LNG carrier vessel, and method for manufacturing such an LNG carrier vessel

A transport ship and hull technology, applied in the field of LNG transport ships, can solve the problems of reducing the processing area of the workbench and the inability to realize the LNG storage capacity, etc., and achieve the effect of optimizing the ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

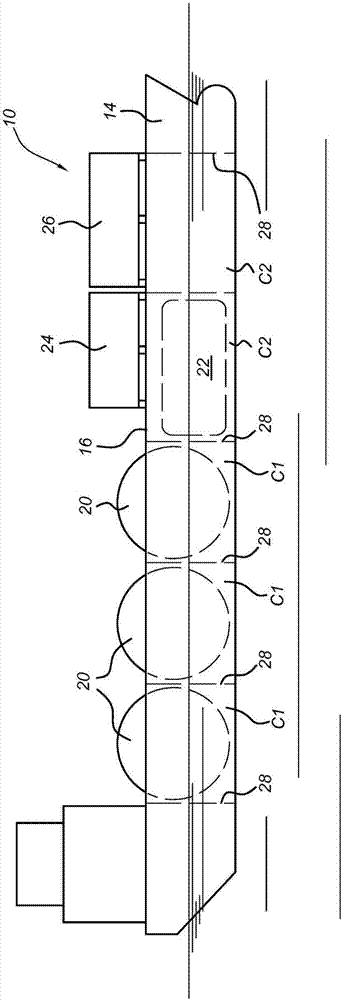

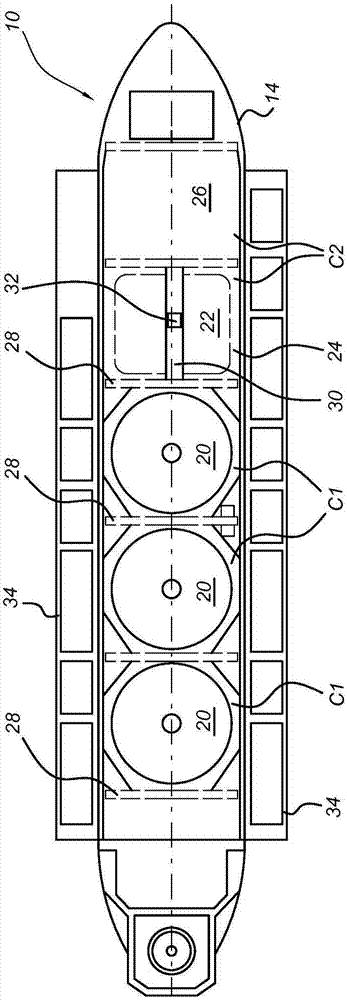

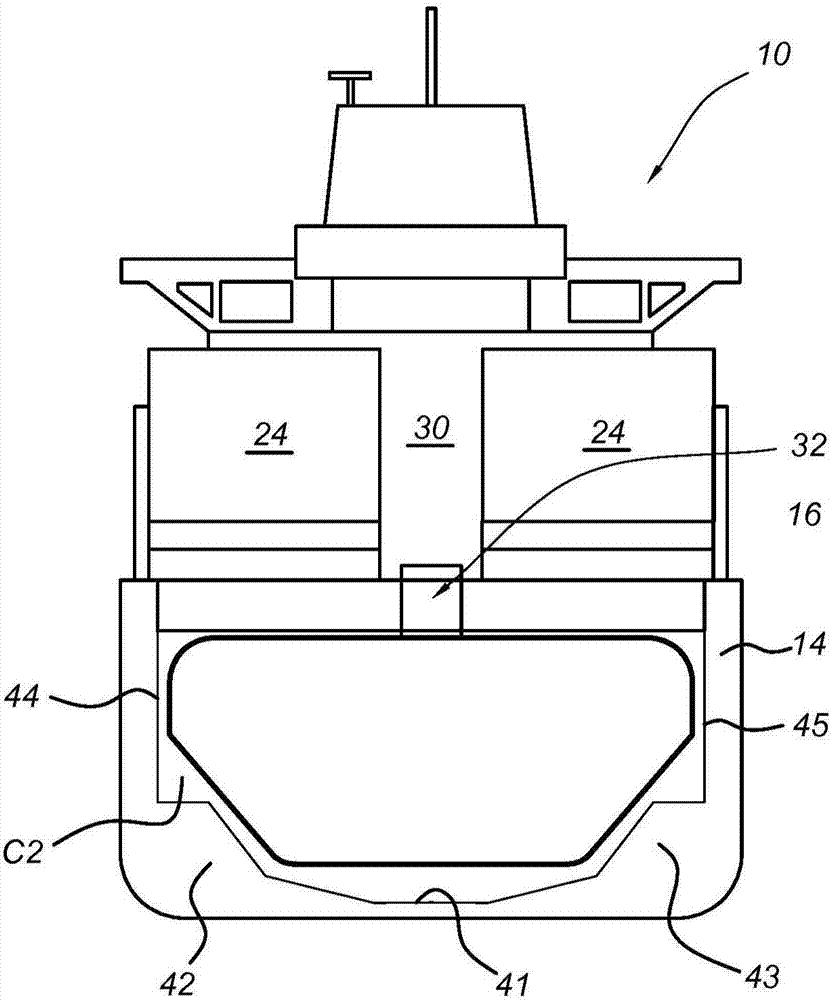

[0048] figure 1 A side view of an LNG carrier 10 according to an embodiment of the present invention is shown.

[0049] LNG carrier 10 includes a hull 14 and a main deck 16 .

[0050] The LNG carrier 10 is also provided with storage capacity for LNG through a plurality of LNG tanks 20 , 22 . LNG tanks 20, 22 are installed in the cargo hold of each of the carriers.

[0051] The plurality of LNG tanks includes one or more LNG tanks 20 of a first spherical type arranged in a cargo hold C1 (indicated as main cargo hold) within the hull 14 of the LNG carrier 10 . The size of the spherical LNG tank 20 is determined such that a part of the ball protrudes above the main deck 16 .

[0052] According to the prior art, spherical LNG tanks are called Moss-type LNG tanks.

[0053] According to the present invention, the LNG carrier 10 also includes one or more second non-spherical LNG tanks 22 in one or more of the remaining cargo tanks C2 (denoted as secondary cargo tanks) of the LNG ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com