Oil-water mixture oil separation tank and oil separation system for swill separation

An oil-water mixture and oil tank technology, which is applied in separation methods, liquid separation, auxiliary equipment for liquid separation, etc., can solve the problems of insufficient purity and high water content in oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

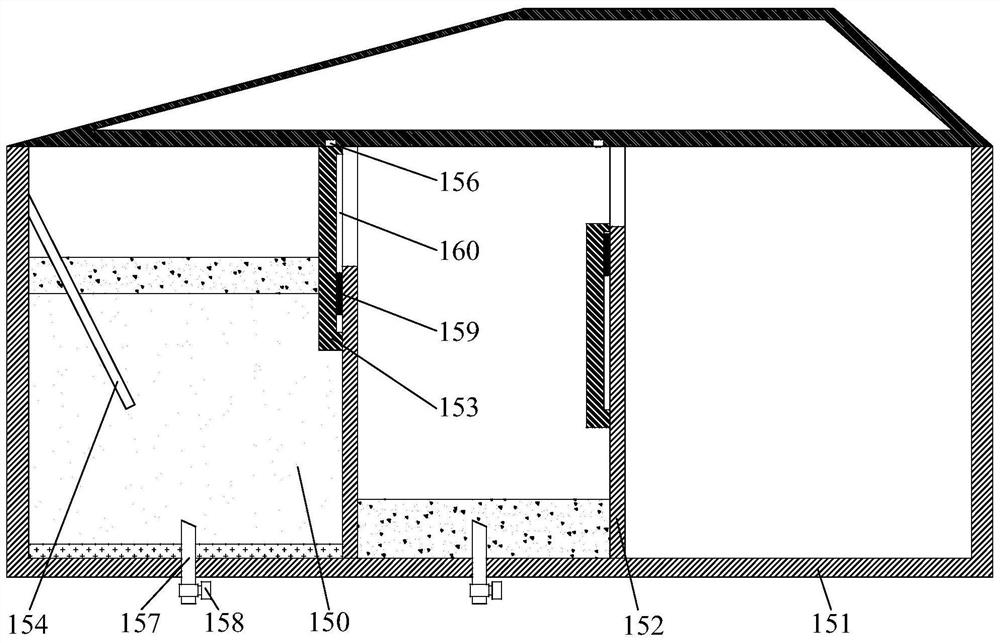

[0064] see figure 1 ,本实施例提供了一种泔水分离用的油水混合物隔油箱,其用于对油水混合液进行隔油分离,使液体按照密度分离成油层和水层。其中,该油水混合物隔油箱包括箱体151、隔板152、悬浮板153、缓冲板154、排水管157、水阀158以及进出料控制器,还可以包括进料管以及进料阀。

[0065] 箱体151可以由多块组装板组成,也可以采用一体成型结构进行使用。 箱体151的内外表面可以涂覆耐油涂料,可以保证油污不会腐蚀或堆积在箱体151的内壁或者外壁上。 箱体151上可以开设进料口,外部输入的油水混合物 / 液从进料口进入到箱体151内并在重力的作用下分层,上层为油层,而下层为水层,最下层为沉淀 Floor.

[0066] 隔板152的数量为多块,并且多块隔板152设置在箱体151中,而且平行设置,以将箱体151的内腔从其一侧至其另一侧分隔成相互连通的多个隔油空间163。其中,相邻的两个隔油空间163通过一块隔板152的上部空间连通。从箱体151的内腔的一侧至其另一侧,隔板152的高度依次增加,这样位于上层的油层会逐步转移至后一个隔油空间163,这样位于箱体151的内腔的另一侧的隔油空间163中的油层的厚度会非常大,从而收集到更多的油脂。这样,在油水混合物进入到前端的隔油空间163后,位于上层的油层会从该上部空间流入到另一个隔油空间163,如此往复,实现对油水混合物中油层和水层的多次分隔,使得最终分离出的油液中的含水率大大降低。隔板152靠近对应的悬浮板153的一侧具有凸条159,凸条159的数量至少为一根,并且凸条159的表面光滑。

[0067] 悬浮板153的数量为多块,而且每块悬浮板153与一块隔板152对应。每块悬浮板153活动安装在对应的隔板152上,并能够通过移动而盖住对应的隔板152的上部空间,以使位于对应的隔板152两侧的两个隔油空间163隔绝。其中,悬浮板153的密度位于油水混合物的油密度和水密度之间。在本实施例中,悬浮板153靠近对应的隔板152的一侧开设凹槽160,凹槽160的数量至少为一个,而且每个凹槽160与一根凸条159对应,并且每根凸条159限位在对应的凹槽160中。定义每块悬浮板153在纯净水中的浮力为F 1 ,每块悬浮板153在对应的隔板152上受到的摩擦力为F 2 ,每块悬浮板1...

