Stop damper

A technology for shock absorbers and stoppers, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as limitations of shock absorption characteristics, achieve low structural cost, and be conducive to economical production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Identical components in different figures are always marked with the same reference numerals and are therefore generally only indicated or mentioned once.

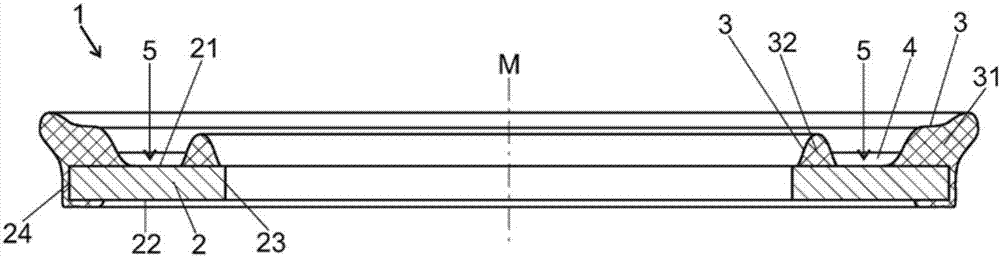

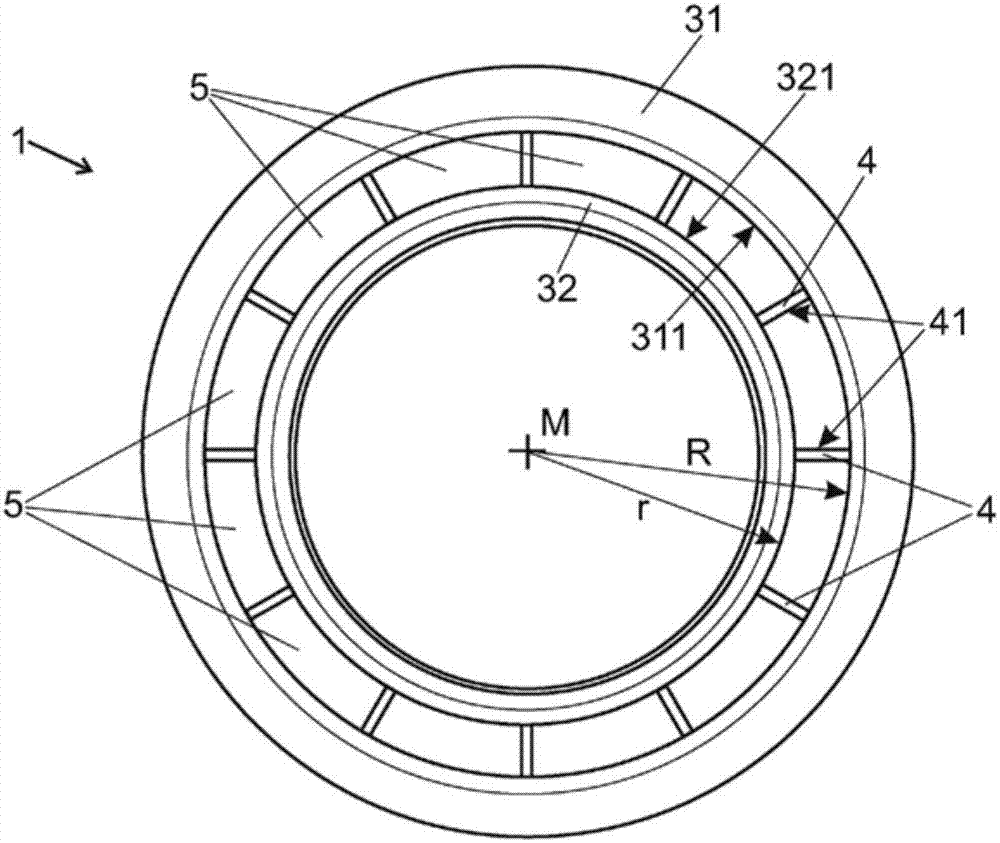

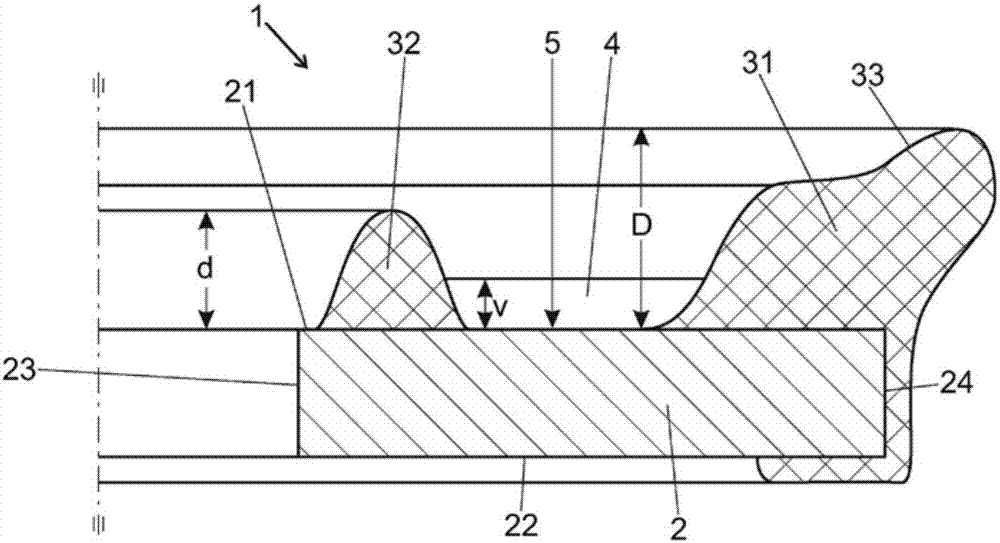

[0028] The stop damper 1 according to the invention is designed in the form of a ring or disk with a central axis M. The stop damper 1 comprises a carrier 2 which is formed in the form of an annular disk with a first front side 21 and a second, opposite front side 22 and inner and outer side surfaces 23 and 24 extending therebetween. The bracket 2 is preferably made of a bend-resistant, durable metal or plastic material.

[0029] On the first front side of the support 2 is mounted a shock absorbing element 3, preferably made of an elastomeric material, such as synthetic rubber and nitrile-butadiene rubber, which is softer than the material of the support 2 . The damping element 3 is bonded to the support 2 on the contact surface of the damping element, for example glued or sintered.

[0030] The damping element 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com