Thin film transistor array substrate and liquid crystal display device

A thin-film transistor and array substrate technology, which is applied in the field of thin-film transistor array substrates and liquid crystal display devices, can solve problems such as high cost, high power consumption, and difficult implementation, so as to reduce standing angle, save power consumption, and improve light transmission rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

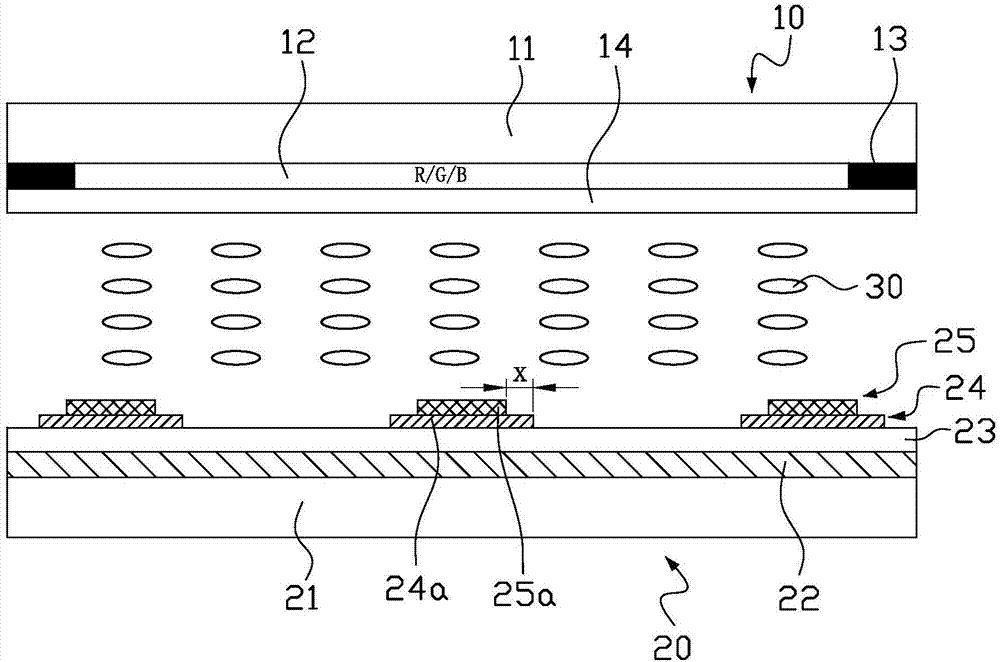

[0027] figure 1 It is a schematic cross-sectional structure diagram of a liquid crystal display device in the first embodiment of the present invention. The liquid crystal display device includes a color filter substrate 10 and a thin film transistor array substrate 20 disposed opposite to each other and a liquid crystal layer 30 sandwiched between them. For clarity, figure 1 2 only shows a schematic diagram of the cross-sectional structure of the liquid crystal display device corresponding to one of the sub-pixels (the R sub-pixel is taken as an example in the figure).

[0028] The structure of the color filter substrate 10 may not be limited. In this embodiment, the color filter substrate 10 includes a first substrate 11, and the first substrate 11 is provided with R, G, B three-color filter film 12 and light-shielding layer (BM) 13, light-shielding layer 13 is arranged between the light-shielding film 12 of different colors, is provided with flat layer (OC) 14 on the light...

no. 2 example

[0046] Figure 5 It is a schematic cross-sectional structure diagram of a liquid crystal display device in the second embodiment of the present invention, Figure 6 for Figure 5 For the schematic diagram of the circuit of the liquid crystal display device, please refer to Figure 5 and Figure 6 The main difference between this embodiment and the above-mentioned first embodiment is that the first electrode 22 in this embodiment is a pixel electrode, and the second electrode 24 is a common electrode, that is, the pixel electrode arranged in each sub-pixel is planar The first electrode 22 of the structure is electrically connected to the drain of the TFT 29 .

