Spiral compaction sealing type quick-opening device

A screw compression and sealing technology, applied in the direction of pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of difficult, inconvenient, and unfavorable operations, and achieve the effect of convenient operation, simple and reliable structure, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing:

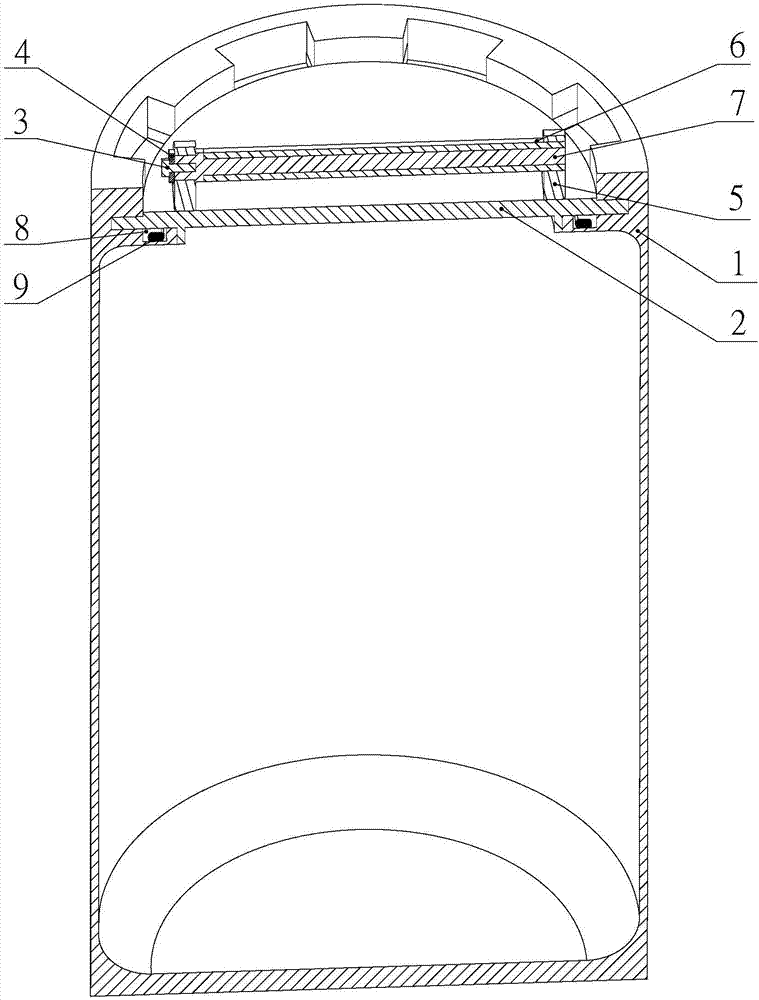

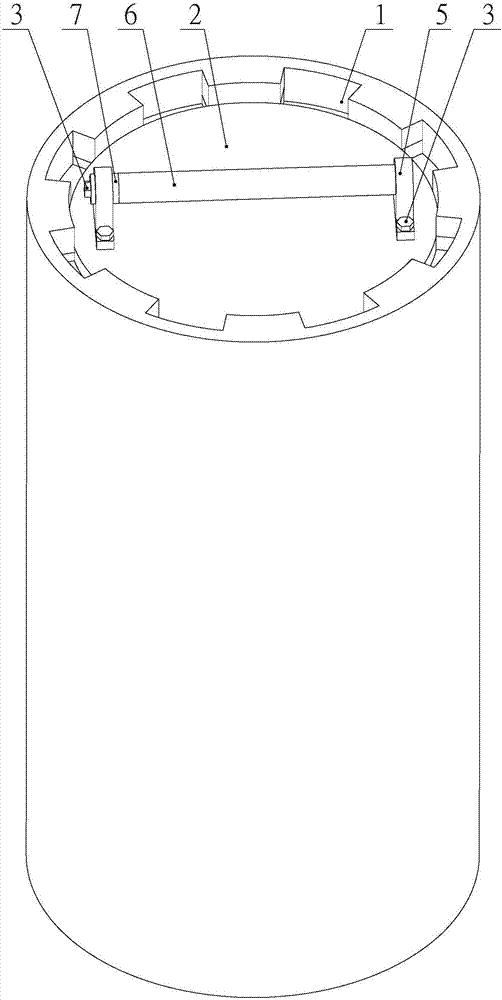

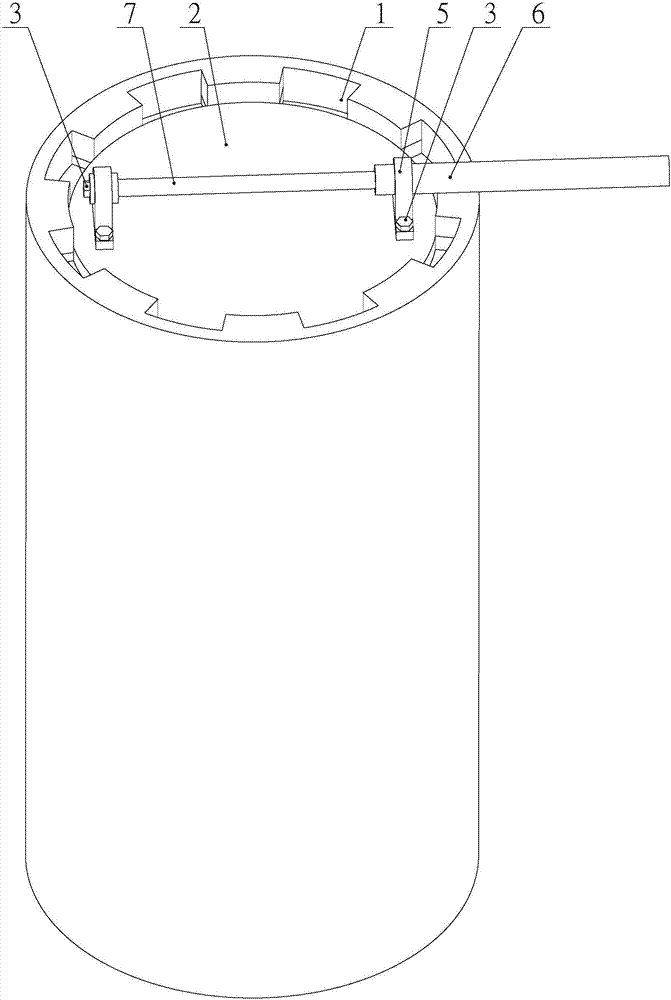

[0020] combine Figure 1~5 , the whole container includes the main body of the container, the quick-opening end cap and the sealing assembly. , O-ring 9.

[0021] The main body of the container 1 is spherical, and the end flange is processed with meshing teeth, grooves and bosses. The meshing surface of the meshing teeth is a helical surface with a certain thread lead angle. The thread lead angle should not be greater than the friction angle, which can realize automatic The lock has a groove processed on the boss, and the groove is used to place the seal. The sealing assembly includes a special sealing slip ring 8 and an O-ring 9. The special sealing slip ring 8 is placed on the O-ring 9, and its axial and radial directions have certain flexibility. Can guarantee a reliable seal.

[0022] The quick-opening end cap part mainly includes end cap 2, meshing teeth, support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com