Embodiment 2

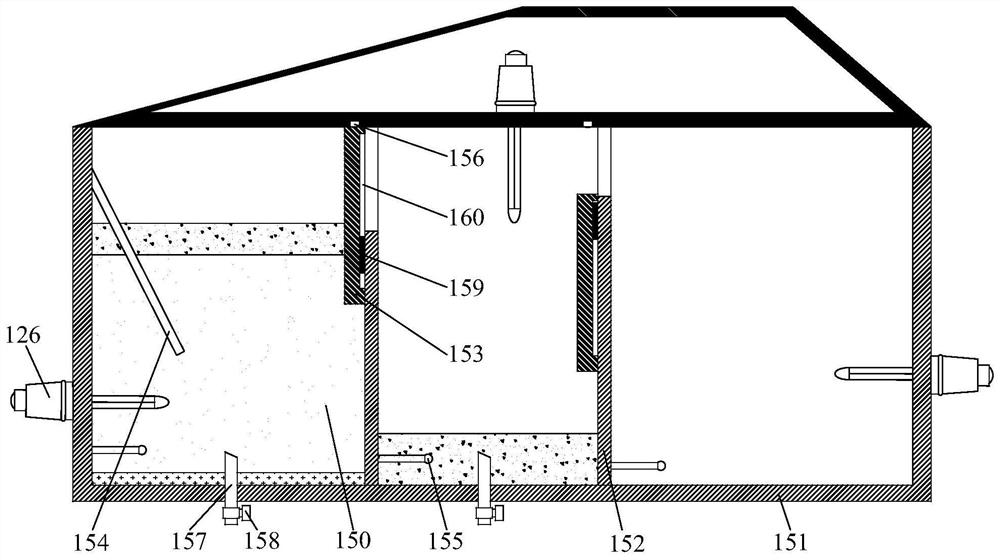

[0078] see figure 2 , the present embodiment provides an oil-water mixture oil separation tank for swill separation, and the oil separation tank adds a heating pipe 126, a temperature sensor 155 and a temperature controller on the basis of Embodiment 1.

[0079] There are multiple heating pipes 126 , and the multiple heating pipes 126 correspond to the multiple oil separation spaces 163 respectively. The heating pipe 126 is installed on the box body 151 and protrudes into the corresponding oil-separating space 163 for heating the oil-water mixture in the corresponding oil-separating space 163 . The heating tube 126 can be an existing heating tube, such as a U-shaped heating tube, which can keep the oil-water mixture in a liquid state all the time, so that the oil-water can be stratified without condensation.

[0080] There are multiple temperature sensors 155 , and each temperature sensor 155 corresponds to one heating pipe 126 . The temperature sensor 155 is installed on t...

Embodiment 3

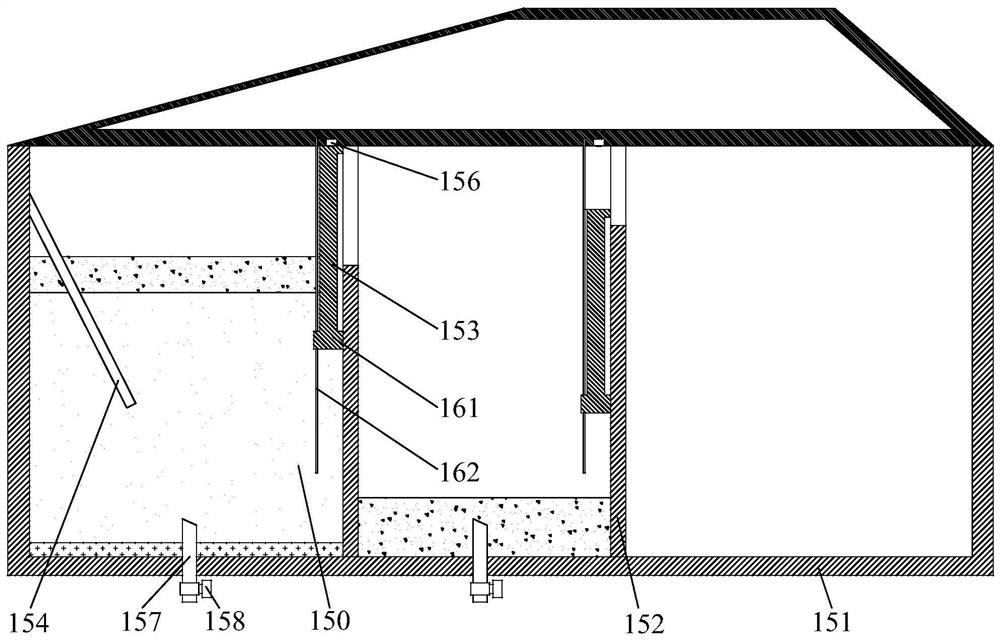

[0084] see image 3 , this embodiment provides an oil-water mixture oil-separation tank for swill separation, which is similar to that of Embodiment 1, except that the structure of the suspension plate 153 and the separator 152 is different. The bottom end of the suspension board 153 has steps 161, and the number of steps 161 is at least one layer. A sliding rod 162 is provided on a side of the partition 152 close to the corresponding suspension plate 153 , the number of the sliding rod 162 is at least one, and each sliding rod 162 corresponds to a step 161 . Each sliding rod 162 passes through the corresponding step 161 and is fixed on the top wall of the box body 151 . Moreover, lubricating oil can be provided at the connecting part of the sliding rod 162 and the sliding rod 162, and a smooth structure can also be used to reduce the friction between the sliding rod 162 and the step 161 and reduce the resistance of the suspension board 153, so that the suspension board 153 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com