Condenser and refrigeration system

A condenser and condensation chamber technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of single oil return outlet, affect heat exchange efficiency, unfavorable oil return, etc., and achieve the goal of improving oil separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

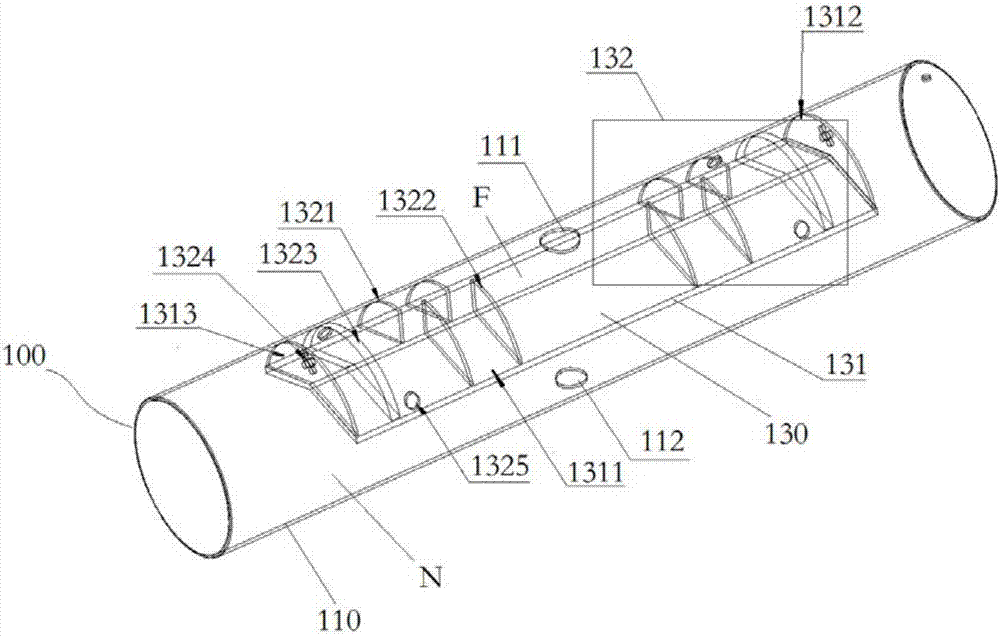

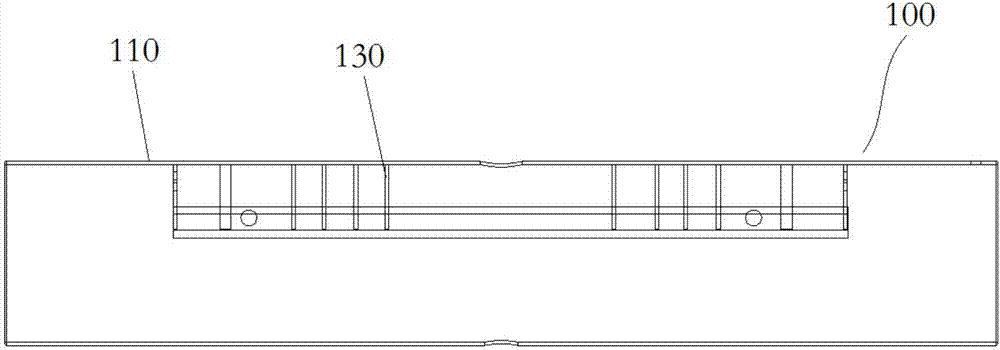

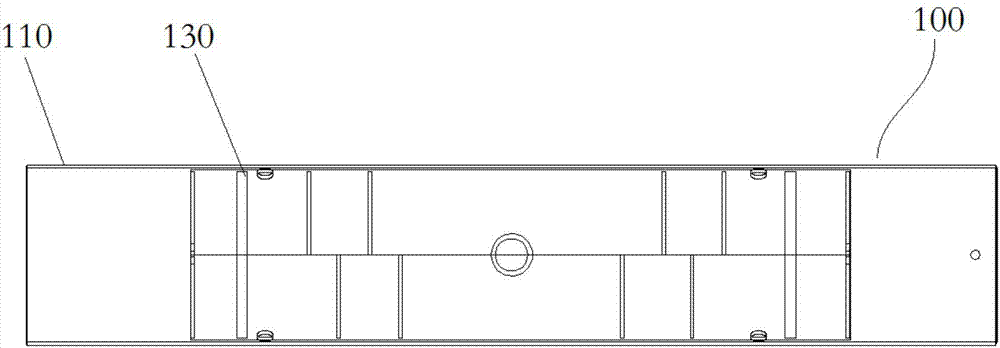

[0072] Figure 1 to Figure 5 A structural diagram of the condenser 100 according to the first embodiment of the present invention is shown.

[0073] like Figure 1 to Figure 5 As shown, the condenser 100 includes a housing 110 , a condenser tube bundle 120 and an oil separation device 130 . The condenser tube bundle 120 is disposed in the condenser chamber N along the front-rear direction. The casing 110 has a refrigerant inlet 111 that communicates with the oil separation chamber F and a refrigerant outlet 112 that communicates with the condensation chamber N.

[0074] The oil separation device 130 includes an inner partition 131 and an oil separation structure 132 . like Figure 1 to Figure 5 As shown, in the first embodiment, the refrigerant inlet 111 is located in the middle of the housing 110 in the front-rear direction, and the oil separation device 130 includes two oil separation structures 132 arranged on the front and rear sides of the refrigerant inlet 111 respec...

no. 2 example

[0090] Figure 6 to Figure 10 The structure of the condenser 200 of the second embodiment of the present invention is shown.

[0091] like Figure 6 to Figure 10 As shown, the difference between the second embodiment and the first embodiment is that, in the second embodiment, the four baffles include two upper baffles 2321 arranged on the upper side of the oil separation chamber F and two upper baffles 2321 arranged on the oil separation chamber F. The two lower baffles 2322 on the lower side of F, the upper baffles 2321 and the lower baffles 2322 are alternately arranged.

[0092] Suppose the cross-sectional area of the oil separation chamber F is S, the area of the upper baffle 2321 is S3, and the area of the lower baffle 2322 is S4, then preferably, 0.3S≤S3≤0.8S, 0.3S≤S4≤0.8 S. For example, both S3 and S4 may be 0.5S.

[0093] For the parts not described in the second embodiment, reference may be made to the related contents of the other embodiments.

no. 3 example

[0095] Figure 11 The structure of the oil separation device 330 of the condenser according to the third embodiment of the present invention is shown.

[0096] like Figure 11 As shown, the difference between this embodiment and the first embodiment is that, in this embodiment, the oil separation device 330 only includes an oil separation structure 332 located at the front side of the refrigerant inlet. In this embodiment, the rear sealing plate 3312 is completely enclosed to prevent the refrigerant from entering the condensation chamber without oil separation.

[0097] For the parts not described in the third embodiment, reference may be made to the related contents of the other embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com