Extraction and purification method of capsular polysaccharide in 336-type staphylococcus aureus

A technology for capsular polysaccharide and staphylococcus, applied in the biological field, can solve problems such as unfavorable expansion of production by solid culture method, and achieve the effects of easy clinical production, simple method and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

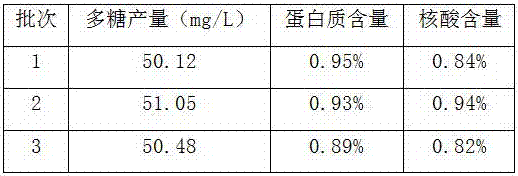

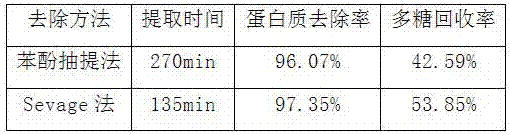

Embodiment 1

[0037] Extraction and purification of capsular polysaccharide of Staphylococcus aureus type 336:

[0038] 1. Fermentation and cultivation of Staphylococcus aureus type 336

[0039] 1. Culture medium configuration: Take 35g of Columbia medium according to the instructions, add appropriate amount of distilled water to dissolve, adjust the pH to 7.0 with 2M NaOH or 1M HCl hydrochloric acid, adjust the volume to 1L with distilled water, autoclave at 121°C for 15 minutes, and cool to room temperature Finally, add 2% volume ratio of sterile whey and put it in a 4°C refrigerator for later use.

[0040] 2. Cultivation of seed liquid: open the frozen strain J581, inoculate 2 mL of Columbia Broth (CB) with 1% inoculum, and culture at 37°C for 10 hours to obtain a first-class seed fermentation liquid; take 0.3 mL of first-class seeds The solution was inoculated into a 30mL Columbia broth conical flask, shaken and cultured on a shaking table (37°C, 200rpm / min) for 12h to obtain a working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com