Automatic sand and slag separation system for sand mold casting and slag and sand separation method

An automatic separation and sand casting technology, which is applied in the direction of casting molding equipment, manufacturing tools, cleaning/processing machinery of casting materials, etc., can solve the problems affecting sand casting, the cleanliness cannot meet the recycling requirements, and the waste cannot be recycled directly Reuse and other issues to achieve the effect of reducing process steps and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

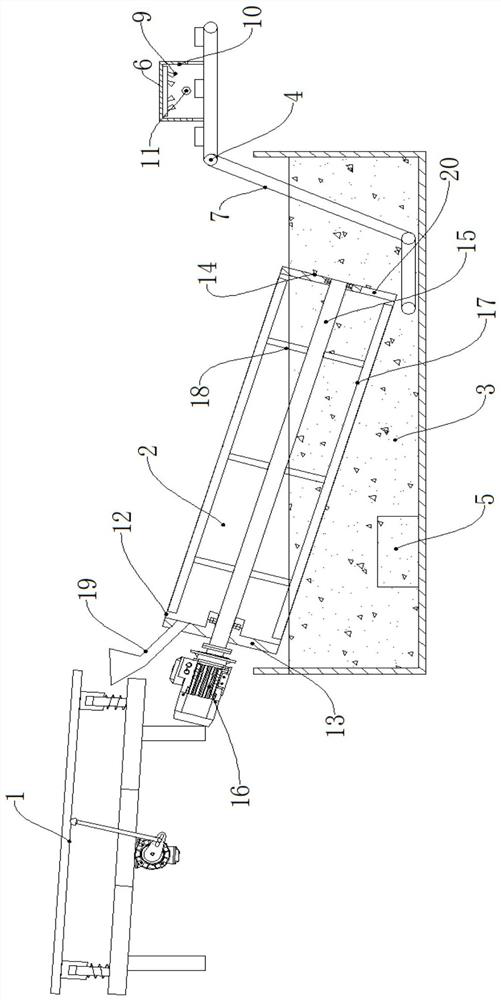

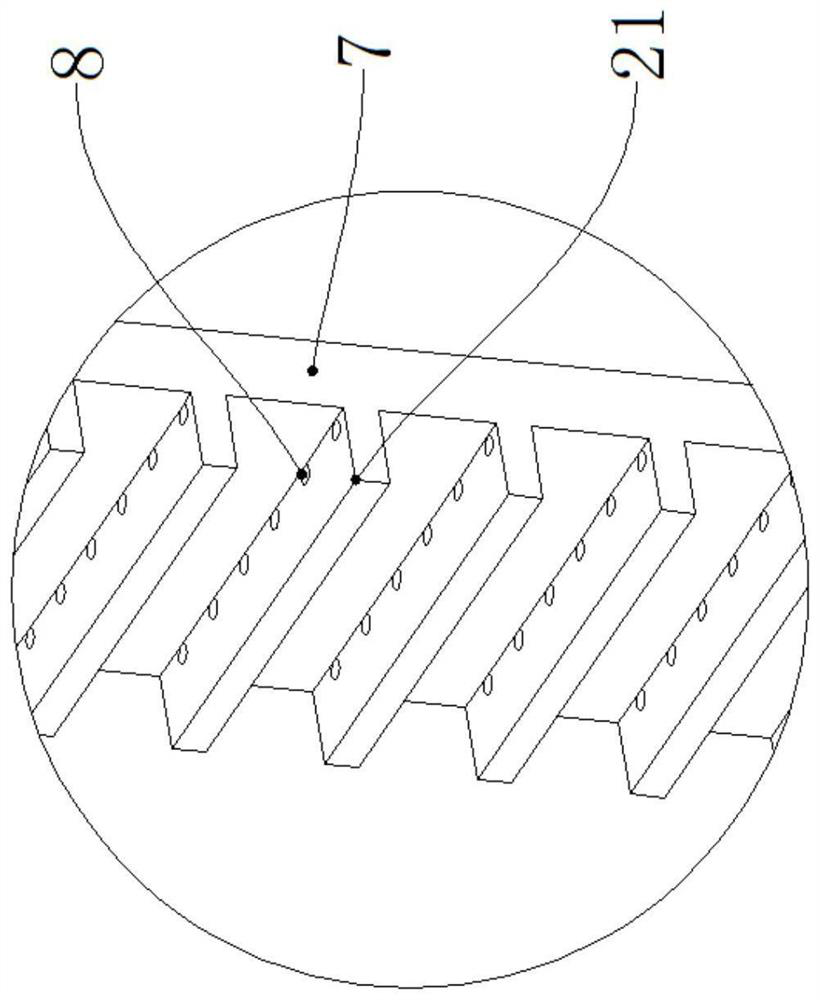

[0029] This embodiment discloses an automatic sand and slag separation system for sand casting, including a slag and sand primary separation component 1, a slag and sand secondary separation component 2 arranged at the discharge end of the slag and sand primary separation component 1, and a slag and sand secondary separation component 2 for A water bath heating assembly 3 for heating the slag in the slag sand secondary separation assembly 2 in a water bath, a transport assembly 4 arranged at the discharge end of the slag sand secondary separation assembly 2 and an ultrasonic generator set in the water bath heating assembly 3 device 5; the primary separation component 1 is used to vibrate the slag to realize the primary separation of the slag; the secondary separation component 2 is used to realize the secondary separation of the slag; the ultrasonic generator 5 is used to separate the slag Realize three separations; the transportation component 4 is used to transport the slag s...

Embodiment 2

[0040] This embodiment is further optimized on the basis of Embodiment 1. In this embodiment, the side of the cover 10 is provided with a return air port 11, and the return air port 11 is connected to the air inlet of the air heater; thus, in actual use, The hot air can be reused and the waste of resources can be avoided.

Embodiment 3

[0042] This embodiment discloses a method for separating sand and slag, including using an automatic sand and slag separation system for sand casting in Embodiment 1 or Embodiment 2; the specific sand and slag separation process is as follows:

[0043] S1: The slag sand is initially separated on the slag sand primary separation component 1, and the waste material and the molding sand are initially separated by vibration;

[0044] S2: The slag sand after preliminary separation enters the slag sand secondary separation component 2 for secondary separation, and at the same time achieves three separations under the action of the water bath heating component 3 component and the ultrasonic generator 5;

[0045]S3: The transportation component transports the slag and sand that has undergone secondary separation and tertiary separation through the slag-sand secondary separation component 2 and the ultrasonic generator 5 to the hot high-pressure air drying component 6 for drying and dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com