Metal printed circuit board having aperture reflection plane and manufacturing method

A technology of printed circuit boards and manufacturing methods, which is applied in the direction of printed circuit manufacturing, printed circuits, printed circuits, etc., can solve problems such as uneven structure, additional manufacturing costs, and influence on color temperature, so as to improve reflection efficiency, reduce costs, and prevent diffusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following describes in detail a preferred embodiment of the metal printed circuit board with a reflective surface with holes and its manufacturing method according to the present invention.

[0056] Through the detailed description of the following embodiments, the characteristics and advantages of the metal printed circuit board with a reflective surface with holes and its manufacturing method according to the present invention will be more clarified.

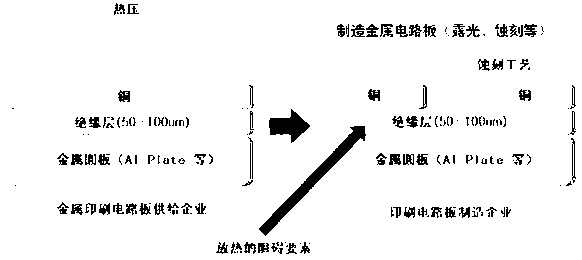

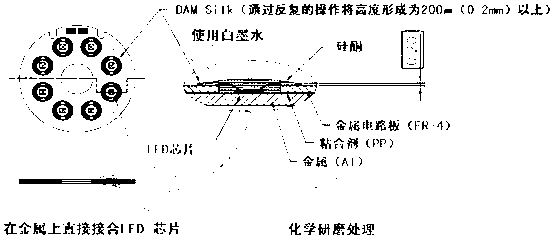

[0057] Figure 2a to Figure 2g It is a cross-sectional view of the manufacturing process of a metal printed circuit board with a hole reflecting surface according to the present invention.

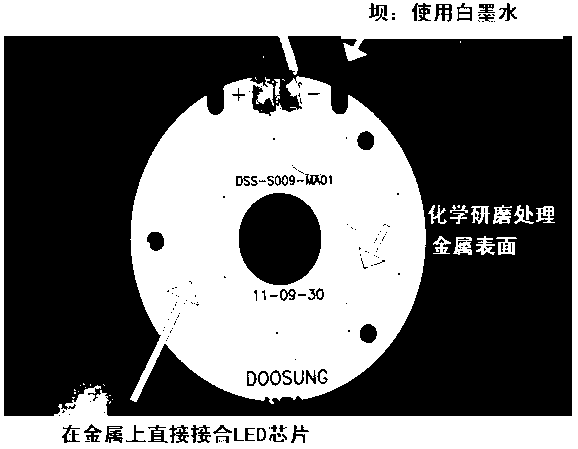

[0058] In the present invention, the process of forming the primary reflective structure is formed by processing the surface of the metal circular plate by processes such as chemical polishing, rather than by expensive processes such as gold plating. In the process of forming the secondary reflective structure, the reflective surface i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap