Rapid repair method for damaged sealing surface of middle-high pressure steam system

A technology of a steam system and a repair method, which is applied to the sealing of engines, engine components, mechanical equipment, etc., can solve problems such as difficulty in repairing damaged sealing surfaces, leakage of steam pipes and equipment connection surfaces, etc., and saves equipment purchase and installation. Cost, shorten maintenance time, quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A rapid repair method for damaged sealing surface of a medium and high pressure steam system, the specific steps are:

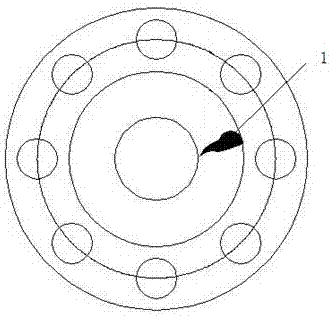

[0028] 1) Cleaning of damaged sealing surfaces

[0029] Clean the damaged sealing surface 1. According to the damage degree of the damaged sealing surface 1 and the precision of the equipment, use coarse sandpaper, fine sandpaper or plastic sandpaper to polish the damaged sealing surface 1. The grinding requirement is the damaged sealing surface 1. Metallic luster, then use a clean rag to clean the damaged sealing surface 1;

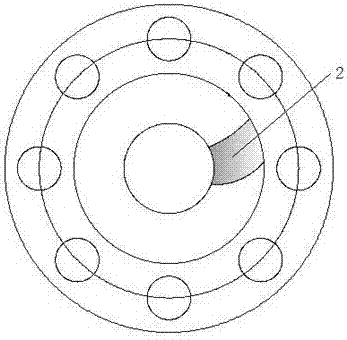

[0030] 2) Apply sealant to cover the damaged spots

[0031] Apply the sealant to the damaged part of the damaged sealing surface 1, or apply the entire sealing surface. The thickness of the sealant is required to be about 2mm higher than the sealing plane of the equipment;

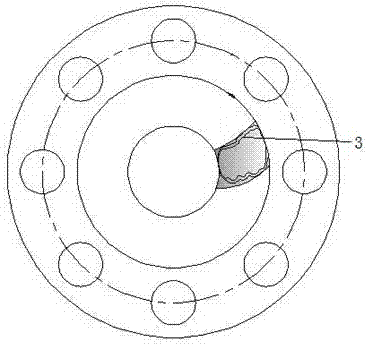

[0032] 3) Arrange the sealing rope

[0033] Arrange the sealing rope 3 along the damaged sealing surface 1 inside and outside each circle.

[0034] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com