slider for zipper

A slider and zipper technology, applied in applications, apparel, sliding fastener elements, etc., can solve problems such as reduced availability of zippers, and achieve the effect of ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

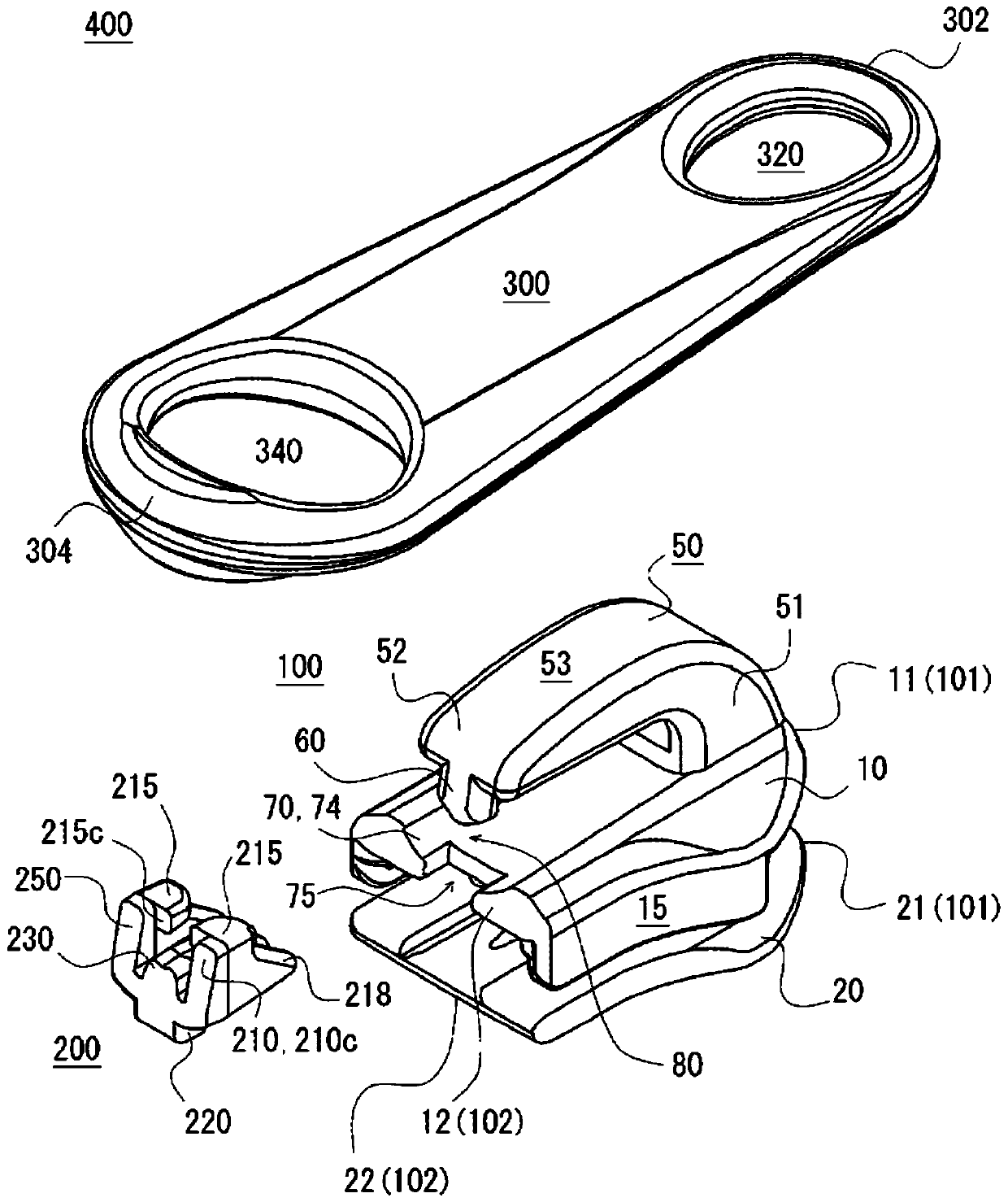

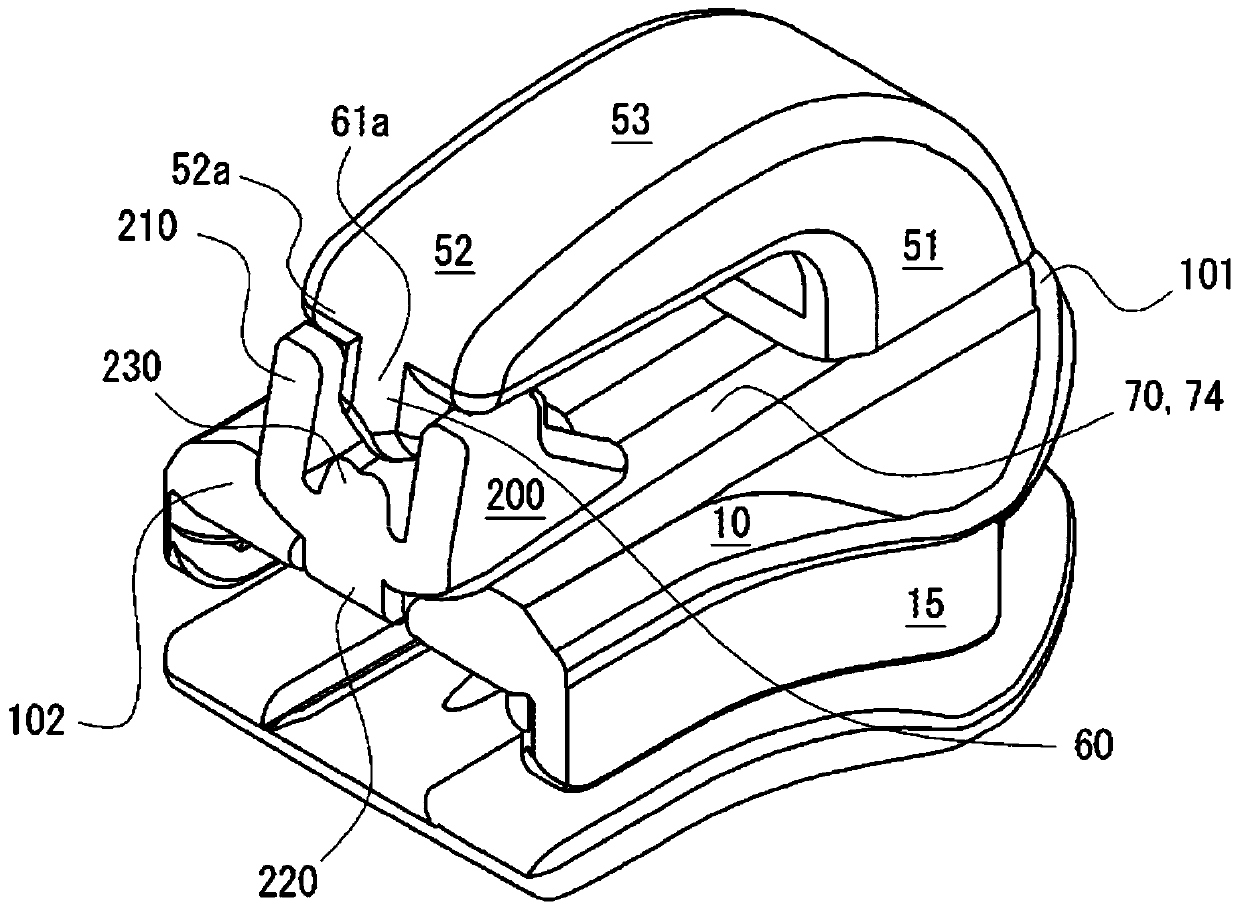

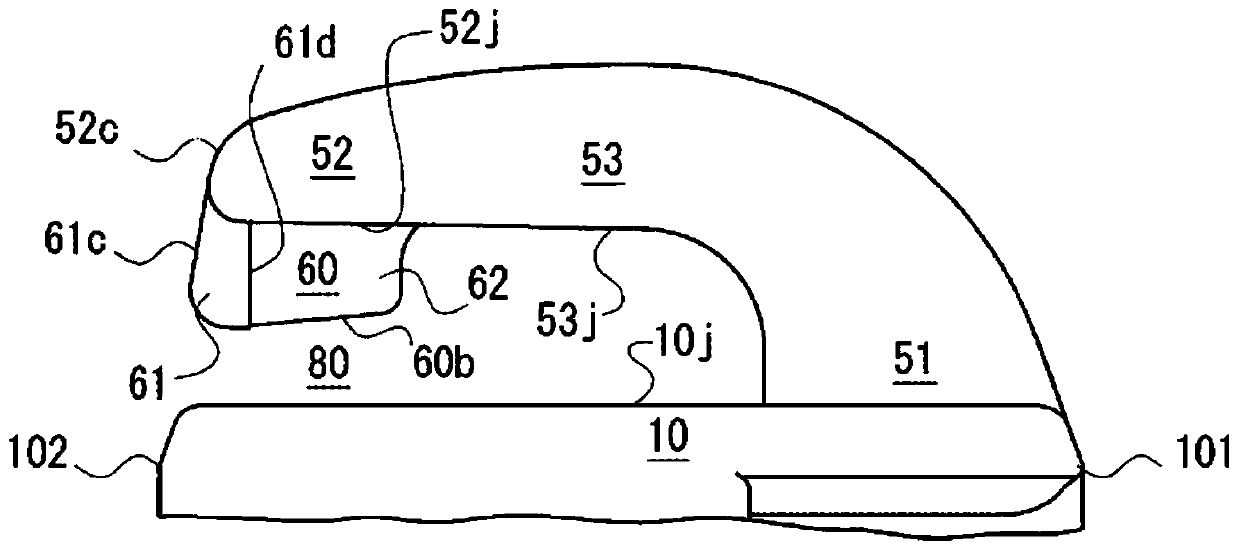

[0040] refer to Figure 1 to Figure 10 The first embodiment will be described. figure 1 It is a schematic exploded perspective view of a slider with a pull tab. figure 2 It is a schematic perspective view of a slider with a pull tab, and the illustration of the pull tab is omitted for convenience of illustration. image 3 is a schematic partial side view of the slider body of a slider with a pull tab, particularly showing the sides of the upper wing and the tab mounting post. Figure 4 It is a schematic partial cross-sectional schematic diagram of the slider main body of the slider with a pull tab, and particularly shows the cross-section of the upper wing plate and the tab mounting column. Figure 5It is a schematic diagram which compared the rough partial side view of the slider main body of the slider with a slider, and the partial cross-sectional schematic diagram. Figure 6 It is a back view of the closure member of the slider with a pull tab, and the pivoting form of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap