Bladeless wind driven generator

A technology for wind turbines and generators, which is applied in the directions of wind turbines, wind turbine combinations, and wind power generation to achieve the effects of less vegetation damage and lower land occupation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

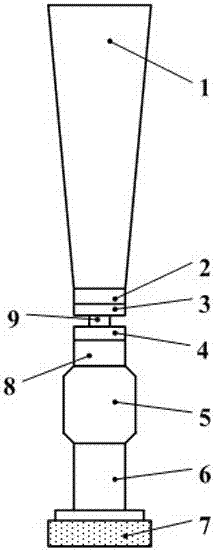

[0022] Embodiment 1, the present invention includes a conical wind tower 1, a connection plate 2, a permanent magnet upper plate 3, a permanent magnet plate 4, a connection support 9, an energy conversion device 8, a speed increaser 5, a generator 6 and a support 7; One end of the conical wind tower 1 is fixedly connected to the connection plate 2, and the connection plate 2 is connected to the permanent magnet upper plate 3 on the connection plate 2 to form a whole. The support 7 is provided with a generator 6, a speed increaser 5 One end is connected to the generator 6, and the other end is connected to the energy conversion device 8. The permanent magnet disk 4 is arranged on the energy conversion device 8. The permanent magnet upper disk 3 is connected with the permanent magnet disk 4 through a connection support 9, and the permanent magnet is connected to the permanent magnet disk 4. The magnetic poles on the opposite sides of the disk 3 and the permanent magnet disk 4 rep...

Embodiment 2

[0023] Embodiment 2, the conical wind tower 1 of the present invention, the connecting support 9 and the energy conversion device 8 are connected together to form a whole; when the wind acts on the conical wind tower 1, due to the Karman vortex street principle, the conical wind will The tower 1 generates a periodic alternating lateral force, which causes the conical wind tower 1 to generate periodic vibrations. The vibration frequency and amplitude obtained by the conical wind tower 1 are transmitted to the energy conversion device 8 through the connecting support 9, thereby realizing the conical wind tower 1. The transmission and transformation of the wind energy obtained by the wind tower 1. refer to figure 1 , all the other are with embodiment 1.

Embodiment 3

[0024] Embodiment 3, the permanent magnet upper disk 3 of the present invention is fixed on the connection disk 2, the permanent magnet disk 4 is fixed on the outer end of the energy conversion device 8, the relative planes of the permanent magnet upper disk 3 and the permanent magnet disk 4 are kept parallel, and The magnetic poles on the opposite planes of the permanent magnet upper disk 3 and the permanent magnet disk 4 repel each other; when the conical wind tower 1 deflects under the action of the wind, the permanent magnet upper disk 3 also deflects correspondingly, while the permanent magnet disk 4 remains unchanged. Therefore, the relative planes of the permanent magnet upper disk 3 and the permanent magnet disk 4 are no longer kept parallel, and the repulsive force generated by the short side will be greater than that of the long distance, forcing the permanent magnet upper disk 3 to return to the permanent magnet disk. 4, thereby driving the conical wind tower 1 to sw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com