Tires with improved wet grip in a partially worn state

A tire and wear level technology, applied in tire parts, tire tread/tread pattern, vehicle components, etc., can solve problems such as decreased effectiveness and danger, and achieve good water removal and improved water removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

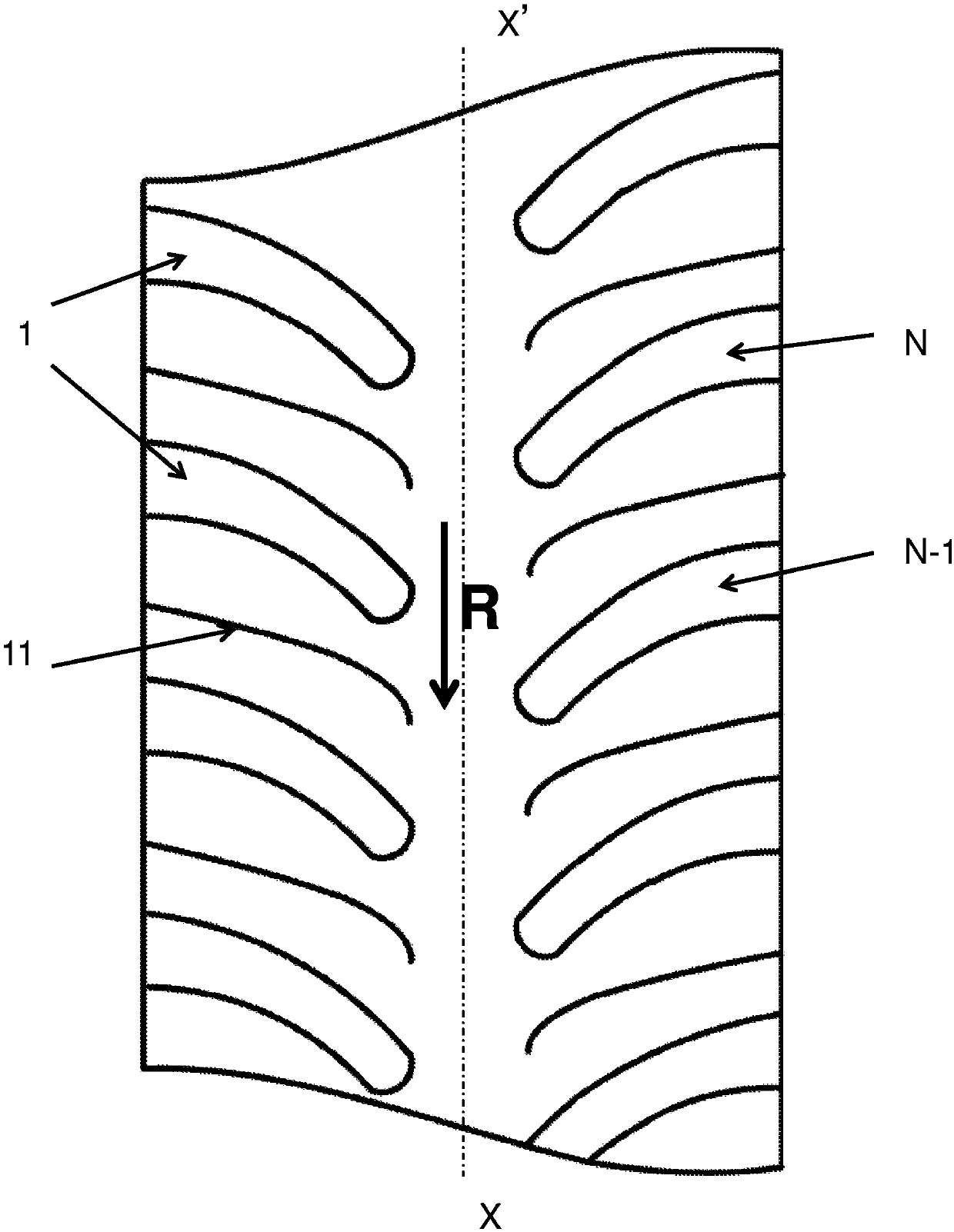

[0035] figure 1 The tread of a tire according to the invention is schematically depicted in a new state.

[0036] This tread contacts the road while driving. It comprises a plurality of main grooves 1 arranged on each side of the mid-plane X-X' and having N main grooves 1 on each side. Each of these main grooves 1 opens axially (in the direction of an axis) to the outside of the tread, the axis being defined in a direction parallel to the axis of rotation of the tyre. This allows water to be removed towards the outside of the tire when the vehicle is running, that is to say starting from the end of the groove closest to the axis X-X' towards the end of the groove furthest from the axis X-X'. Each of these main grooves extends axially towards the mid-plane XX' such that the plurality of main grooves form a generally V-shaped pattern. The orientation of the V indicates the preferred direction of rotation of the tire. This direction of rotation is also indicated by arrow R. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com