LED array light source

A technology of LED array and LED substrate, applied in the field of LED array light source, can solve the problems of unfavorable light gathering, low light utilization rate, large light source area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

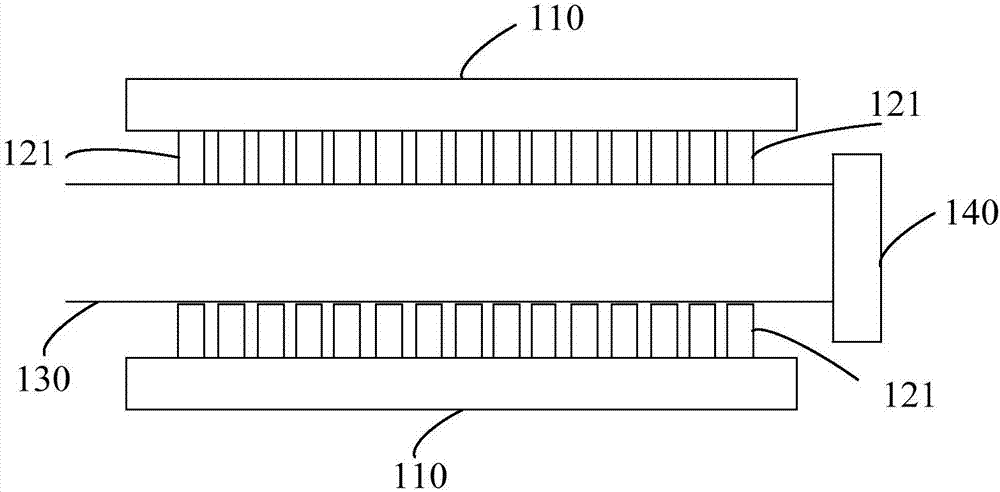

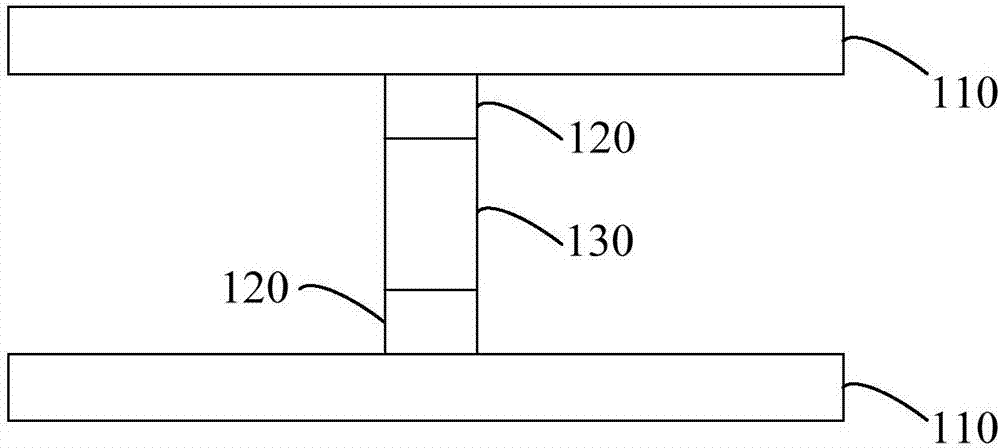

[0010] refer to figure 1 and figure 2 , the LED array light source in one embodiment includes an LED substrate 110 , an LED array 120 , a filter film (not shown in the figure) and a transparent rod 130 . The filter film is arranged on the outer wall of the transparent rod 130; the LED array 120 is fixed on the side of the LED substrate 110 close to the transparent rod 130, electrically connected to the LED substrate 110, and the LED array 120 is arranged on the side of the transparent rod 130 provided with the filter film .

[0011] The light emitted by the LED array 120 enters the transparent rod 130 through the filter film, and the light in the transparent rod 130 is emitted from one end of the transparent rod 130 after being reflected by the filter film.

[0012] The LED substrate 110 is used for the normal operation of the LED array 120 . As a luminous body, the LED array 120 is composed of multiple light-emitting devices, which can be in one row or in multiple rows an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com