Method and device for finish machining of peripheral surfaces of rotationally symmetrical workpiece sections

A rotationally symmetric, polishing tool technology, used in machine tools, ultra-finishing machines, metal processing equipment, etc. designed for grinding the rotating surface of workpieces, and can solve problems such as inability to obtain surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

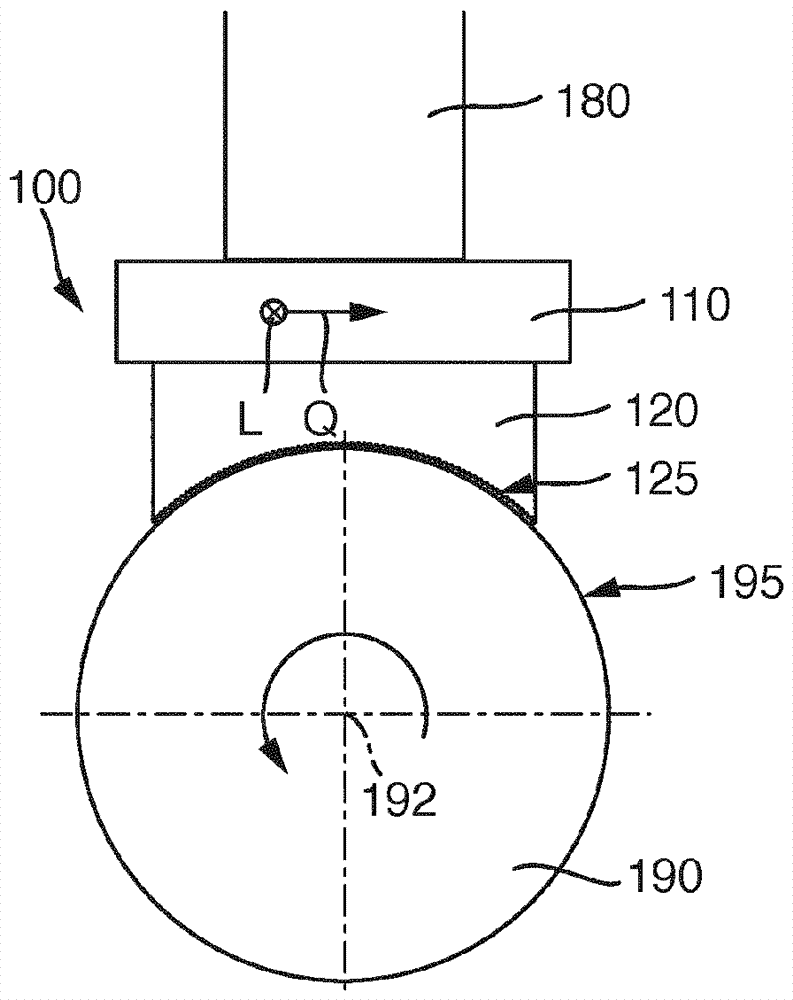

[0025] according to figure 1 and 2 Some associations and concepts that are helpful for understanding the implementation forms of the present invention are explained. here, figure 1 A side view of a typical machining situation is shown in an exemplary embodiment of a method for polishing a peripheral surface 195 of a rotationally symmetrical workpiece section on a workpiece 190 . The workpiece is rotated at a constant rotational speed by means of a rotary device for generating rotational motion of the workpiece about a workpiece rotational axis, or workpiece axis 192 . The workpiece section to be machined can be, for example, a main bearing of a crankshaft or a bearing surface of another shaft, for example a camshaft or a balancing shaft.

[0026] In order to cause material erosion on the workpiece section by means of polishing, the polishing tool 100 is pressed against the peripheral surface to be processed or the workpiece section to be processed with a contact force F a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com