Handling device with suction cup for foodstuff

A technology for operating devices and food, applied in the direction of transportation and packaging, conveyor objects, load hanging elements, etc., which can solve the problems of time-consuming and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, the same elements are denoted by the same numerals and reference numerals and elements shown in more than one drawing will not be described repeatedly.

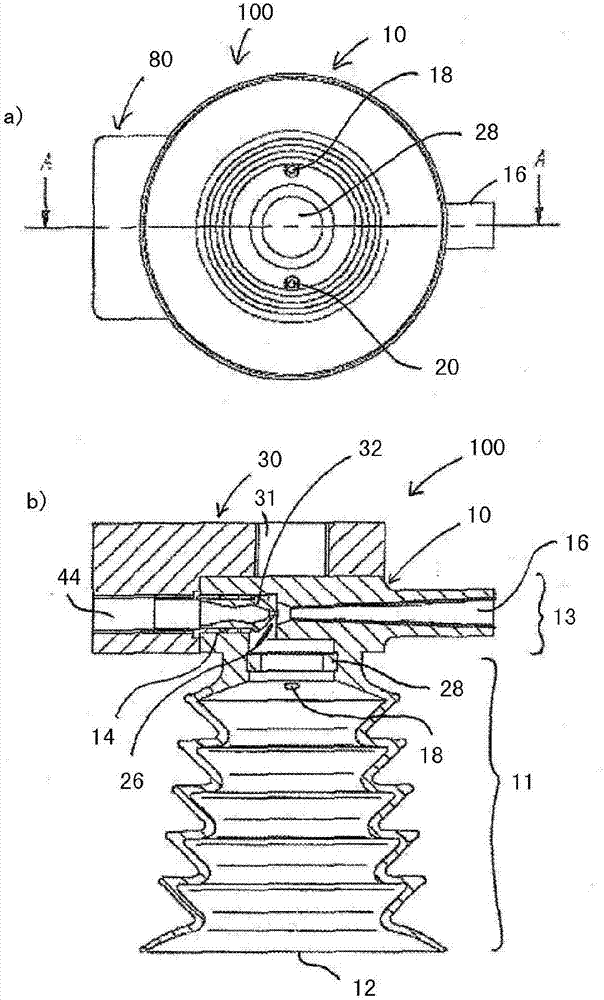

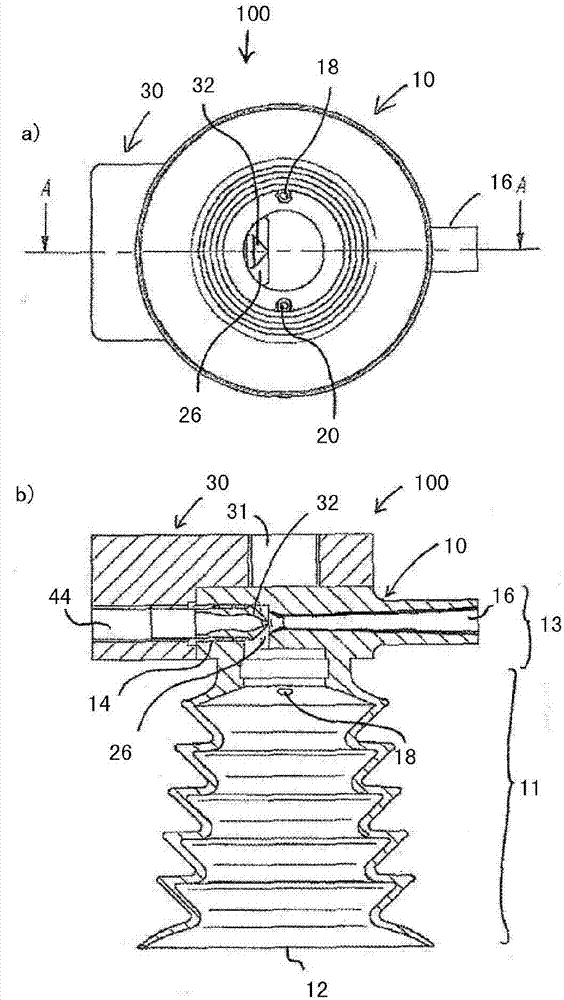

[0050] figure 1 a shows a bottom view of a first embodiment of an operating device 100 comprising a suction cup 10 and a plug connector 30 . The details of the suction cup 10 and the plug connector 30 will become clearer with reference to the following figures and descriptions.

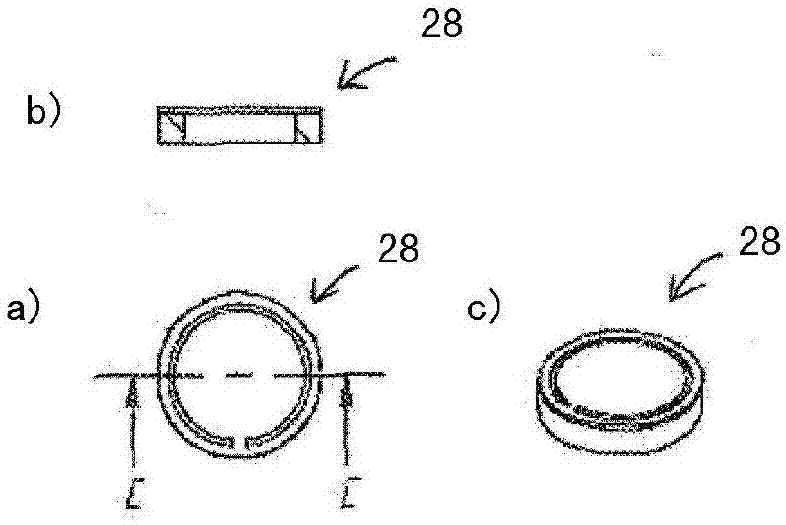

[0051] figure 1 The schematic diagram of the handling device 100 at a shows the interior of the suction cup 10 seen from below, ie its open end configured to contact the food product to be handled. In addition to the walls constituting the actual suction cup, the suction cup 10 comprises an outlet nozzle 16 located in the upper region of the suction cup 10 on the opposite side of the plug 30 attached to the suction cup 10 . exist figure 1 The check valve 28 is seen in a, which is located at the top of the actual suction cup an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com