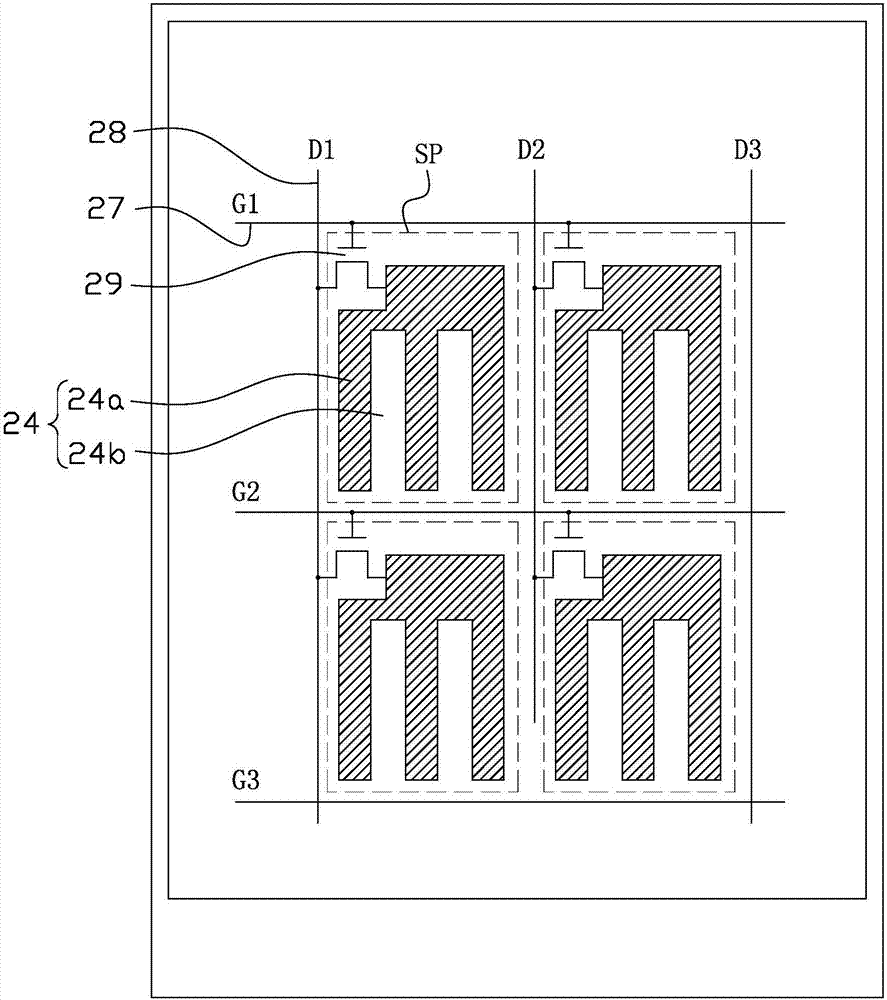

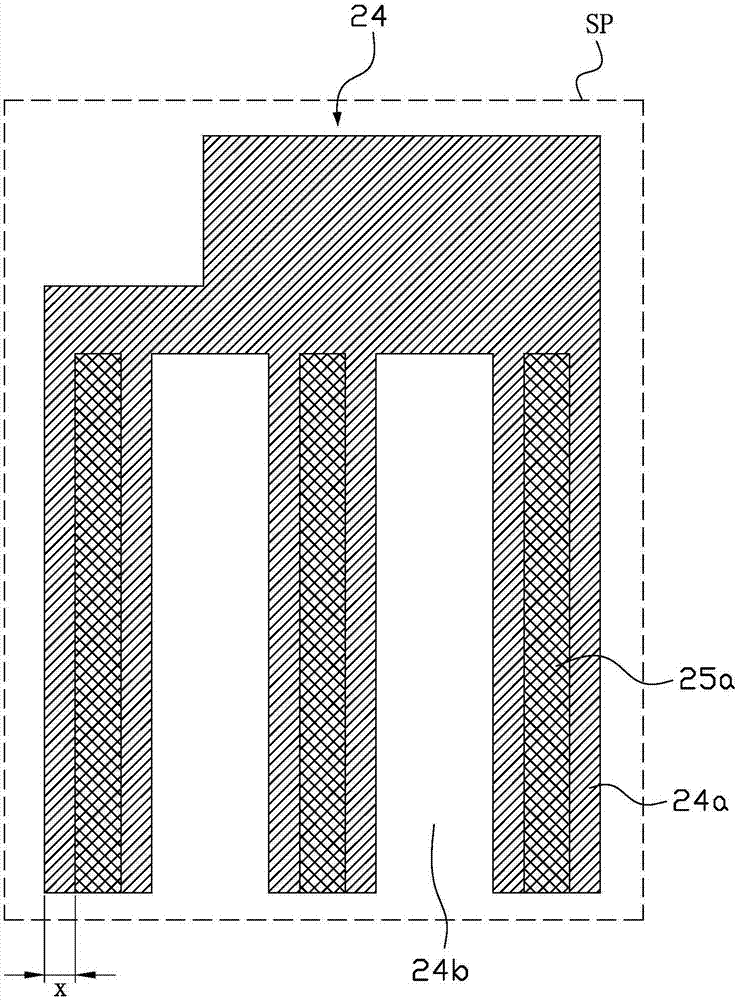

[0047] Figure 7 for Figure 5 The schematic diagram of the plane structure of the second electrode and the insulating protective layer, please combine Figure 7 In this embodiment, the second electrode 24 serving as a common electrode includes a plurality of electrode strips 24a spaced apart from each other in eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com