Apparatus for applying viscous materials

A viscous material and coating technology, which is applied to the device for coating liquid on the surface, spraying device with movable outlet, spraying device, etc., can solve the problem of inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

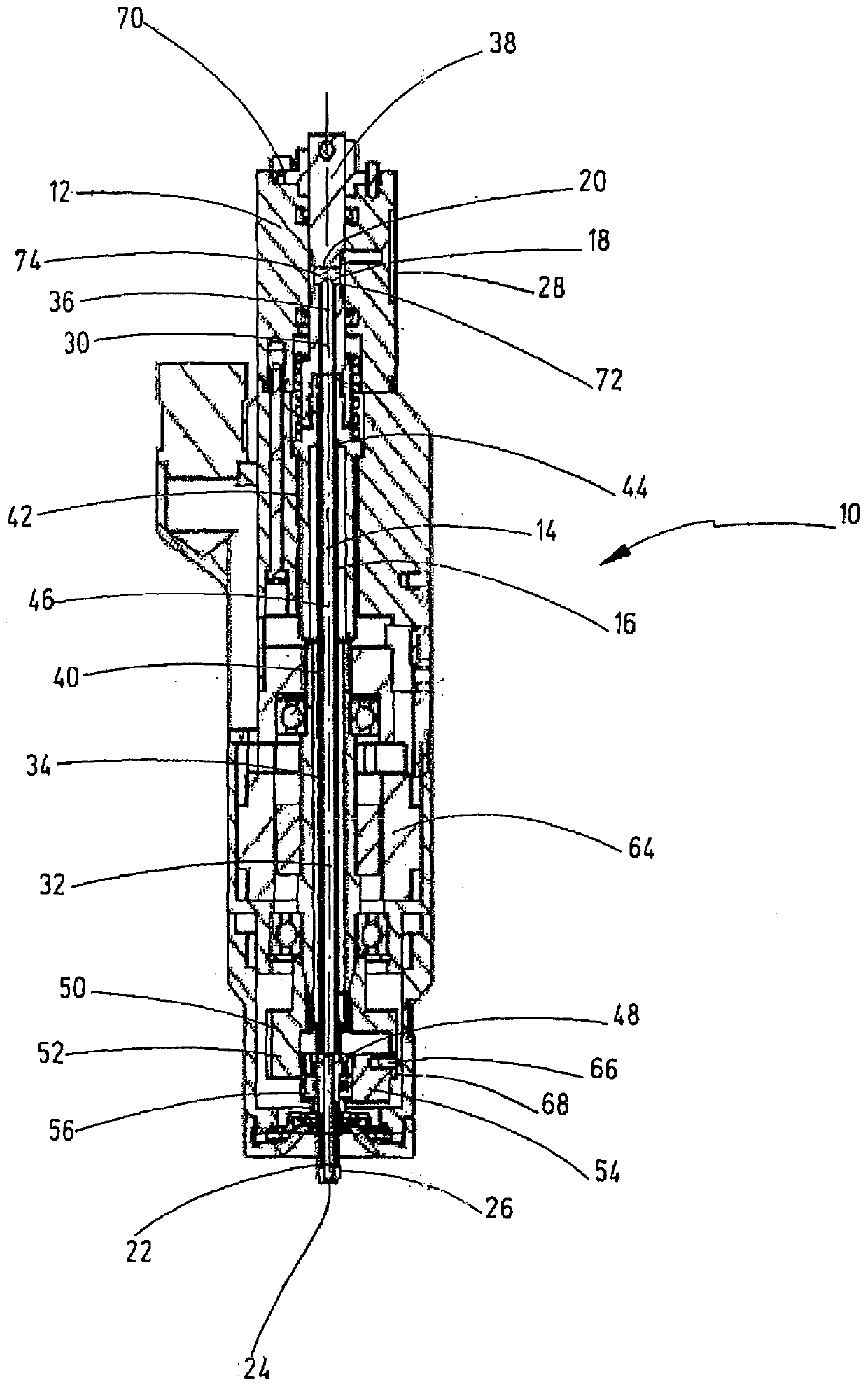

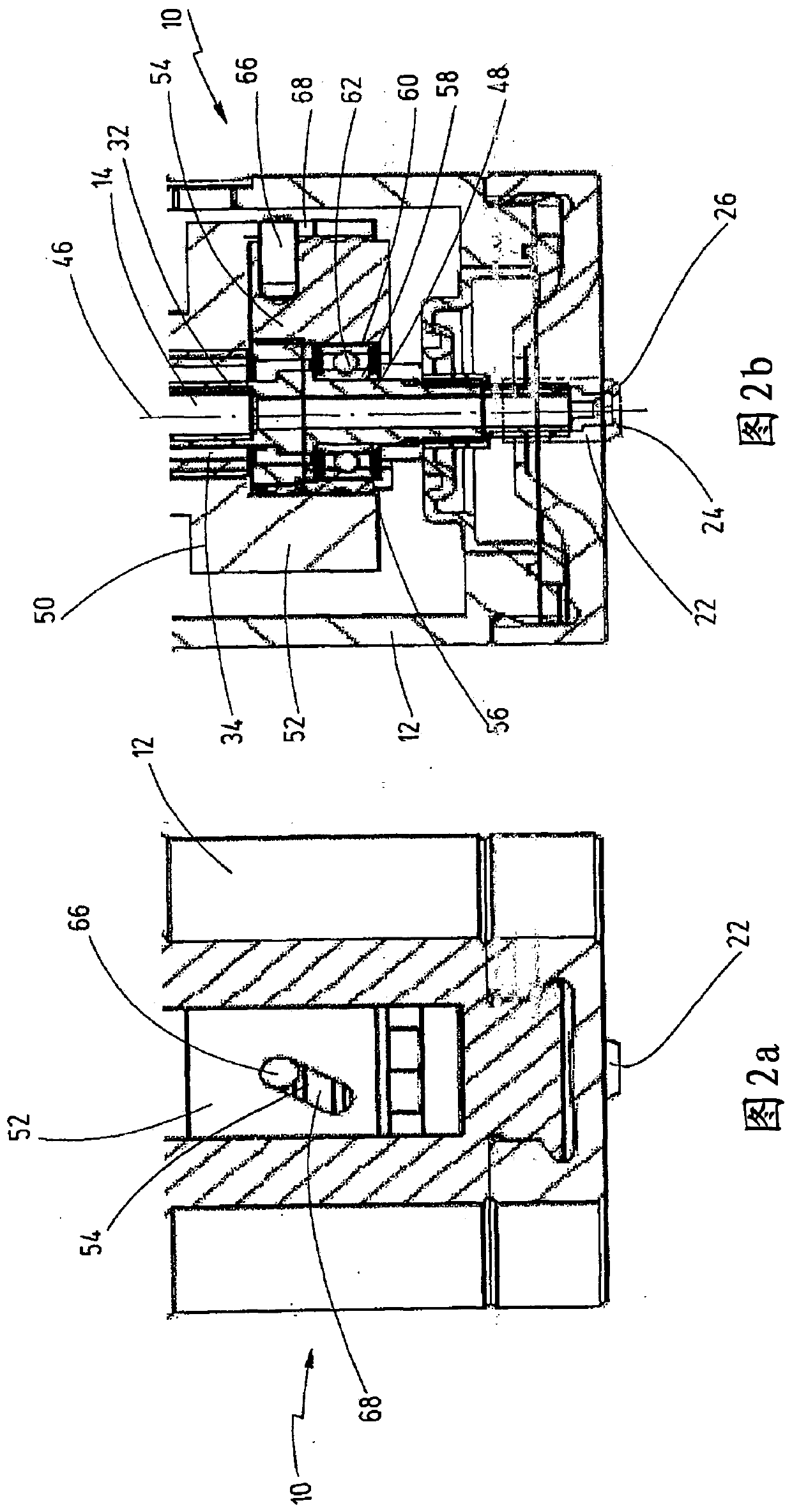

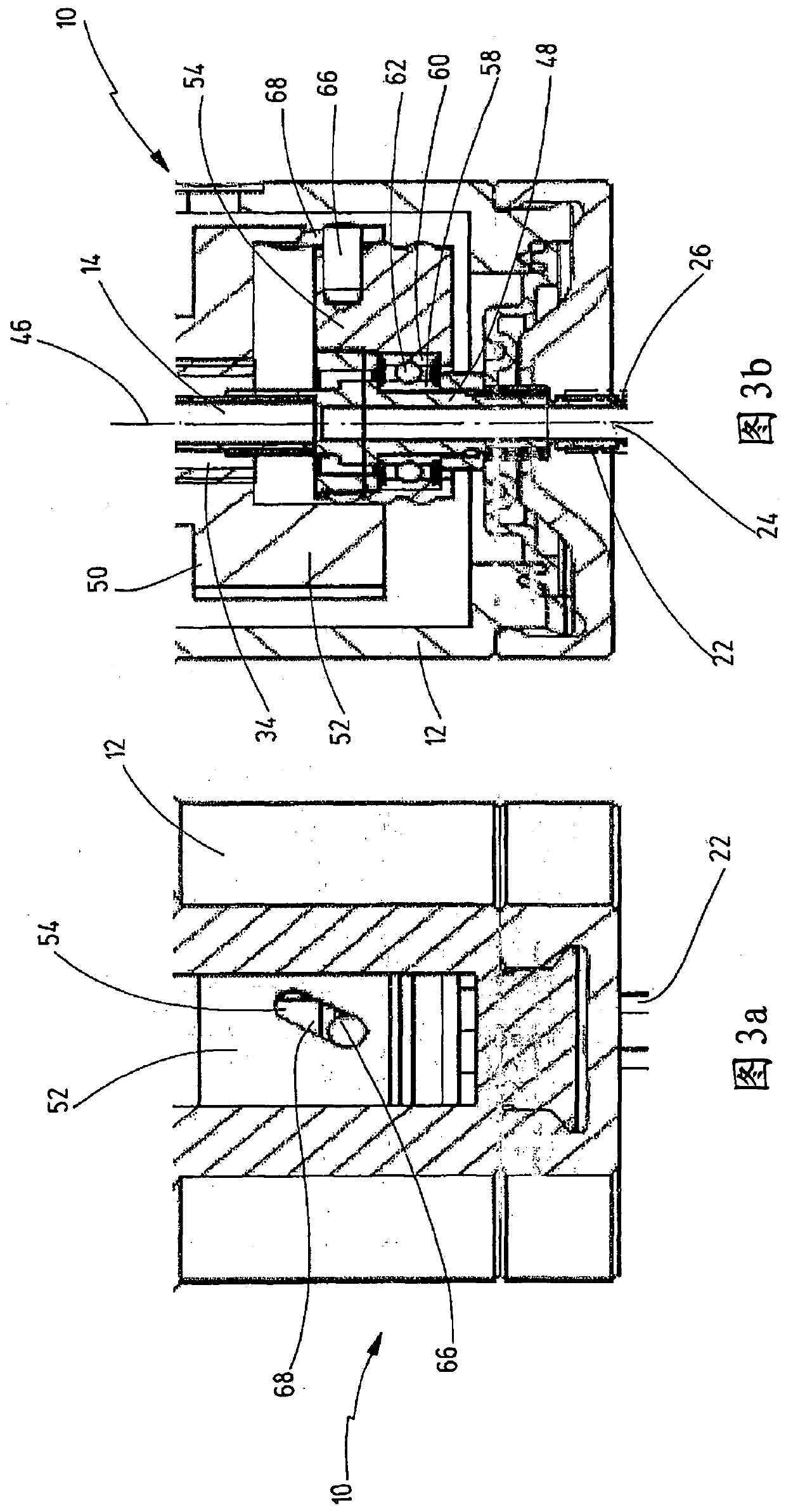

[0018] The device 10 shown in the drawing is used for applying an adhesive material, for example an adhesive, to a workpiece. It has a housing 12 in which an application tube 16 annularly surrounding an application channel 14 for the viscous material is accommodated. The application tube 16 is multi-part and extends from a first end 20 having a material inlet opening 18 to a second end 26 formed by an application nozzle 22 comprising a material outlet opening 24 . Viscous material is delivered to the material inlet opening 18 via a material delivery connection 28 in the housing 12 . The application tube 16 has a starting region 30 starting from the first end 20 , which is connected to the housing 12 , and an end region 32 which extends to the second end 26 and which is connected to the housing. 12 are arranged at a distance and are surrounded by an annular gap 34 over the largest part of their length. The start region 30 is partially formed by a first pipe section 36 to whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com