A graded spirulina desilting device

A spirulina and graded technology, applied in the field of graded spirulina desilting devices, can solve the problems of low efficiency, large amount of desilting work, a lot of manpower, etc., and achieve the effect of high efficiency and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

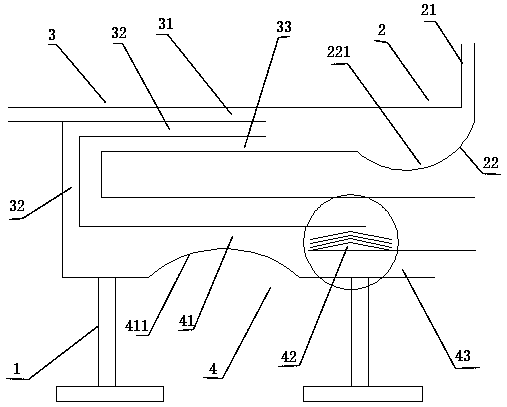

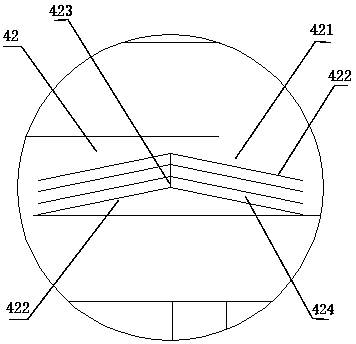

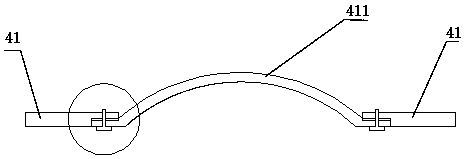

[0021] Such as figure 1 As shown, a graded spirulina desilting device includes a base 1 , a feeding mechanism 2 , a primary separation mechanism 3 , and a secondary separation mechanism 4 . The feeding mechanism 2 , the primary separation mechanism 3 and the secondary separation mechanism 4 are all installed on the base 1 . The feeding mechanism 2 includes a feeding pipeline 21 and a feeding pipeline 22 . The feeding pipeline 21 is located on the upper end side of the feeding pipeline 22 and communicates with each other. The feeding pipe 22 is provided with an arc-shaped feeding cavity 221 sunken to the bottom. The primary separation mechanism 3 includes a primary sediment discharge pipeline 31 , a mixture conveying pipeline 32 , and a primary spirulina discharge pipeline 33 . The first-stage sediment discharge pipeline 31 , the mixed mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com