Exhaust pipe structure and compressor

A technology for exhaust pipes and compressors, applied in the field of compressors, which can solve the problems of reduced compressor performance, low oil separation efficiency, and short flow channels, etc., to achieve the effects of extending flow channels, improving oil separation efficiency, and increasing the collision separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

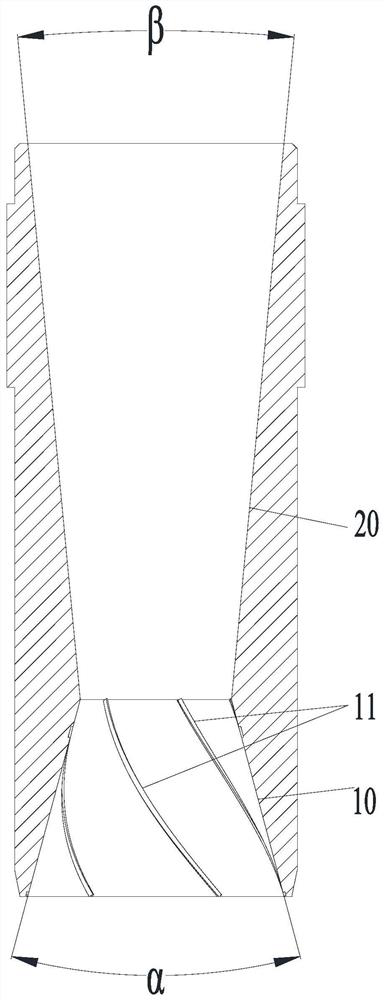

[0021] like figure 1 As shown, according to the structure of the exhaust pipe of the present invention, along the direction of airflow, there is a converging section 10 and a diverging section 20 inside the exhaust pipe. In the present invention, by setting the tapering section 10 and the diverging section 20, the oil-gas mixture will collide with the inner wall surface of the exhaust pipe tapering section 10 during the exhaust process, so that the oil and gas are separated. Then through the gradual expansion section 20, the airflow expands gradually, and finally discharges out the exhaust pipe relatively uniformly. Compared with the existing exhaust process, the entire process has a significantly longer flow path, and increases the collision separation process, effectively improving the oil separation efficiency.

[0022] Specifically, the end of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com