the field of decarboxylase, can solve problems such as inactivity, and achieve the effect of important industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

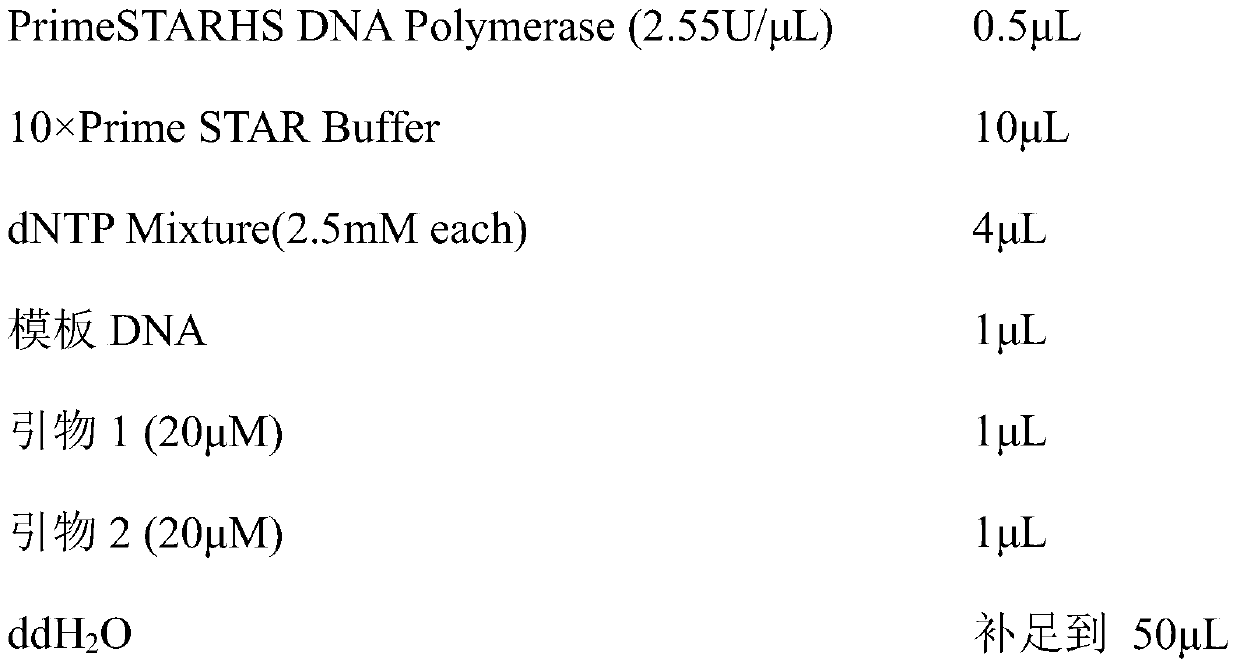

[0019] This example is the cloning of the decarboxylase gene described in the present invention and the construction of Escherichia coli engineering bacteria.

[0020] 1. Extraction of Proteus mirabilis ATCC 25933 DNA

[0021] The Proteus mirabilis ATCC 25933 strain was cultured in LB medium for 12 hours, centrifuged at 12,000rpm for 10 minutes to obtain the bacterial cells, and the bacterial genome DNA extraction kit (TaKaRa Company) was used to extract the total genomic DNA of the bacterial cells according to the operation, and stored in the refrigerator for later use.

[0022] 2. Competent preparation of Escherichia coli

[0023] (1) Inoculate E. coli DH5α and BL21(DE3) into 250 mL shake flasks containing 20 mL LB medium respectively, and culture overnight at 37° C. and 200 rpm.

[0024] (2) Inoculate in 50mL LB medium according to 1% inoculum amount, and cultivate to OD at 37°C 600 About 0.6 (about 2 ~ 3h).

[0025] (3) Transfer the bacterial solution to a 50 mL pre-coo...

Embodiment 2

[0053] This example is the induced expression and separation and purification of the decarboxylase described in the present invention.

[0054] 1. Add 500 μL of recombinant bacteria solution to 50 mL of LB culture solution. Cultivate at 37°C for 2.5h, and stand at 15°C for 0.5h. Then add 40 μL of 0.5M IPTG, and culture for 24 hours under cold induction at 15°C. Centrifuge the fermentation broth (8000rpm, 10min) to obtain the bacterial cells, redissolve the bacterial cells with disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution (20mmol / L, pH 7.4), crush them with an ultrasonic breaker, and collect them by centrifugation (8000rpm, 10min) The supernatant was used to obtain a crude enzyme solution.

[0055]2. Use the AKTA avant 150 protein purification system to purify the crude enzyme liquid obtained in step 1 with a nickel column. The elution method is: put the four pipelines A1, A2, B1, and B2 into water, and set the system flow to 20mL / min flow rate, e...

Embodiment 3

[0057] This example is the optimum temperature of the decarboxylase of the present invention. With 3,4-dihydroxyphenylpyruvate (10mM) as the substrate, the substrate and the phosphate buffer solution with pH 7.4 were bathed in water for 15min under different temperature conditions of 20-70°C to measure the activity of decarboxylase and determine the enzyme The optimum reaction temperature is 40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com